Hot Tapping and Line Plugging 4″

4″ Hot Tapping & Line Plugging

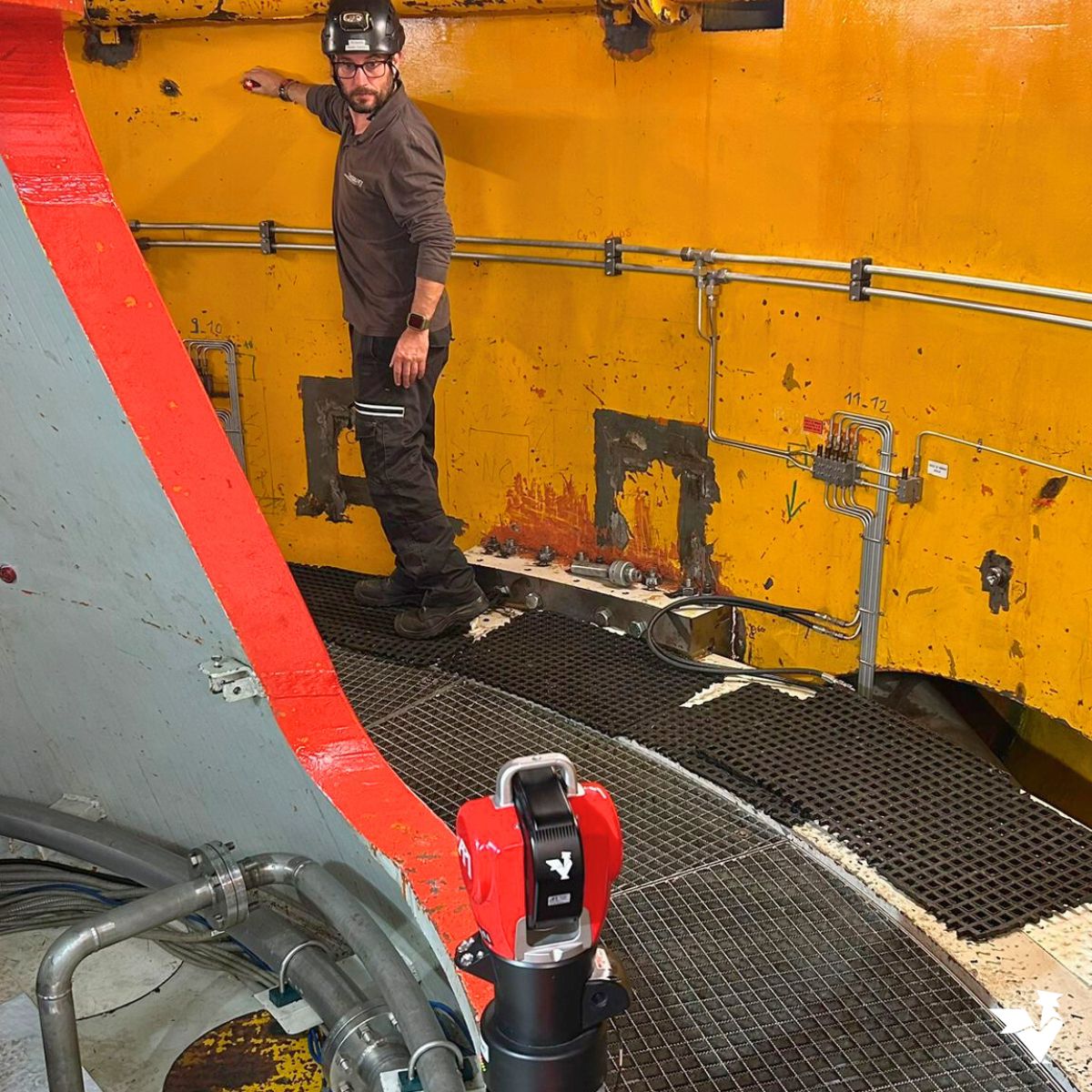

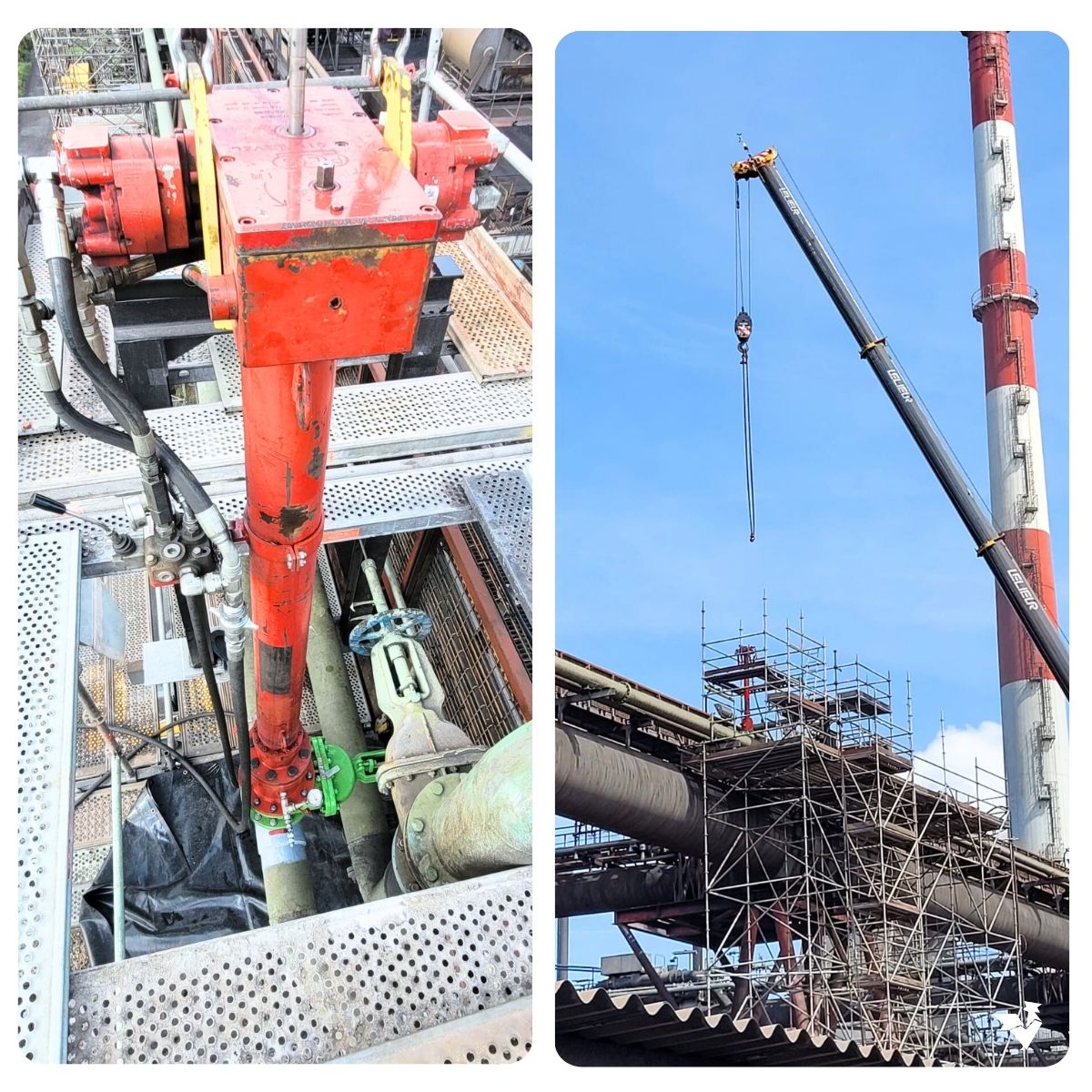

As part of a live water network intervention, we carried out a DN100 PN16 line plugging operation, enabling safe work without interrupting service.

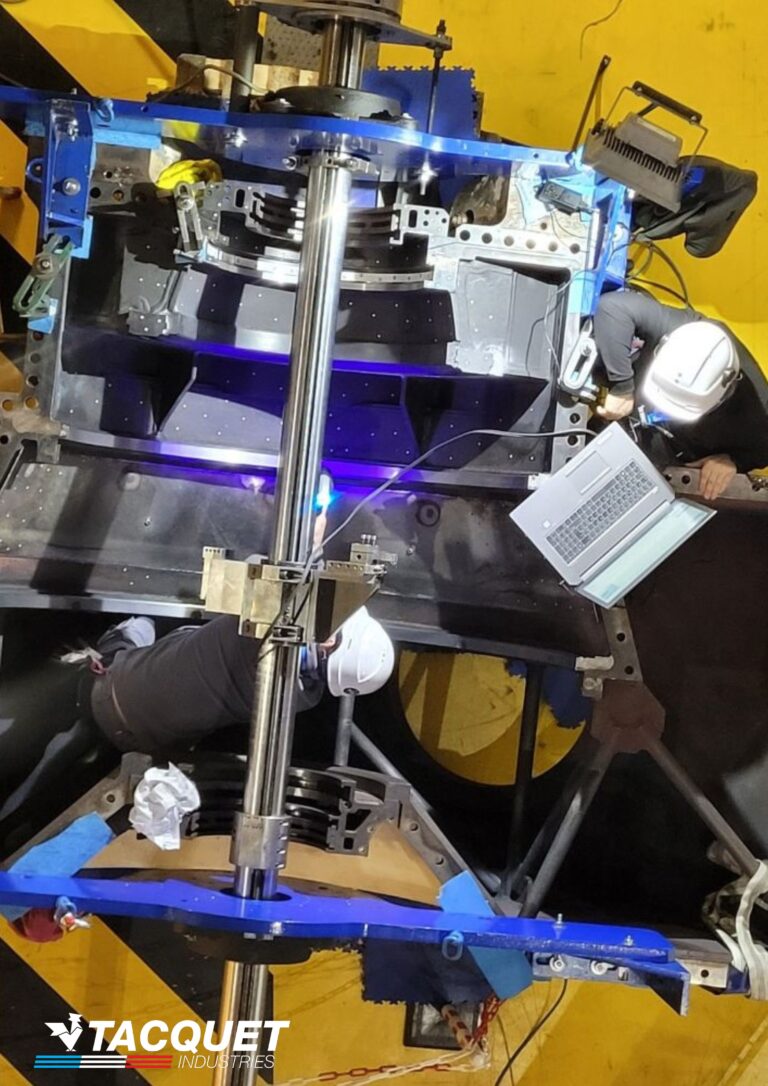

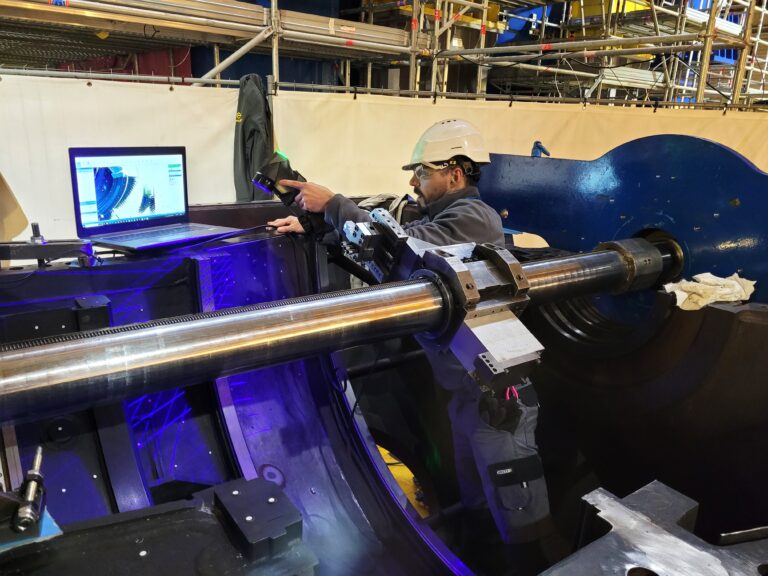

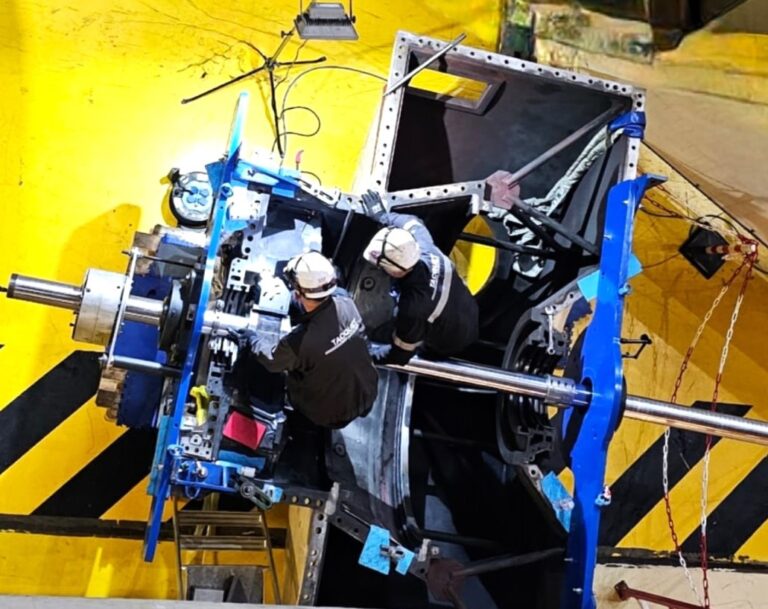

The operation began with the supply and installation of a full-encirclement tapping fitting and a full-bore valve. Once our teams and equipment were mobilized, a controlled under-pressure drilling was performed, preceded by a nitrogen tightness test.

In parallel, a mechanical saddle and a secondary 1″ valve were installed to allow for network purging. A second hot tap was carried out for this purpose.

The line plug was then inserted to isolate the targeted section, allowing downstream work to be conducted under optimal conditions. Continuous monitoring was ensured throughout the plugging phase. At the end of the intervention, the system was safely removed and all components dismantled with care.

This operation reflects our expertise in live network interventions, combining safety, precision, and technical control.

20 march 2025