8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

OUR EXPERTISE

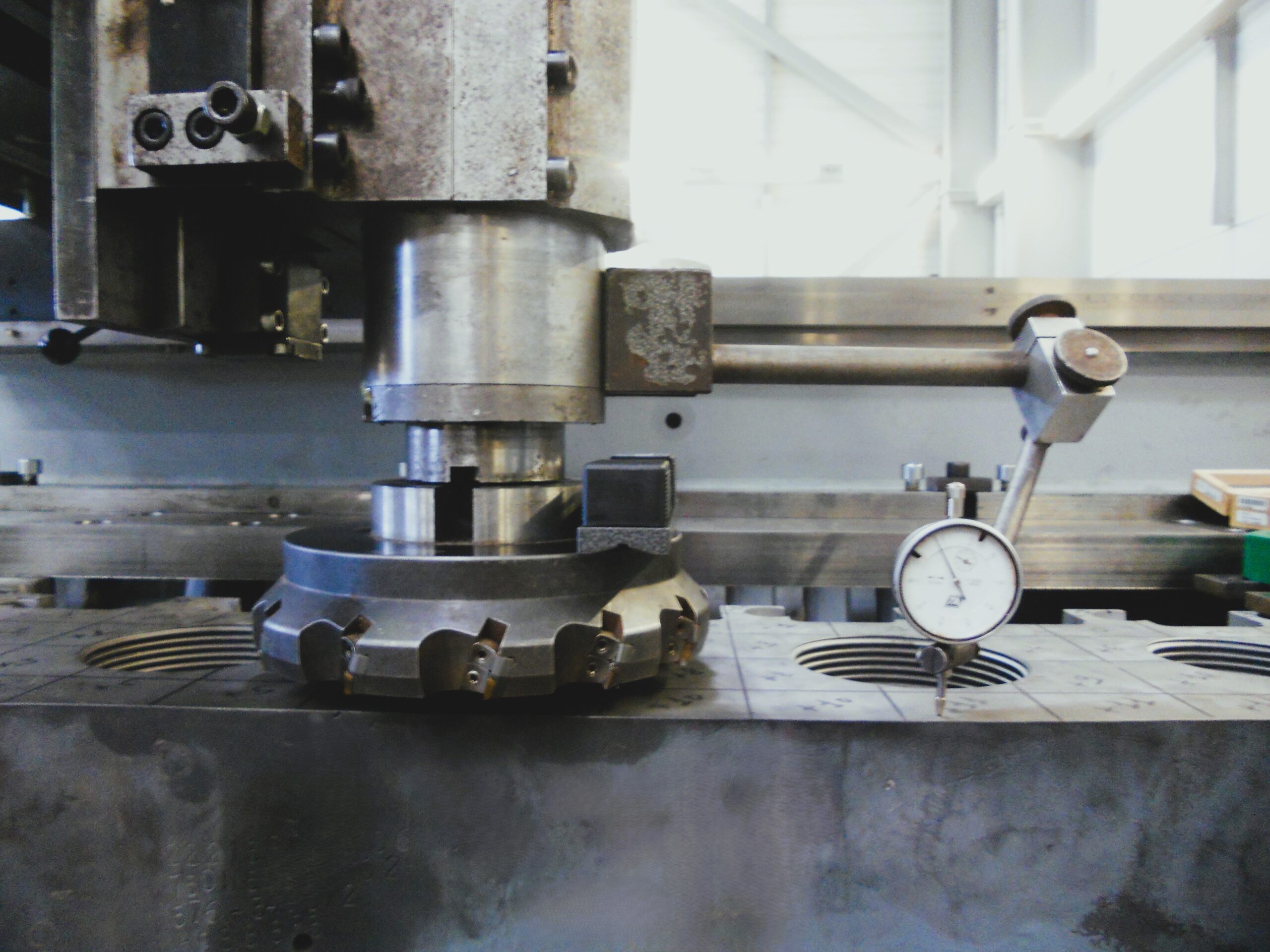

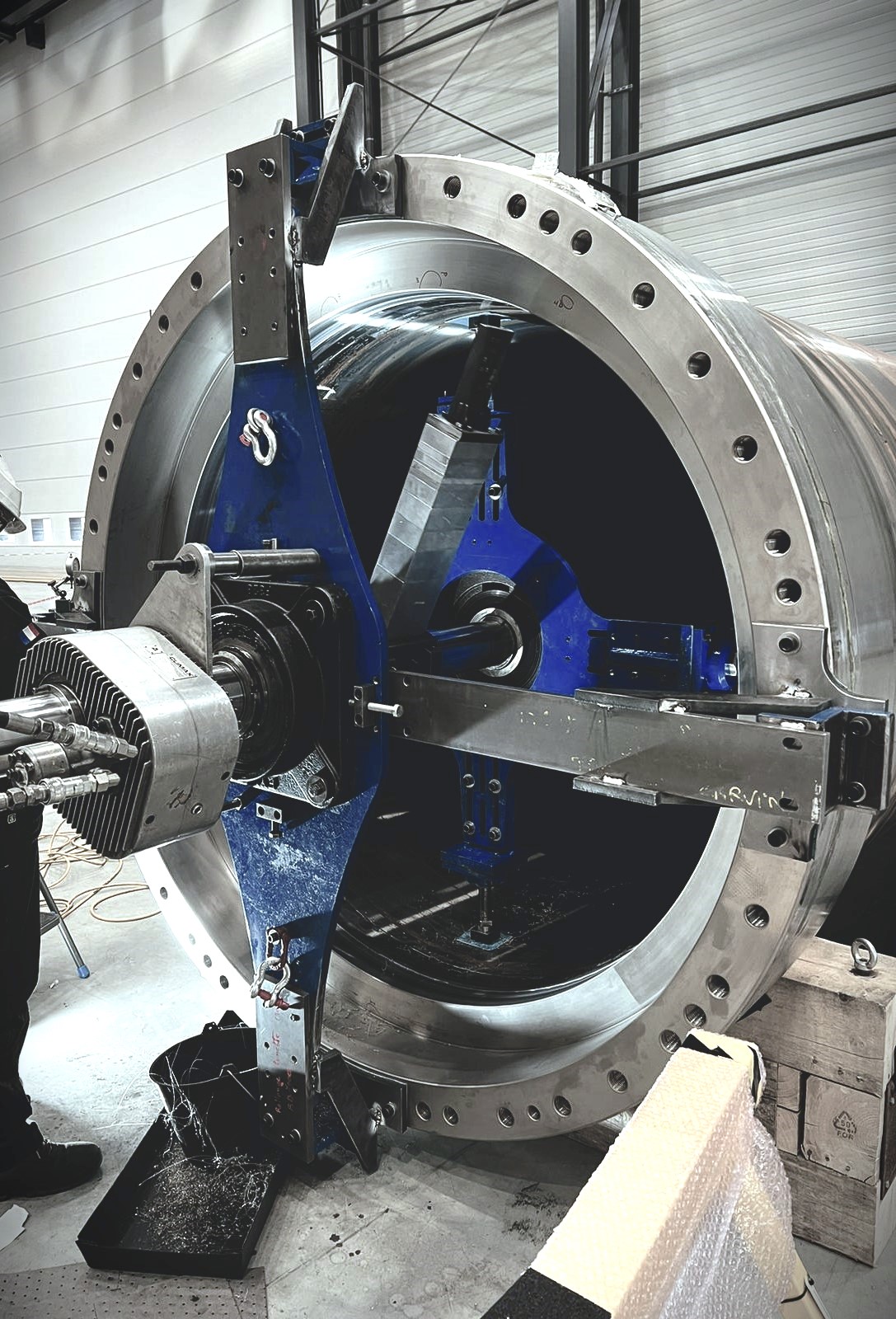

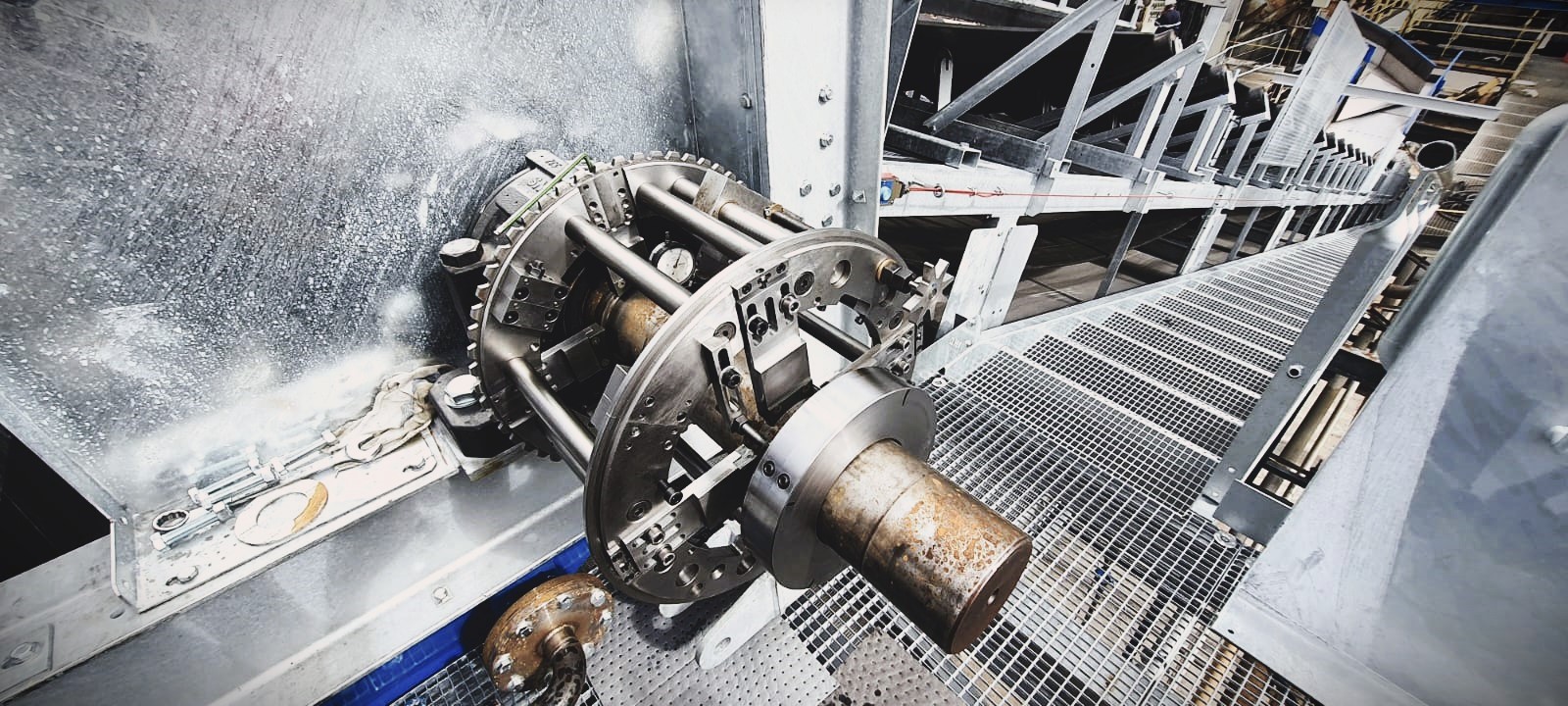

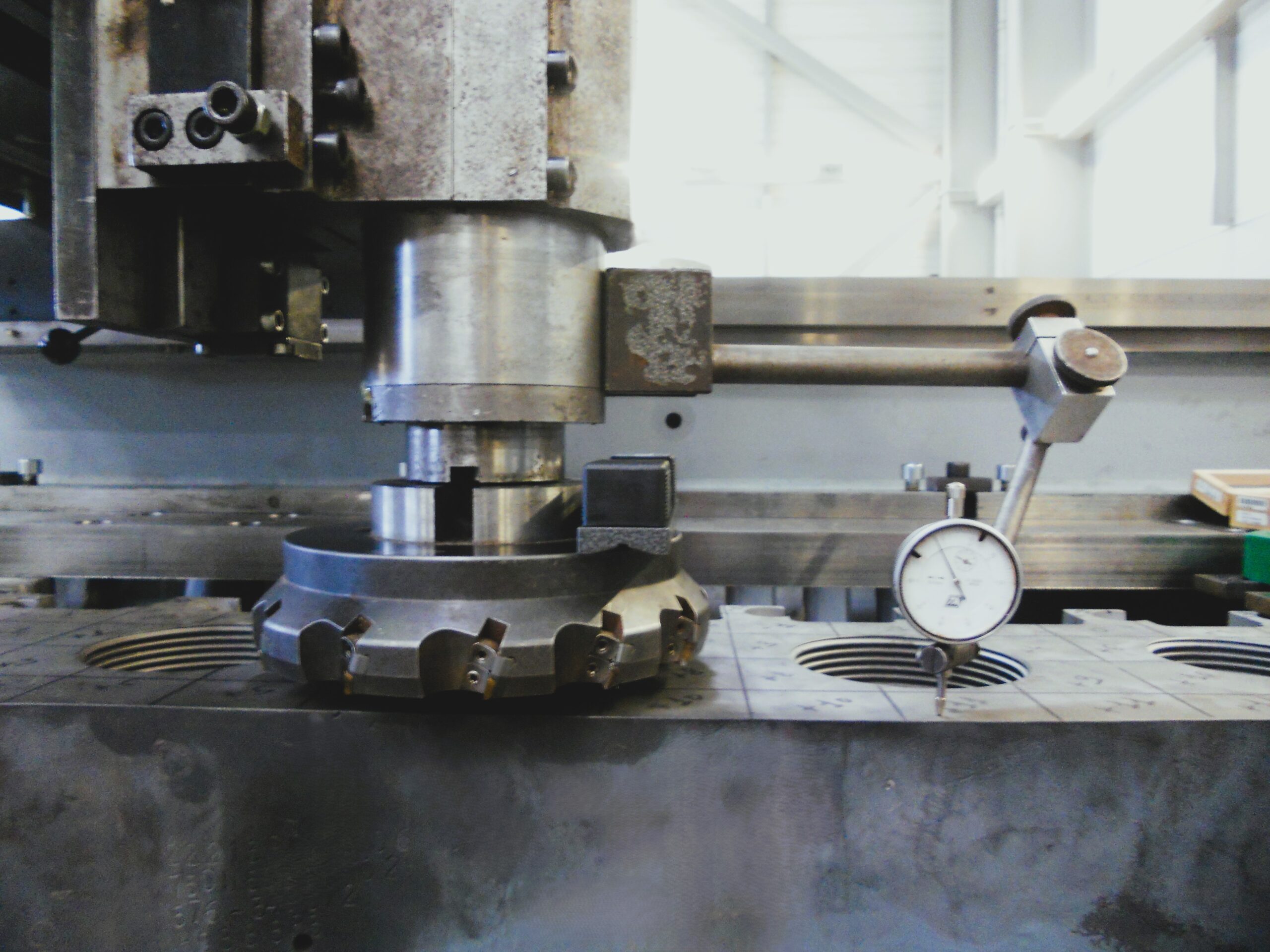

At TACQUET INDUSTRIES, we bring all our expertise and know-how to meet your on-site machining needs, both in France and internationally. Our mastery of operations such as milling, boring, facing, drilling and tapping allows us to work directly on your equipment — with no disassembly or extended production downtime.

Backed by proven technical know-how, we also carry out specialized services such as orbital grinding, hot tapping, and line plugging, even in the most demanding environments.

Our approach is based on a deep understanding of field constraints and a constant ability to adapt to your industrial requirements. We use high-precision equipment — including laser trackers — to ensure dimensional accuracy at every stage of the process. This industrial know-how is the result of 20 years of experience, a responsive team, and a fleet of over 200 portable machines.

Every intervention is designed to combine quality, efficiency, and safety, with a clear objective: to deliver reliable, fast, and durable on-site machining services. Our operational know-how translates into measurable results and strong customer satisfaction, across all industries.

Our commitment is driven by a strict QHSE (Quality – Health – Safety – Environment) policy, supported by certifications such as MASE and CEFRI. These standards ensure full compliance with the most demanding safety and environmental requirements, particularly during operations in sensitive or regulated environments.

At TACQUET INDUSTRIES, we bring all our expertise and know-how to meet your on-site machining needs, both in France and internationally. Our mastery of operations such as milling, boring, facing, drilling and tapping allows us to work directly on your equipment — with no disassembly or extended production downtime.

Backed by proven technical know-how, we also carry out specialized services such as orbital grinding, hot tapping, and line plugging, even in the most demanding environments.

Our approach is based on a deep understanding of field constraints and a constant ability to adapt to your industrial requirements. We use high-precision equipment — including laser trackers — to ensure dimensional accuracy at every stage of the process. This industrial know-how is the result of 20 years of experience, a responsive team, and a fleet of over 200 portable machines.

Every intervention is designed to combine quality, efficiency, and safety, with a clear objective: to deliver reliable, fast, and durable on-site machining services. Our operational know-how translates into measurable results and strong customer satisfaction, across all industries.

Our commitment is driven by a strict QHSE (Quality – Health – Safety – Environment) policy, supported by certifications such as MASE and CEFRI. These standards ensure full compliance with the most demanding safety and environmental requirements, particularly during operations in sensitive or regulated environments.

expertise expertise expertise expertise expertise expertise expertise expertise expertise