8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

8H30 – 12H30 / 14h – 17H30

from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

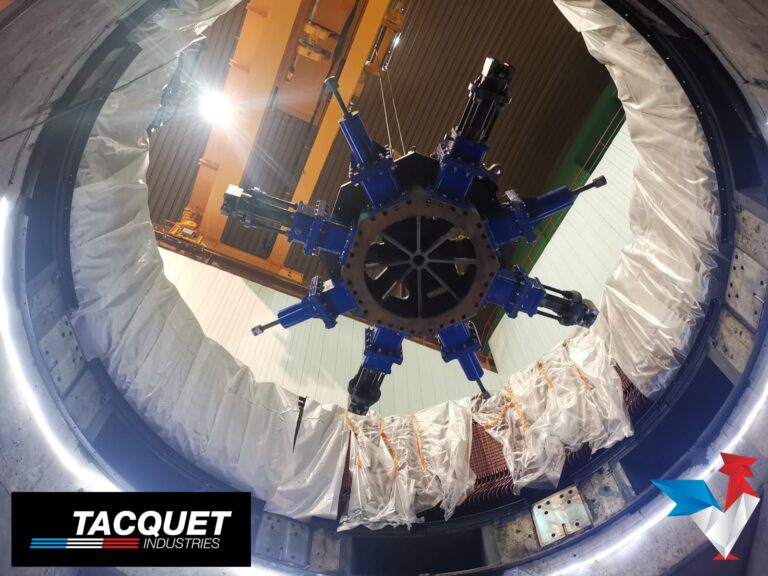

Machining key bars on stator with 2 parallel milling arms

Published on 21/02/2024

Machining key bars on stator with 2 parallel milling arms

A successful first for Isabelle ✅ 🚨

Machining key bars on stator with 2 parallel milling arms.

Diameter <5000mm

Height <3000mm

Material removal <17mm

800 M10 tapping holes

An extraordinary site for an extraordinary machine. ‼️‼️

A grueling construction site but we can be proud of us guys.🤩💪🏻

Thanks to the client for the trust and to all the colleagues who participated in this project.

🥇⛷️🎿🚁⚒️⚙️

Machining and grinding of the sidewall of bandage Ø4470

Published on 02/02/2024

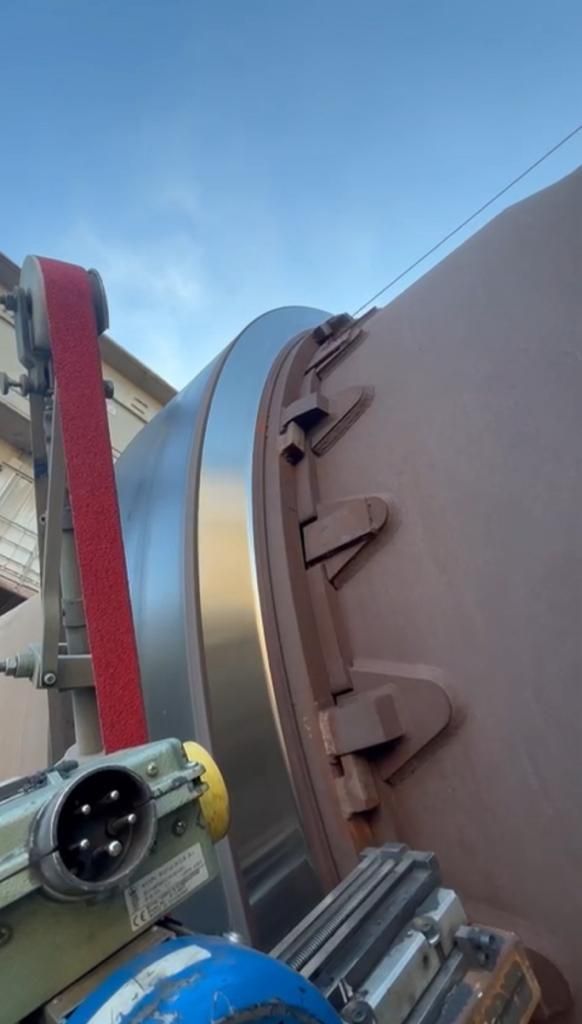

Machining and grinding of the sidewall of bandage Ø4470

New mission successfully completed 🏆

⚙ Machining and grinding of the sidewall of bandage Ø4470 on a width of 160mm with a slope at 11.5° and the advance stop of the furnace width 160mm at 11.5°

Congratulations to the TACQUET INDUSTRIES teams our technicians on site for their investment and performance 💪😎

ISABELLE in action

Published on 16/01/2024

ISABELLE in action !

😜 Here is, as promised, a small video 🎬 of the double milling of the stator bars in progress 💪 .

Keep it up, guys, it’s beautiful 😎 .

Thank you to JEUMONT Electric International and EDF Renouvelables for your trust.

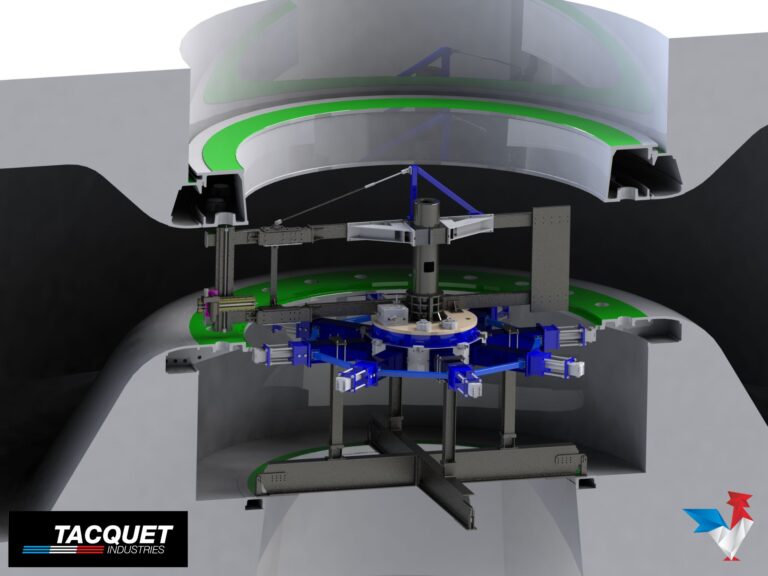

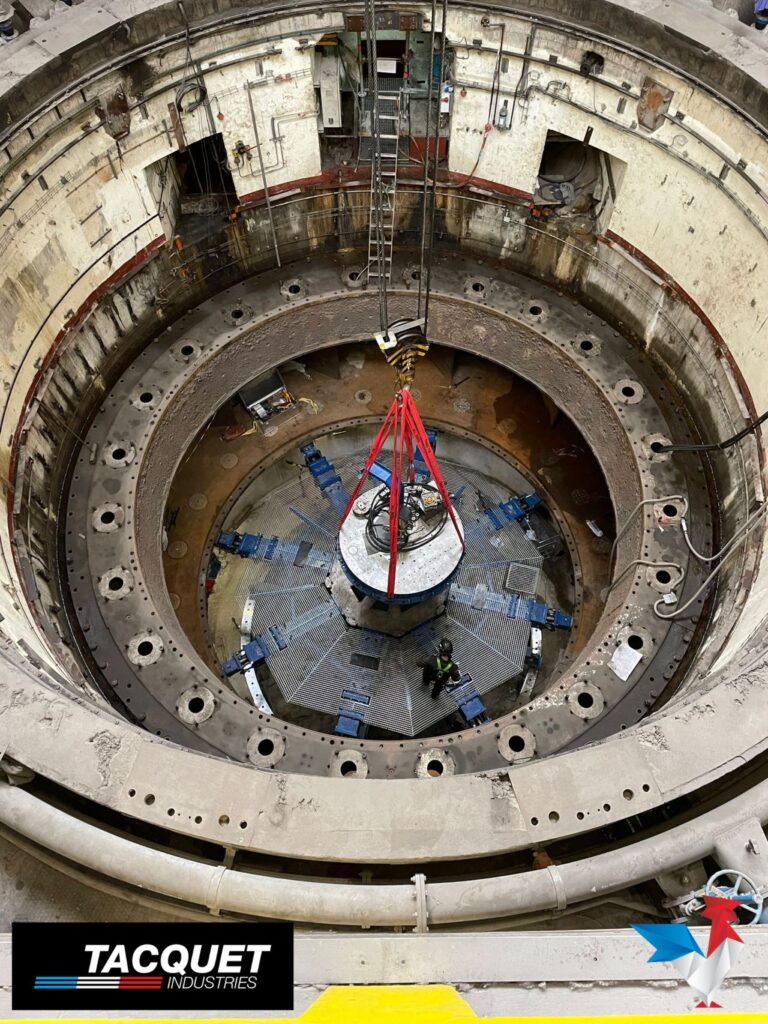

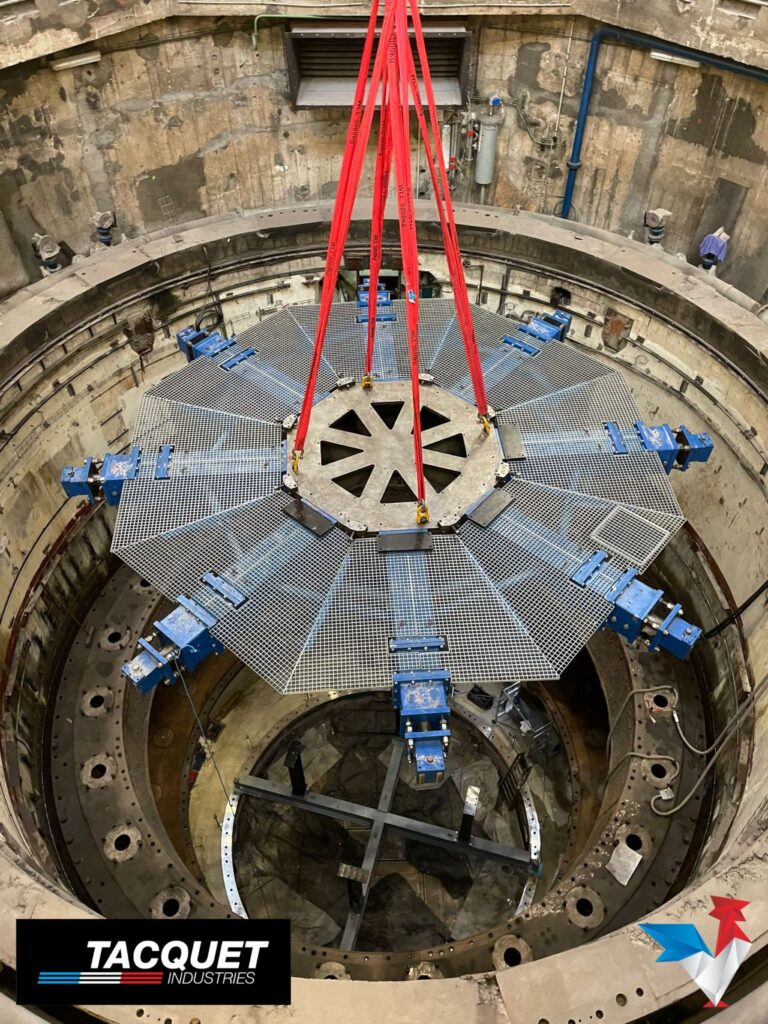

The process of making a Kaplan wheel mantle

Published on 16/01/2024

The process of making a Kaplan wheel mantle

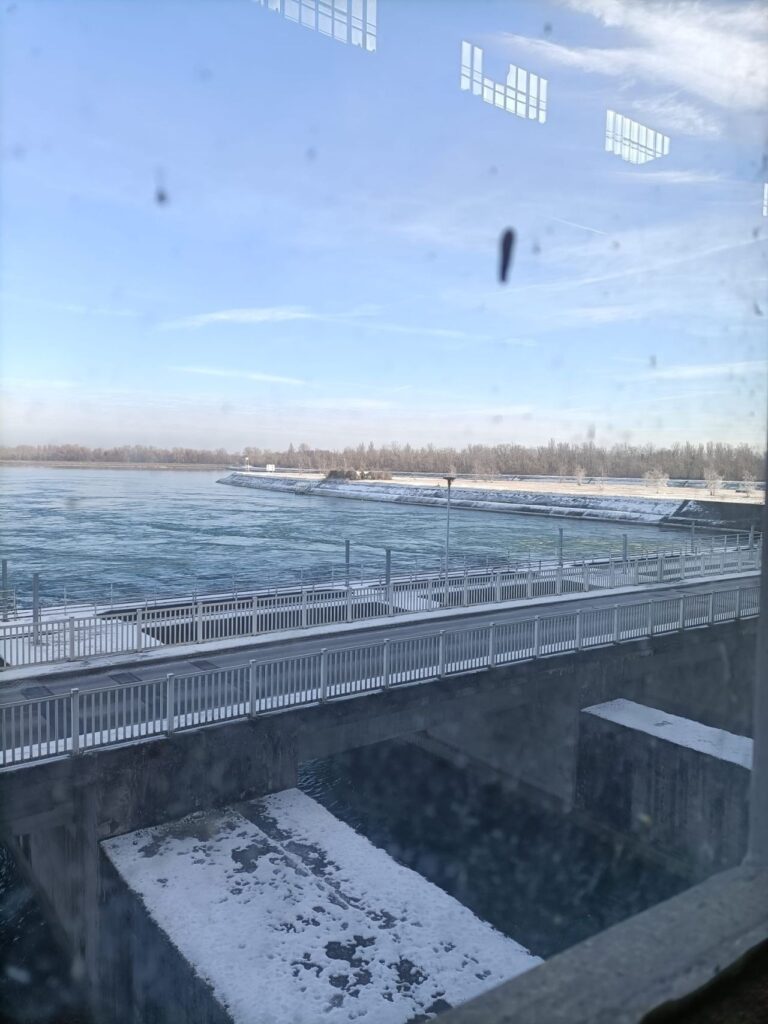

At the beginning of the year, the teams of TACQUET INDUSTRIES set up for the machining of a Kaplan wheel mantle of Ø6686mm 💧

Good luck to all and good job 🚧 🔧 ⚙

Turbine shaft repair

Published on 14/12/2023

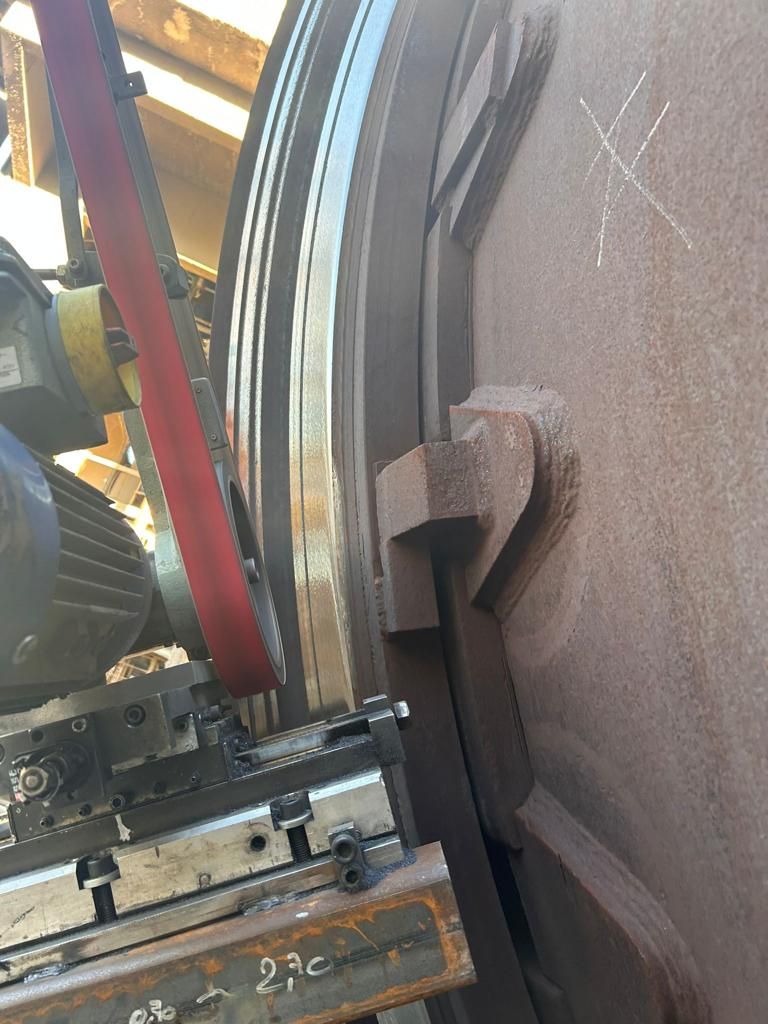

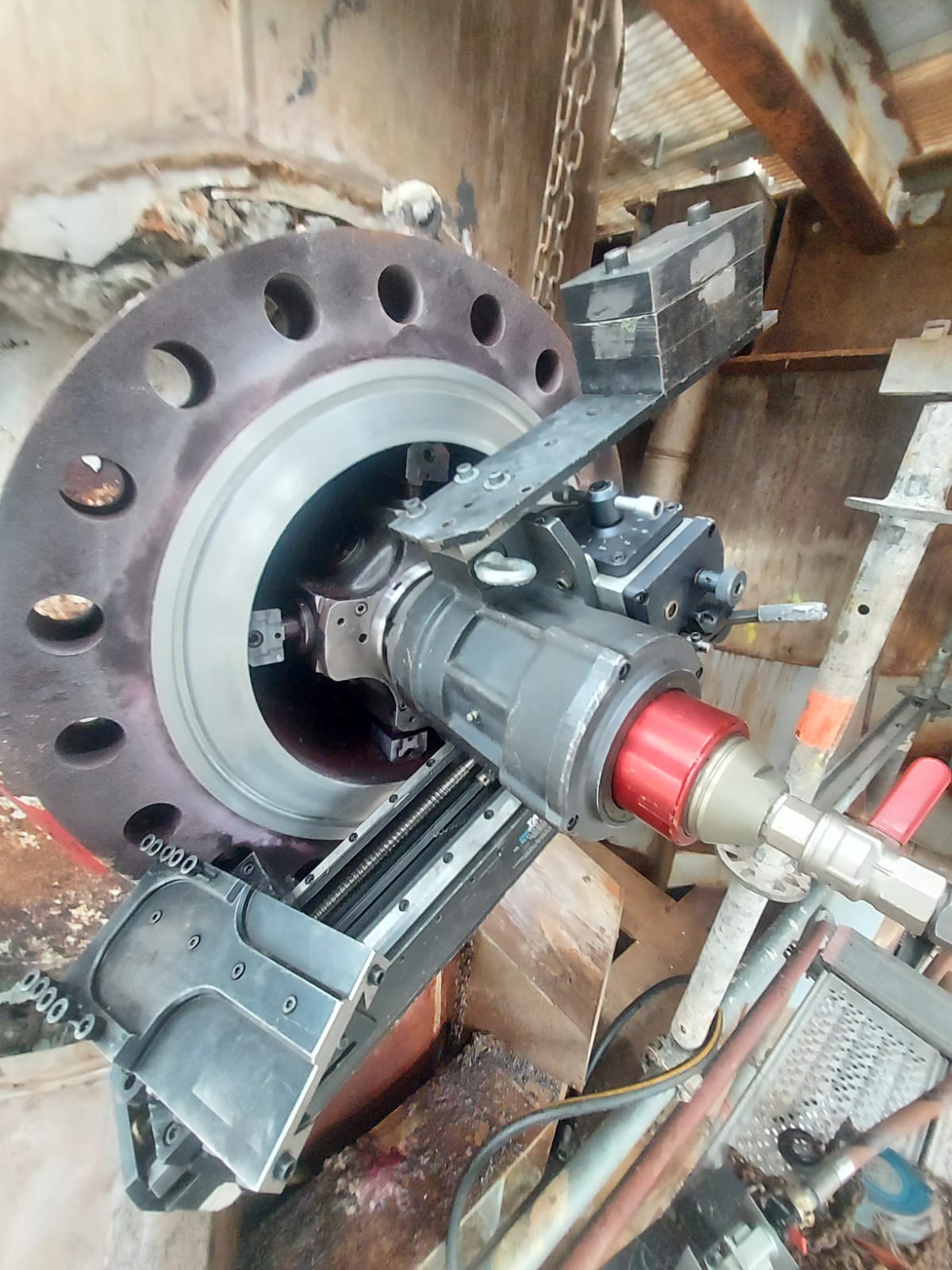

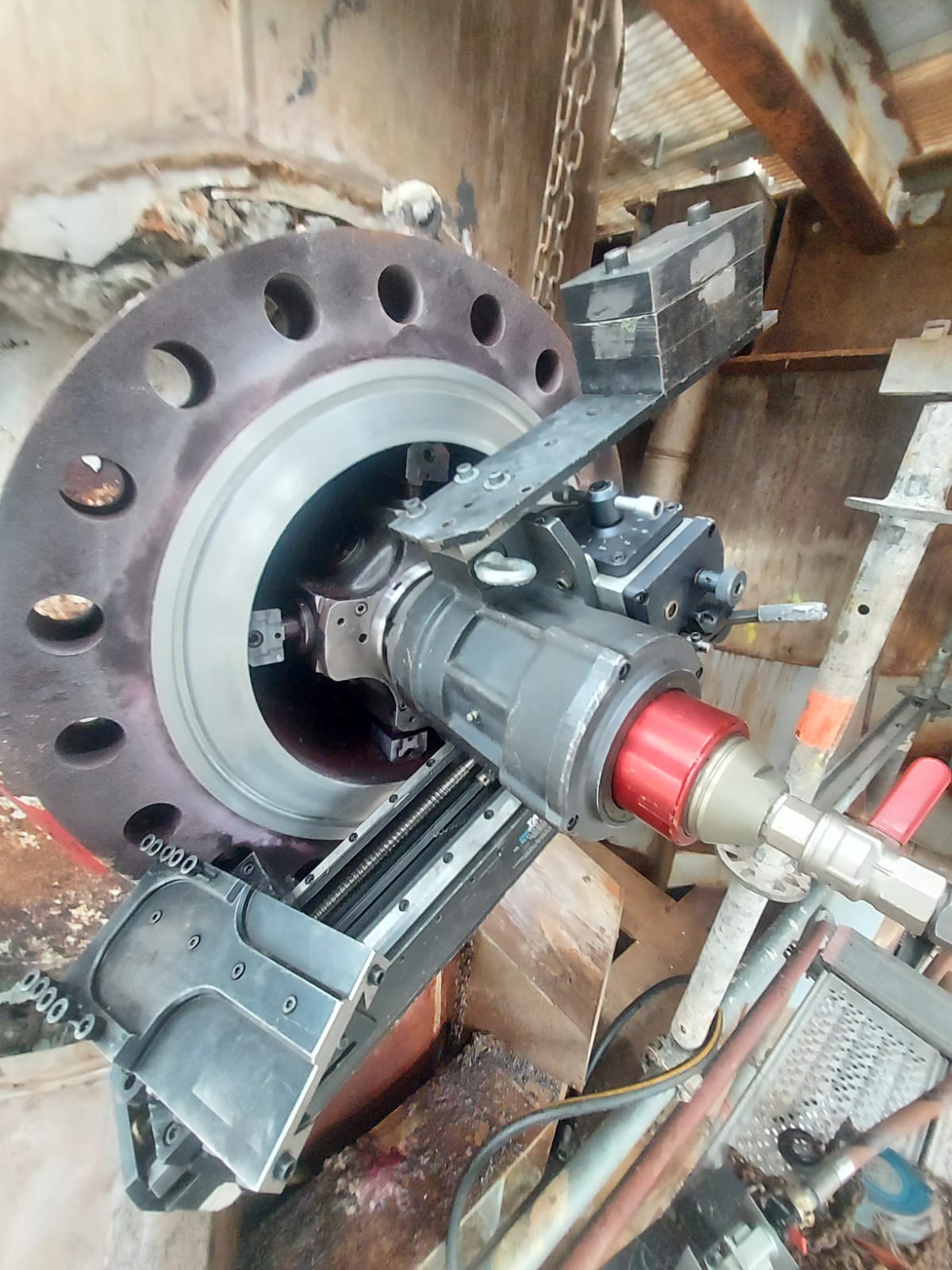

𝐑𝐞𝐩𝐚𝐢𝐫 𝐨𝐟 𝐚 Ø𝟐𝟎𝟎 𝐭𝐮𝐫𝐛𝐢𝐧𝐞 𝐬𝐡𝐚𝐟𝐭 𝐨𝐯𝐞𝐫 𝐚 𝐥𝐞𝐧𝐠𝐭𝐡 𝐨𝐟 𝟒𝟓𝟎𝐦𝐦

𝐷𝑢𝑒 𝑡𝑜 𝑎 𝑝𝑟𝑜𝑛𝑜𝑢𝑛𝑐𝑒𝑑 𝑤𝑒𝑎𝑟 𝑎𝑛𝑑 𝑡𝑒𝑎𝑟 𝑜𝑢𝑟 𝑐𝑢𝑠𝑡𝑜𝑚𝑒𝑟 𝑎𝑠𝑘𝑒𝑑 𝑢𝑠 𝑓𝑜𝑟 𝑎 𝑟𝑒𝑝𝑎𝑖𝑟 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛.

𝑊𝑒 𝑠𝑒𝑎𝑟𝑐ℎ𝑒𝑑 𝑡ℎ𝑒 𝑙𝑎𝑠𝑒𝑟 𝑡𝑟𝑎𝑐𝑘𝑒𝑟 𝐴𝑃𝐼 𝑀𝑒𝑡𝑟𝑜𝑙𝑜𝑔𝑦 𝑓𝑜𝑟 𝑡ℎ𝑒 𝑟𝑖𝑔ℎ𝑡 𝑟𝑒𝑓𝑒𝑟𝑒𝑛𝑐𝑒𝑠.

𝑂𝑢𝑟 𝑜𝑟𝑏𝑖𝑡𝑎𝑙 𝑚𝑎𝑐ℎ𝑖𝑛𝑒 𝑎𝑙𝑙𝑜𝑤𝑒𝑑 𝑢𝑠 𝑡𝑜 𝑑𝑒𝑙𝑎𝑟𝑑𝑒𝑟 10𝑚𝑚 𝑡𝑜 𝑡ℎ𝑒 𝑟𝑎𝑑𝑖𝑢𝑠 𝑤𝑖𝑡ℎ 𝑡𝑜𝑙𝑒𝑟𝑎𝑛𝑐𝑒𝑠 𝑖𝑛 𝑡ℎ𝑒 ℎ𝑢𝑛𝑑𝑟𝑒𝑑𝑡ℎ.

𝐹𝑜𝑙𝑙𝑜𝑤𝑖𝑛𝑔 𝑡ℎ𝑖𝑠 𝑚𝑎𝑐ℎ𝑖𝑛𝑖𝑛𝑔 𝑤𝑒 𝑚𝑎𝑑𝑒 ℎ𝑎𝑙𝑓 𝑠ℎ𝑒𝑙𝑙𝑠 𝑖𝑛 𝑜𝑢𝑟 𝑤𝑜𝑟𝑘𝑠ℎ𝑜𝑝𝑠 𝑎𝑛𝑑 𝑝𝑢𝑡 𝑡ℎ𝑒𝑚 𝑖𝑛 𝑝𝑙𝑎𝑐𝑒 𝑏𝑦 𝑤𝑒𝑙𝑑𝑖𝑛𝑔 𝑤𝑖𝑡ℎ 𝐸𝑑 𝑊𝑒𝑙𝑑𝑖𝑛𝑔 𝑓𝑜𝑟 𝑎 𝑝𝑒𝑟𝑓𝑒𝑐𝑡 𝑡𝑖𝑔ℎ𝑡𝑒𝑛𝑖𝑛𝑔 (𝑤𝑖𝑡ℎ𝑜𝑢𝑡 𝑤𝑒𝑙𝑑𝑖𝑛𝑔 𝑜𝑛 𝑡ℎ𝑒 𝑠ℎ𝑎𝑓𝑡).

𝐴𝑓𝑡𝑒𝑟 𝑤𝑒𝑙𝑑𝑖𝑛𝑔 𝑤𝑒 𝑚𝑎𝑐ℎ𝑖𝑛𝑒𝑑 𝑎𝑛𝑑 𝑔𝑟𝑜𝑢𝑛𝑑 𝑡𝑜 𝑝𝑢𝑡 𝑏𝑎𝑐𝑘 𝑎𝑙𝑙 𝑡ℎ𝑒 𝑑𝑖𝑚𝑒𝑛𝑠𝑖𝑜𝑛𝑠 𝑎𝑡 𝑡ℎ𝑒 𝑜𝑟𝑖𝑔𝑖𝑛 !!

𝐴𝑡 𝑡ℎ𝑒 𝑡𝑖𝑚𝑒 𝑜𝑓 𝑡𝑜𝑑𝑎𝑦 𝑡ℎ𝑒 𝑡𝑢𝑟𝑏𝑖𝑛𝑒 ℎ𝑎𝑠 𝑓𝑜𝑢𝑛𝑑 𝑎 𝑠𝑒𝑐𝑜𝑛𝑑 𝑦𝑜𝑢𝑡ℎ 𝑎𝑛𝑑 𝑖𝑡 𝑡𝑢𝑟𝑛𝑠 𝑝𝑒𝑟𝑓𝑒𝑐𝑡𝑙𝑦.

𝐴 𝑟𝑒𝑎𝑙 𝑝𝑙𝑒𝑎𝑠𝑢𝑟𝑒 𝑡𝑜 𝑤𝑜𝑟𝑘 𝑜𝑛 𝑗𝑒𝑤𝑒𝑙𝑠 𝑜𝑓 𝑡𝑒𝑐ℎ𝑛𝑜𝑙𝑜𝑔𝑦 𝑜𝑓 𝑡ℎ𝑒 𝑡𝑖𝑚𝑒.

𝑇ℎ𝑎𝑛𝑘 𝑦𝑜𝑢 𝑡𝑜 𝑜𝑢𝑟 𝑐𝑙𝑖𝑒𝑛𝑡 𝐸𝐷𝐹 𝑓𝑜𝑟 𝑡𝑟𝑢𝑠𝑡𝑖𝑛𝑔 𝑢𝑠 𝑓𝑜𝑟 𝑡ℎ𝑖𝑠 𝑠𝑒𝑟𝑣𝑖𝑐𝑒.

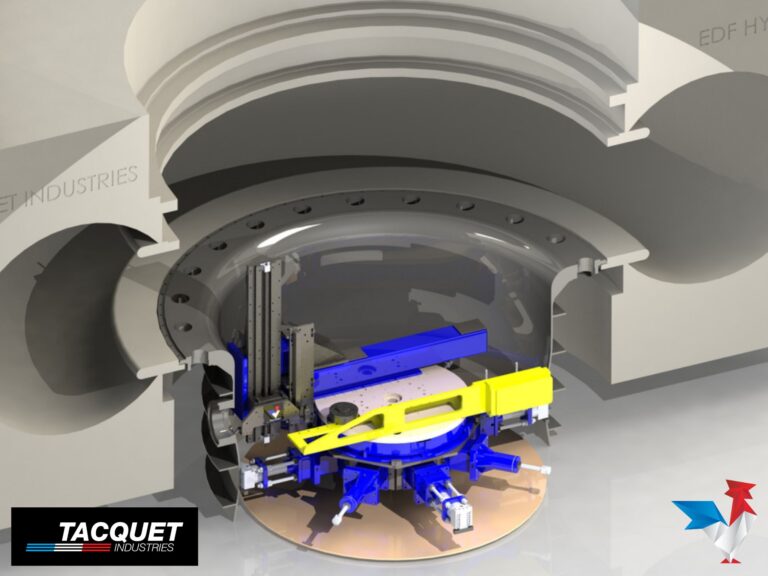

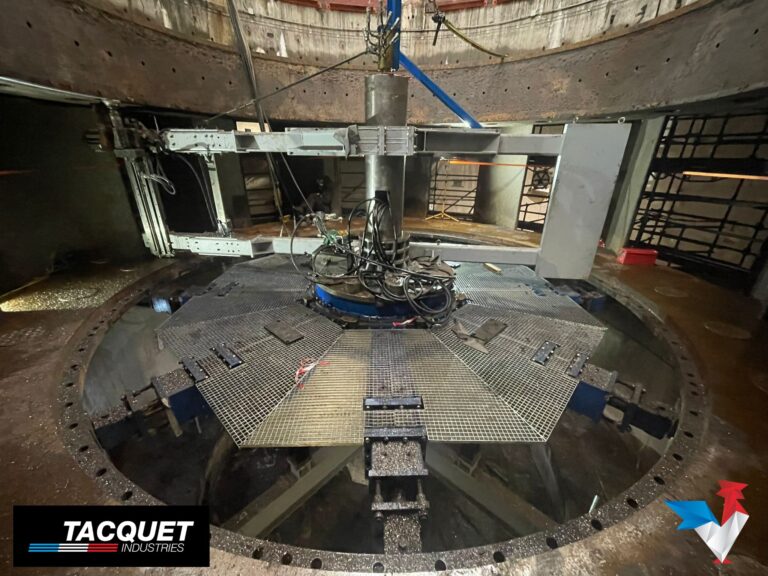

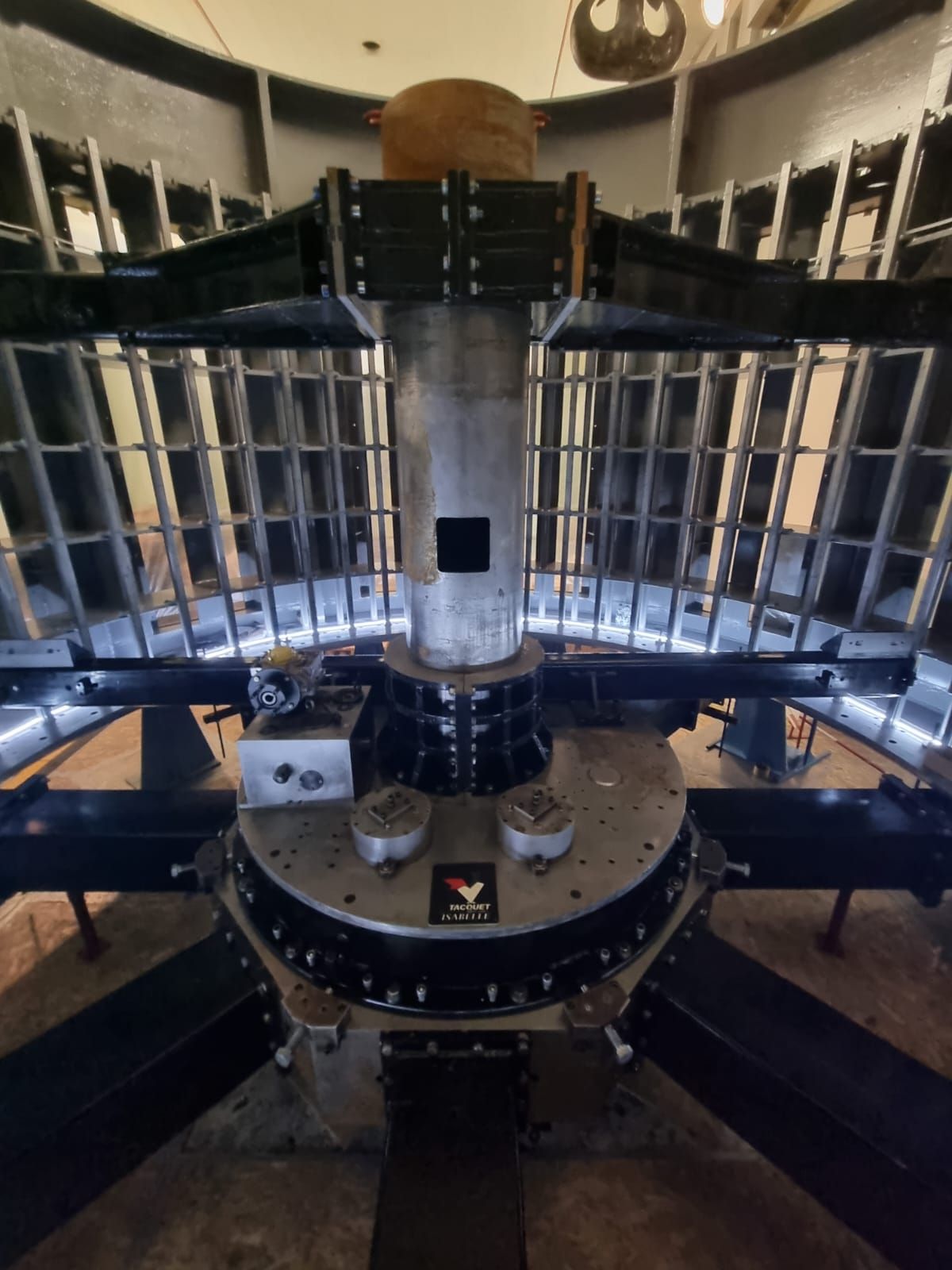

Double milling for ISABELLE

Published on 13/12/2023

𝑫𝒐𝒖𝒃𝒍𝒆 𝒎𝒊𝒍𝒍𝒊𝒏𝒈 𝒇𝒐𝒓 𝑰𝑺𝑨𝑩𝑬𝑳𝑳𝑬

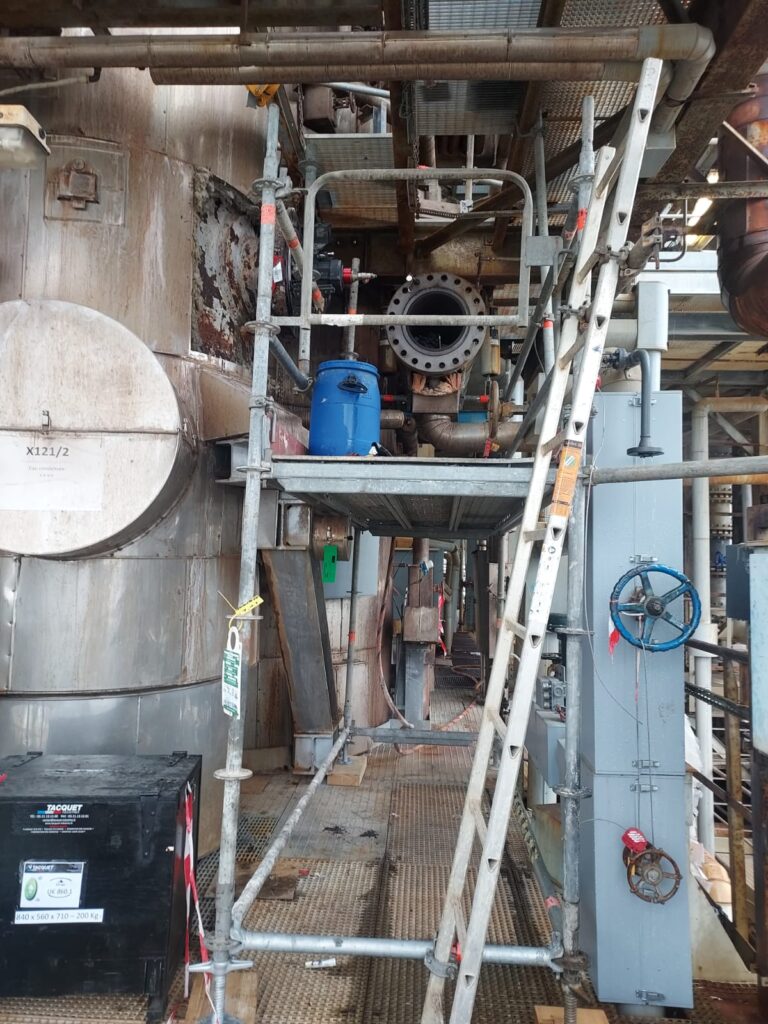

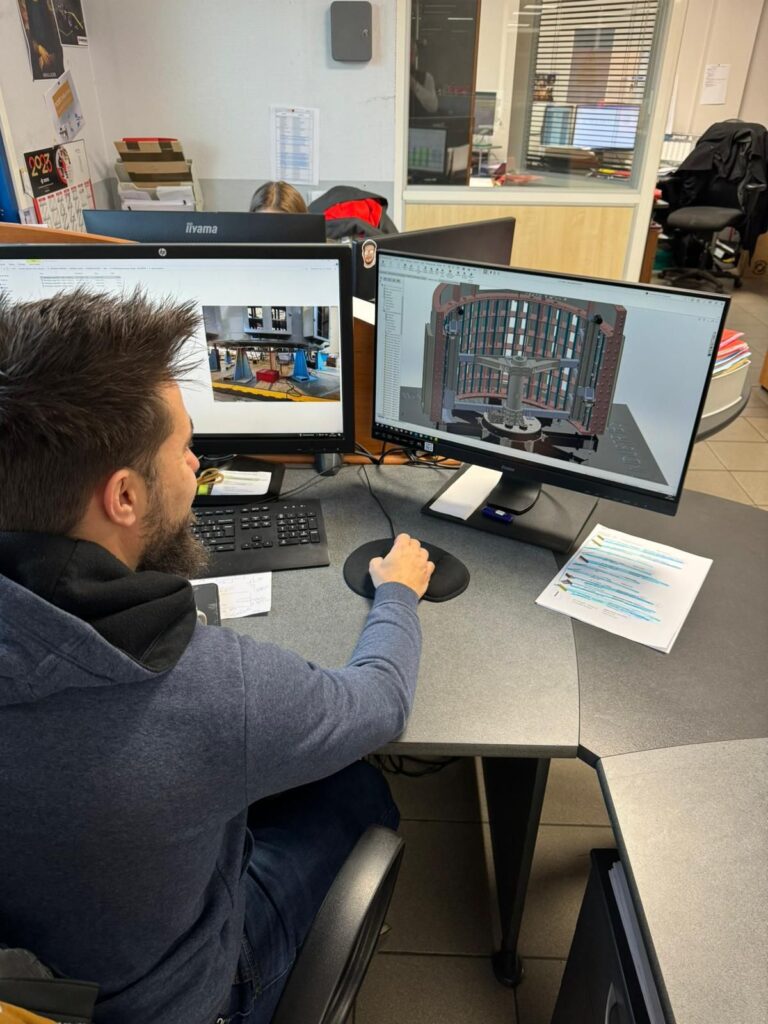

𝑇𝐴𝐶𝑄𝑈𝐸𝑇 𝐼𝑁𝐷𝑈𝑆𝑇𝑅𝐼𝐸𝑆 𝑖𝑠 𝑐𝑢𝑟𝑟𝑒𝑛𝑡𝑙𝑦 𝑜𝑛 𝑎 𝑠𝑡𝑎𝑡𝑜𝑟 𝑖𝑛 𝑎 ℎ𝑦𝑑𝑟𝑜 𝑝𝑙𝑎𝑛𝑡 𝑓𝑜𝑟 𝑚𝑎𝑐ℎ𝑖𝑛𝑖𝑛𝑔 𝑏𝑎𝑟𝑠 𝑜𝑛 3𝑚 ℎ𝑖𝑔ℎ 𝑥 50 !

𝑇ℎ𝑒 𝑚𝑎𝑐ℎ𝑖𝑛𝑒 𝑤𝑎𝑠 𝑠𝑒𝑡 𝑢𝑝 𝑤𝑖𝑡ℎ𝑜𝑢𝑡 𝑎𝑛𝑦 𝑝𝑟𝑜𝑏𝑙𝑒𝑚𝑠 𝑡ℎ𝑎𝑛𝑘𝑠 𝑡𝑜 𝑜𝑢𝑟 𝑖𝑚𝑝𝑙𝑎𝑛𝑡𝑎𝑡𝑖𝑜𝑛 𝑠𝑡𝑢𝑑𝑦.

𝑇ℎ𝑒 𝑎𝑑𝑗𝑢𝑠𝑡𝑚𝑒𝑛𝑡𝑠 𝑤𝑒𝑟𝑒 𝑚𝑎𝑑𝑒 𝑖𝑛 𝑡ℎ𝑒 0.20𝑚𝑚 𝑡𝑜 𝑡ℎ𝑒 𝑐𝑜𝑚𝑝𝑎𝑟𝑎𝑡𝑜𝑟 𝑜𝑛 𝑡ℎ𝑒 𝑜𝑟𝑖𝑔𝑖𝑛, 𝑎𝑛𝑑 𝑤𝑒 𝑓𝑖𝑛𝑖𝑠ℎ𝑒𝑑 𝑤𝑖𝑡ℎ 𝑜𝑢𝑟 𝑐𝑢𝑠𝑡𝑜𝑚𝑒𝑟 𝑡ℎ𝑒 𝑙𝑎𝑠𝑒𝑟 𝑡𝑟𝑎𝑐𝑘𝑒𝑟 𝑠𝑒𝑡𝑡𝑖𝑛𝑔𝑠 𝑓𝑜𝑟 𝑐𝑜𝑛𝑐𝑒𝑛𝑡𝑟𝑖𝑐𝑖𝑡𝑦 𝑎𝑛𝑑 𝑝𝑎𝑟𝑎𝑙𝑙𝑒𝑙𝑖𝑠𝑚 𝑡𝑜 𝑡ℎ𝑒 𝑐𝑦𝑙𝑖𝑛𝑑𝑒𝑟 𝑖𝑛 𝑡ℎ𝑒 𝑡𝑒𝑛𝑡ℎ.

𝐶𝑢𝑟𝑟𝑒𝑛𝑡𝑙𝑦 𝑚𝑖𝑙𝑙𝑖𝑛𝑔 𝑖𝑠 𝑢𝑛𝑑𝑒𝑟𝑤𝑎𝑦, 𝑏𝑢𝑡 𝑙𝑒𝑡’𝑠 𝑘𝑒𝑒𝑝 𝑎 𝑔𝑟𝑒𝑎𝑡 𝑣𝑖𝑑𝑒𝑜 𝑓𝑜𝑟 𝑎 𝑓𝑢𝑡𝑢𝑟𝑒 𝑝𝑜𝑠𝑡

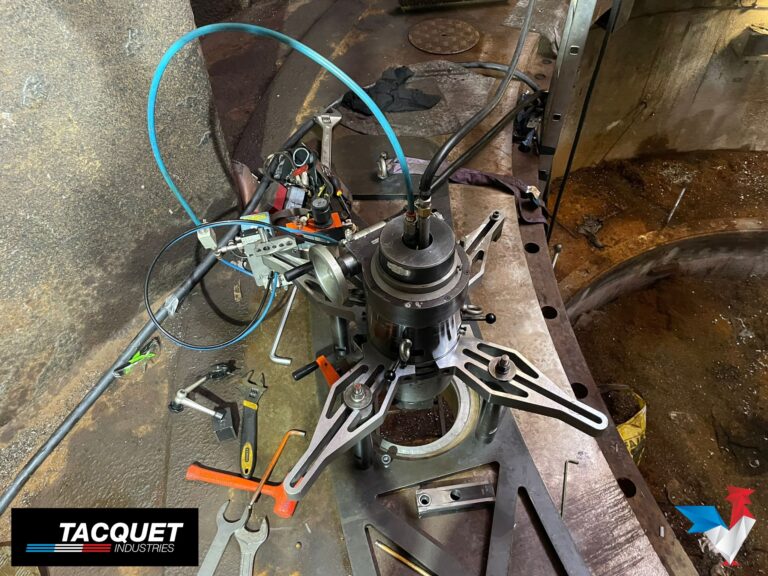

Site preparation

Published on 04/12/2023

𝑺𝒊𝒕𝒆 𝒑𝒓𝒆𝒑𝒂𝒓𝒂𝒕𝒊𝒐𝒏 🚧

𝘉𝘦𝘩𝘪𝘯𝘥 𝘵𝘩𝘦 𝘴𝘤𝘦𝘯𝘦𝘴 𝘱𝘳𝘦𝘱𝘢𝘳𝘢𝘵𝘪𝘰𝘯𝘴 𝘰𝘧 𝘰𝘶𝘳 𝘵𝘸𝘰 𝘭𝘢𝘳𝘨𝘦𝘴𝘵 𝘮𝘢𝘤𝘩𝘪𝘯𝘪𝘯𝘨 𝘮𝘢𝘤𝘩𝘪𝘯𝘦𝘴 𝘰𝘯 𝘴𝘪𝘵𝘦

𝘈 𝘴𝘮𝘢𝘭𝘭 𝘸𝘪𝘯𝘬 𝘧𝘰𝘳 𝘐𝘴𝘢𝘣𝘦𝘭𝘭𝘦 𝘸𝘩𝘰 𝘳𝘦𝘴𝘶𝘮𝘦𝘴 𝘴𝘦𝘳𝘷𝘪𝘤𝘦

Wheel coat Ø3400

Published on 29/08/2023

Wheel coat Ø3400

Take a wheel coat Ø3400 of a Kaplan turbine by machining and all that on site?! The TACQUET INDUSTRIES teams also know how to do it!

If you want to know more, it’s here 👇

During the month of July, our teams had the privilege of working on the renovation of another hydroelectric power plant group. ♻️💧

THE MISSION: 🔍

– Resumption of the cylindrical and spherical part Ø3400 of the wheel mantle on a height of 1m.

Tolerances requested: 🔑

– Final coast of cylinder diameter and sphere Ø3400

– Surface condition: Ra 3.2 max

Machine used: Boring-Surfacer TI6500 🎯

The subtlety on this site lies in the development of a completely mechanical copier to follow and recreate the original shape of the coat. No CNC was used for this operation. 👌

Intervening on this type of site allows us to improve our techniques in order to deliver an optimal quality of service and services for our customers!

VERDICT: 🏆Successful mission🏆

This new success was achieved thanks to rigorous preparation upstream by our Design Office and the professionalism of our technicians on site. 💯

We thank Automated Precision Europe GmbH for their support on this project.

We also thank our client EDF for its confidence in this project and especially Pol Piedfer and Loic Potel for the organization of the site. 🤝

Machining of flanges Ø8700

Published on 07/08/2023

Flanges machining Ø8700

Can I machine Ø8700 flanges on site?

Want to know more about the last titanic project recently completed by TACQUET INDUSTRIES teams? Continue reading we will tell you everything.

In recent months we had the pleasure of working on the complete renovation of unit 1 of the EDF hydroelectric power station in Ottmarsheim for our customer Voith Hydro. ♻️💧

THE MISSION: 🔍

– Machining flange and Ø6050 H7 foundation ring

– Surfacing of the upper face of the inf ring (Ø6900 to Ø8700) then machining of the face and diameter Ø6900

– Surfacing of the inf face of the head cover (Ø6900 to Ø8700)

– Addition of modifications to the 48 Sealing Guide Pots (Drilling/Tapping, Countermeasures)

Tolerances requested: 🔑

– Horizontality and flatness of machined planes: 0.02mm/m

– Surface Condition: Ra 6.3

– Deck depth: 0.1mm

– Bores: H7

Machines used: TI8500 Boring Machine/ TU400 Boring Machine/ MAB485 Magnetic Drill 🎯

On this site, for its maximum surfacing configuration our machine TI8500 reaches 10m diameter for a mass of almost 20T 🤯

VERDICT: 🏆Successful mission🏆

This new challenge was won thanks to the preparation work carried out by our Design Office as well as the quality of work and the investment of our technicians on site. 💯

We thank Automated Precision Europe GmbH for their involvement in this project.

We also thank our client Voith Hydro for his professionalism and confidence in this project and especially Julien Lacroix, Etienne Pernot and Julia Heinisch for the organization of the site. 🤝