8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

DRILLING & TAPPING

On site drilling and tapping

Fast and accurate machining without disassembly

At TACQUET INDUSTRIES, we carry out on-site drilling operations directly on your fixed or mobile equipment. This technique involves creating perfectly positioned holes without needing to move or dismantle the parts. It is ideal for working on large or welded structures with accuracy and efficiency.

Thanks to our expertise and a fleet of over 200 portable machines, we operate in a wide range of conditions, including the most demanding ones.

We ensure perfect alignment, controlled depth, and industrial-grade finishing that meets the most stringent standards.

On-site tapping allows us to create or restore threads on existing parts without any disassembly or transportation.

This operation is essential for ensuring the mechanical integrity of a bolted assembly, with strict compliance to pitch, diameter, and depth specifications.

The flexibility of our equipment combined with the expertise of our technicians ensures a clean, reliable, and compliant thread — even in demanding materials such as stainless steel or special alloys.

When to perform a drilling or tapping on site?

This technique is particularly well-suited when:

Dismantling the equipment would be complex or costly

A threaded hole needs to be added or an existing fixture reworked

Welded or assembled structures require precision intervention

The working environment is tight or access is restricted

Drilling must be integrated into a broader machining operation (milling, boring, etc.)

Our teams regularly perform these operations in demanding sectors such as energy, marine, chemical, steel, hydraulic, and rail industries.

Technical means

Our teams use magnetic, portable, column-mounted, or jig-based drills, specifically adapted to field constraints.

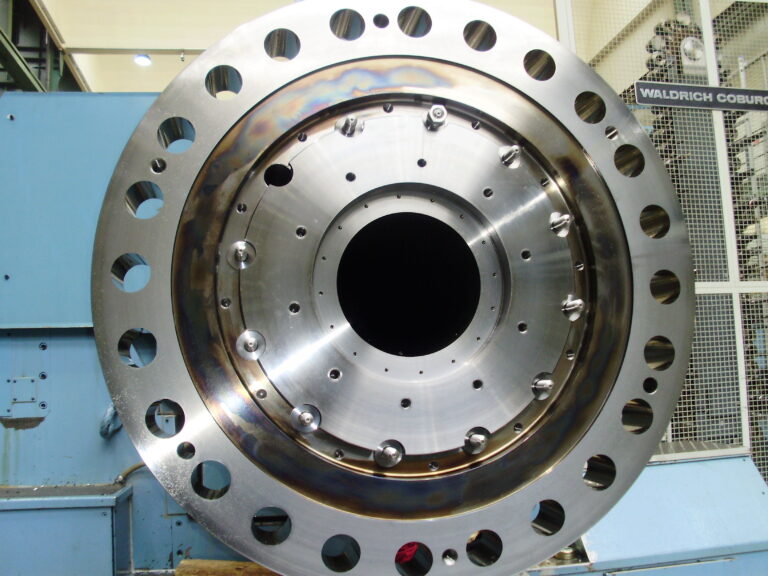

We specialize in high-precision drilling, up to several hundred millimeters in diameter, as well as metric or custom-thread tapping, including in complex materials such as steel, stainless steel, or special alloys.

Each operation is carefully prepared in advance through dimensional checks, laser positioning if required, and validation of the appropriate tooling — including lubrication, drilling depth, threading parameters, and torque.

Your advantages

✅ No disassembly required

✅ Time-saving and reduced production downtime

✅ Compliant with drilling and threading standards

✅ Fully adaptable to site constraints

✅ Can be integrated into a broader on-site machining operation

DRILLING

Drilling is the process of creating a hole in a material using a drill or a drilling tool. This technique is essential for many industrial applications, whether it be the drilling of holes for screws, shafts or cable passages.

At TACQUET INDUSTRIES, we provide our expertise to perform precise drilling and adapted to the specificities of each project, guaranteeing a fast and quality execution on site.

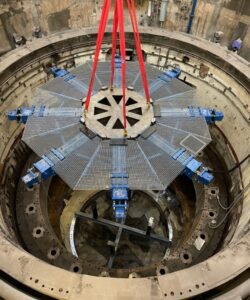

ACHIEVEMENTS

For any request for quotation or to discuss your project of machining on site, do not hesitate to contact us. Our team is at your disposal to advise you and offer the most appropriate services to your expectations. We will be happy to support you in the success of your machining projects.