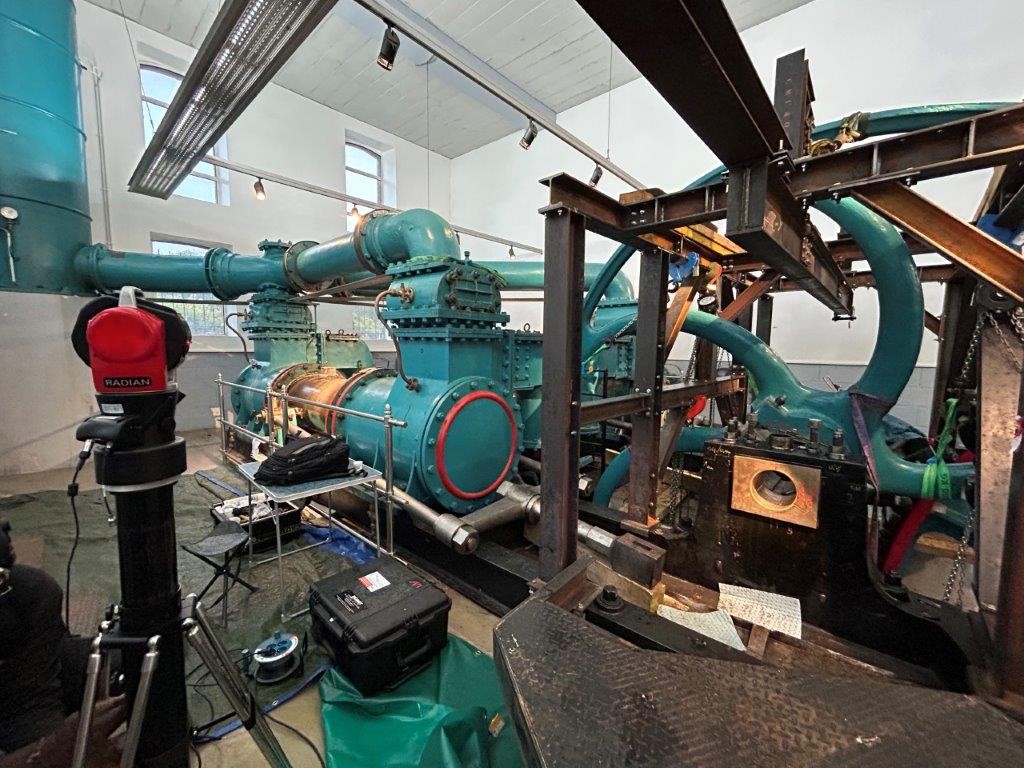

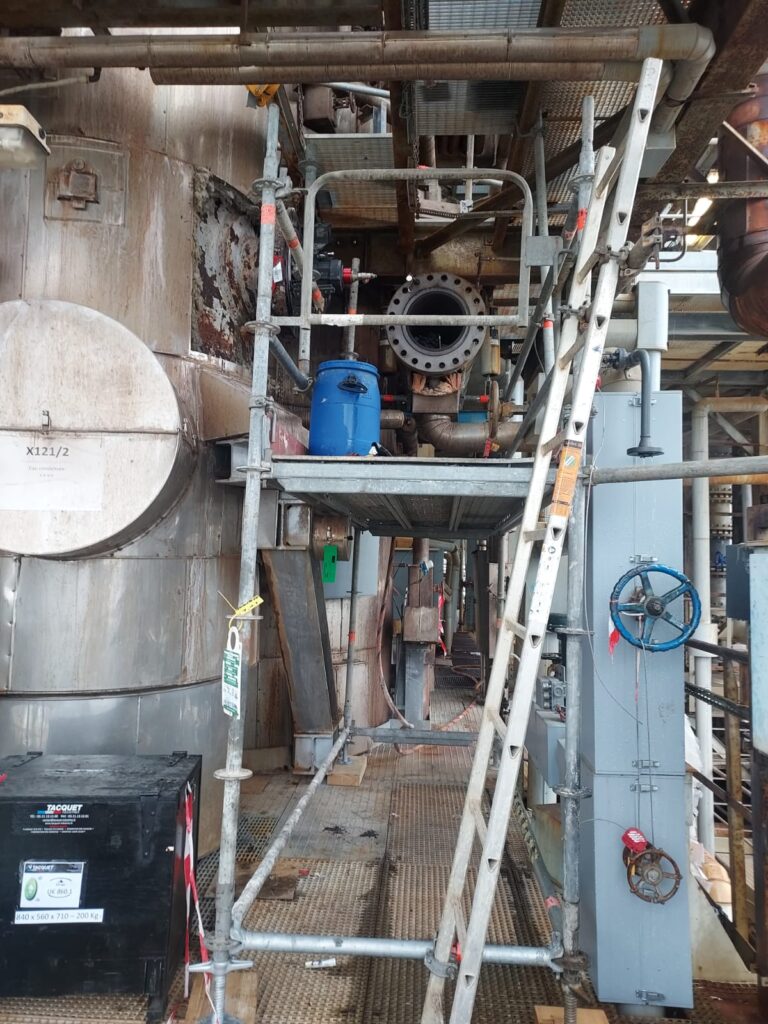

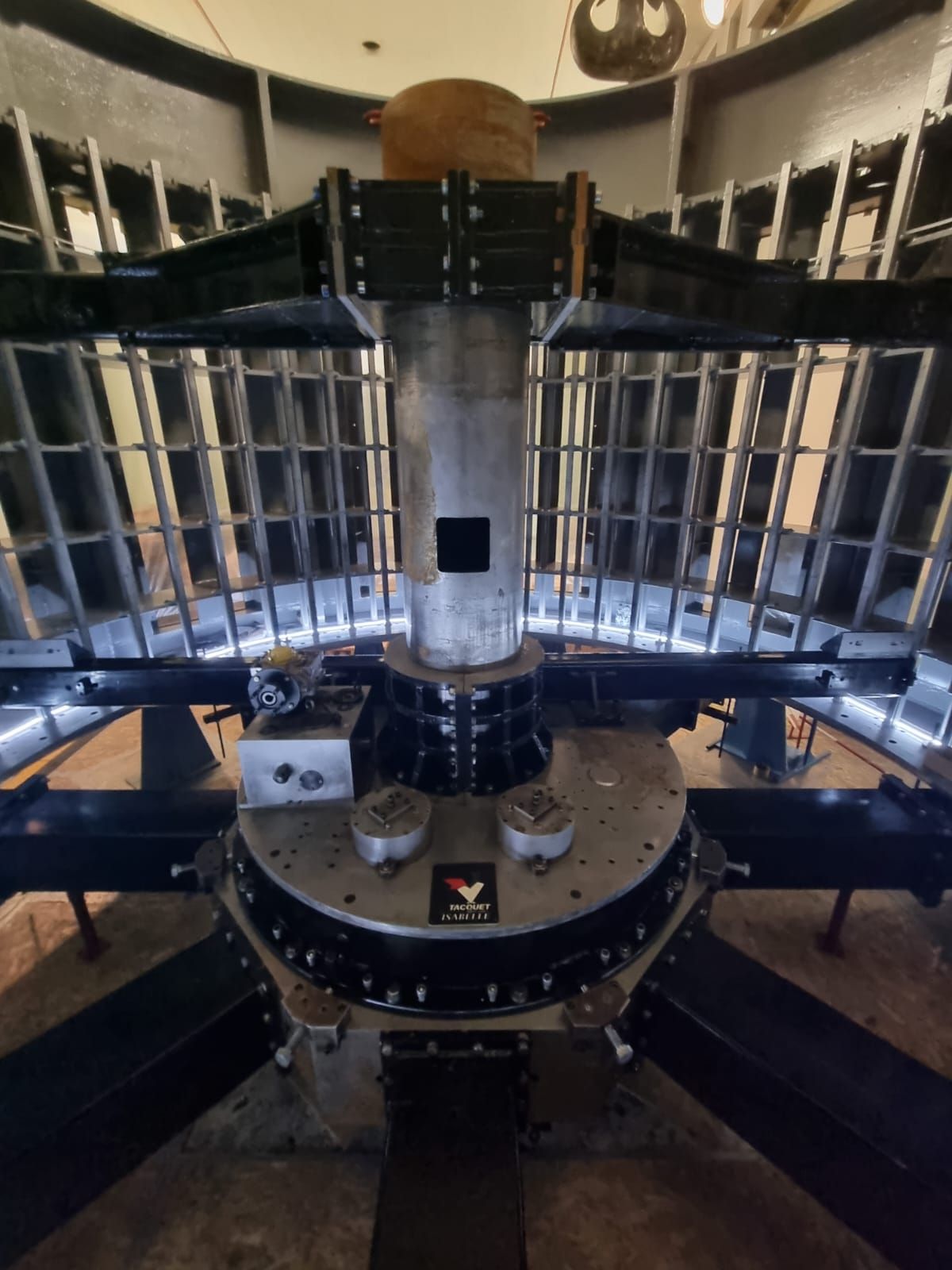

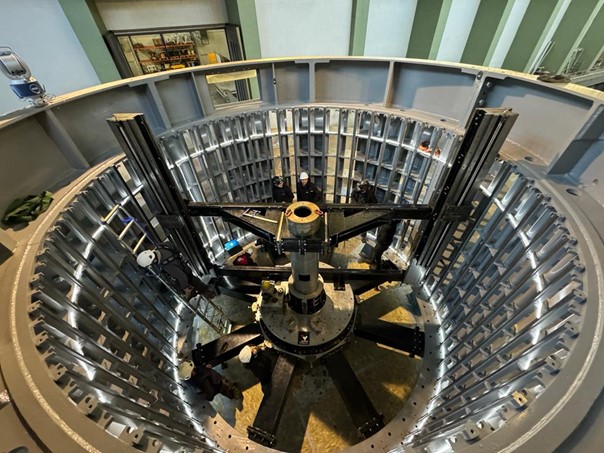

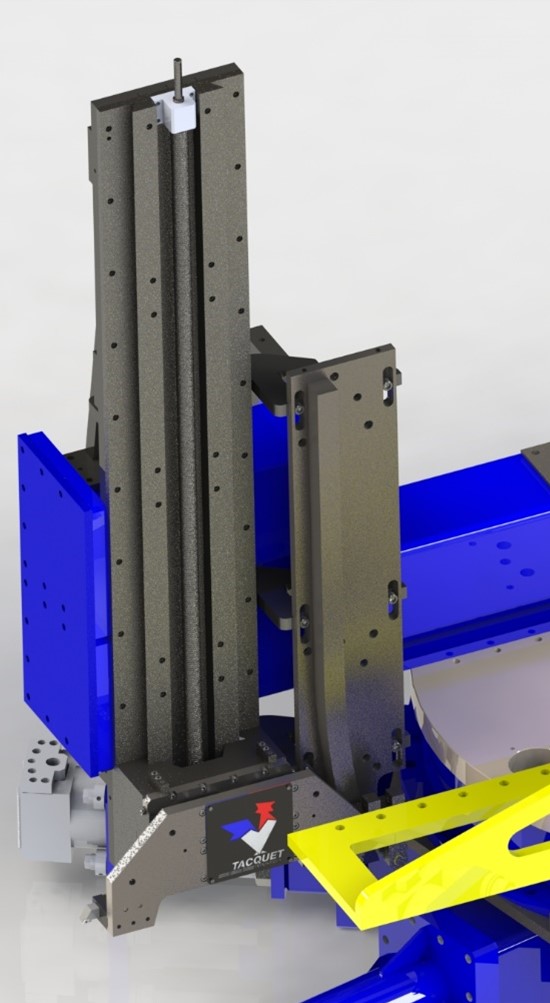

Measure line of fire

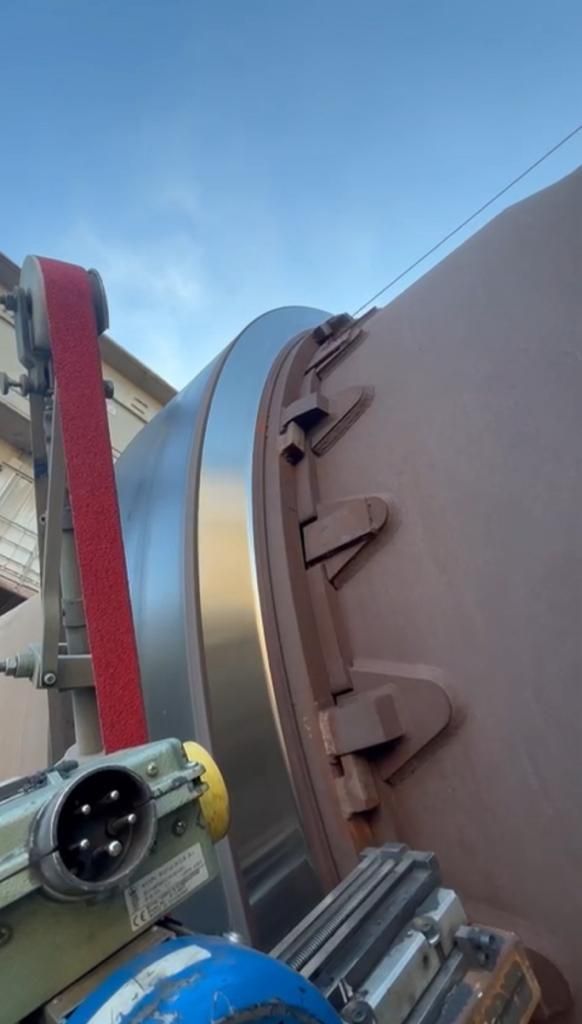

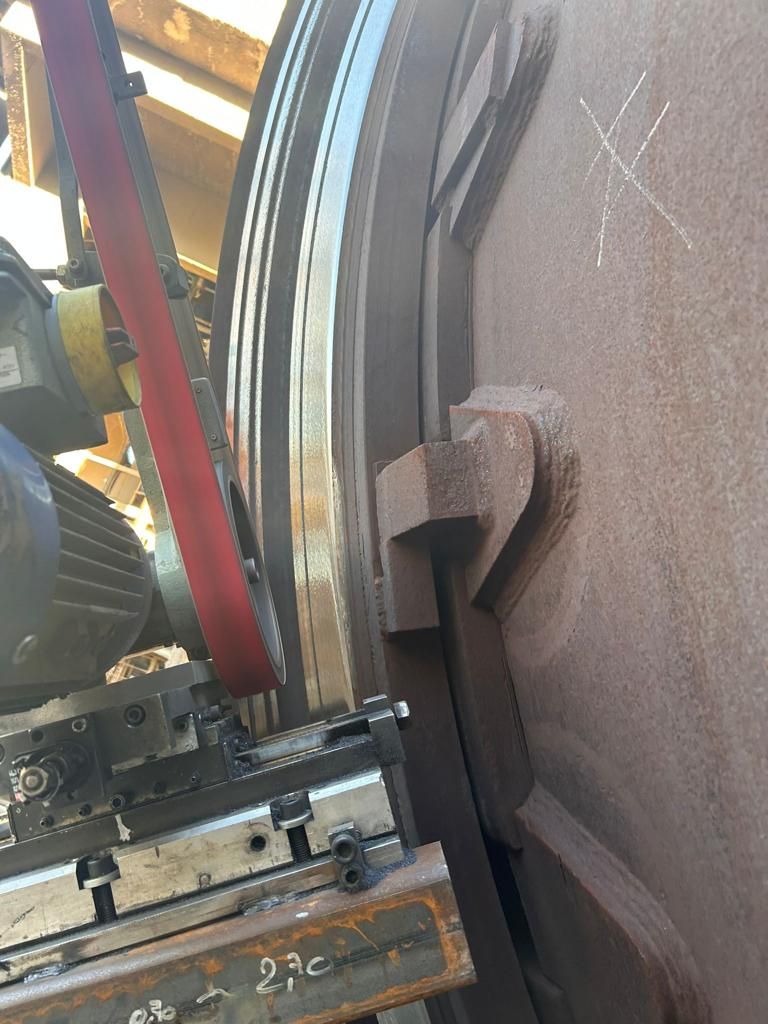

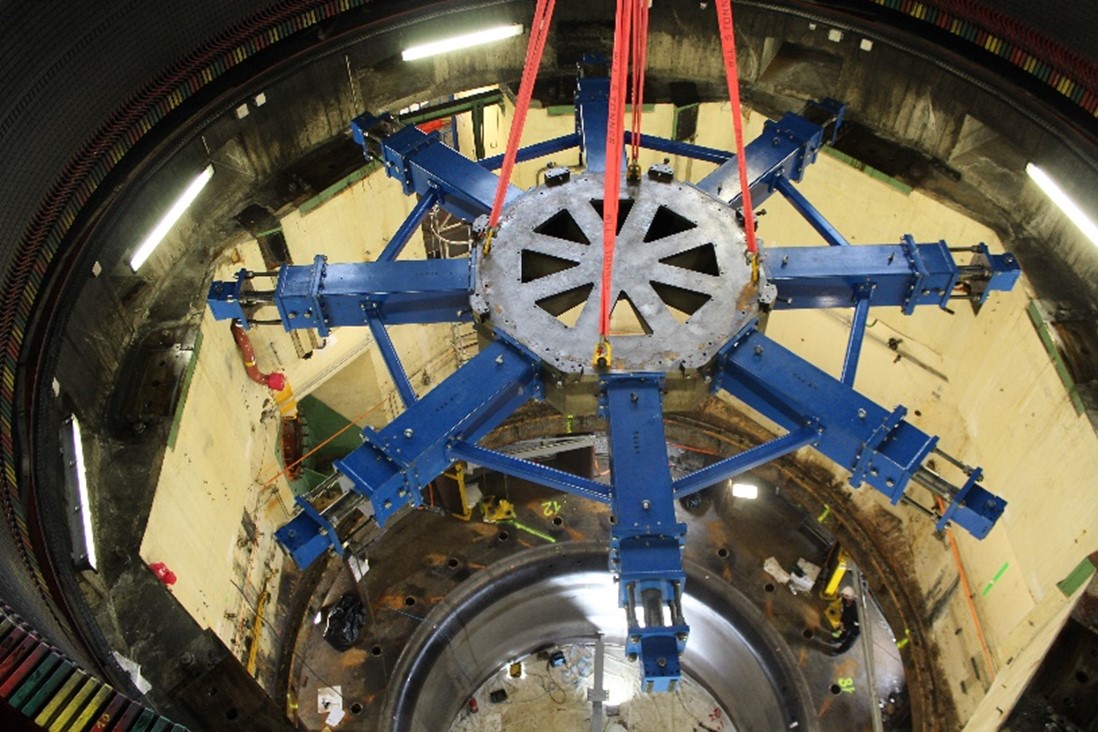

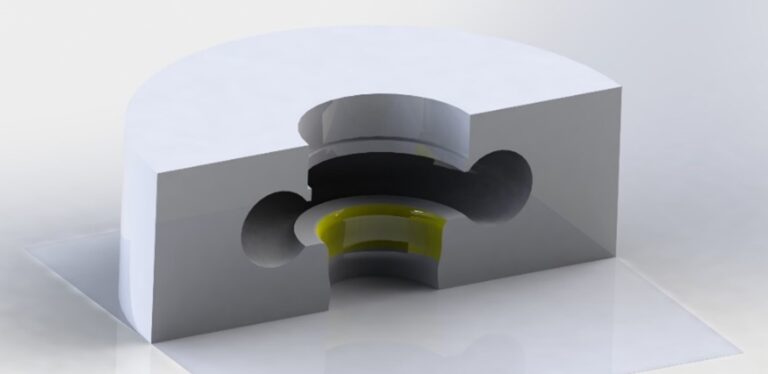

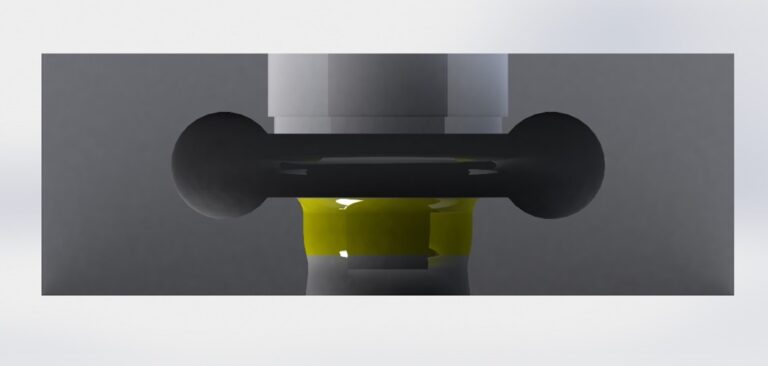

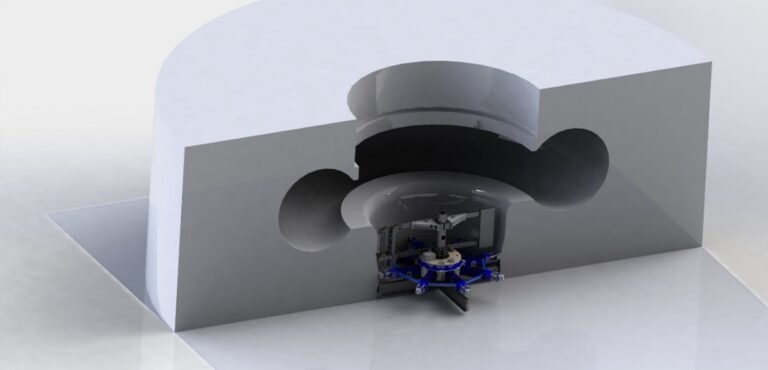

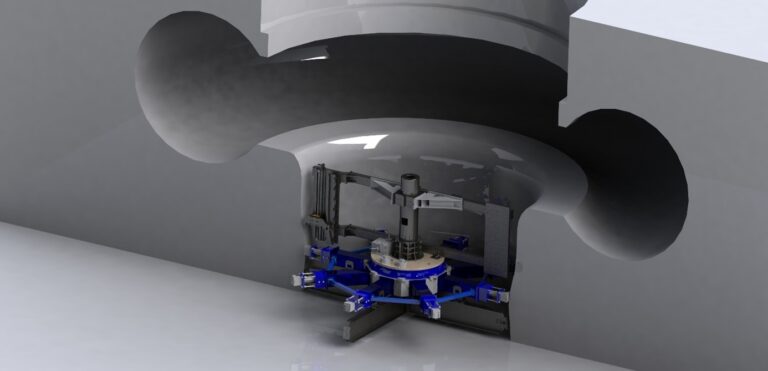

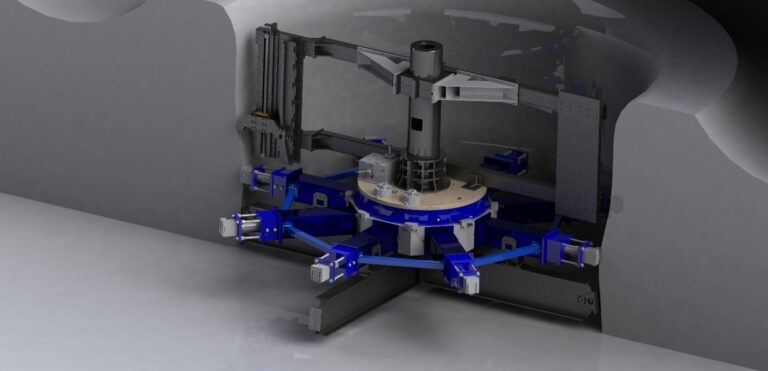

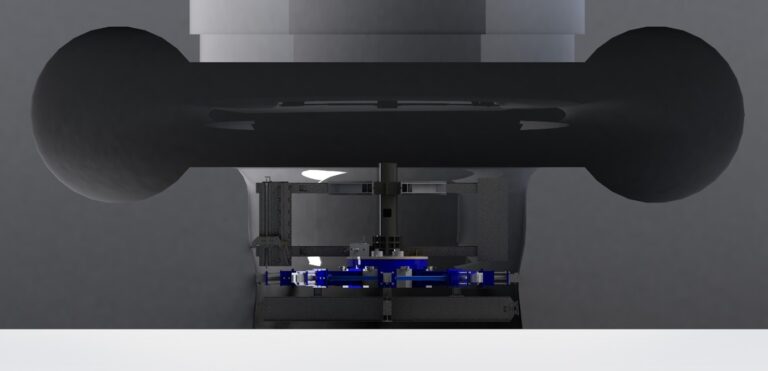

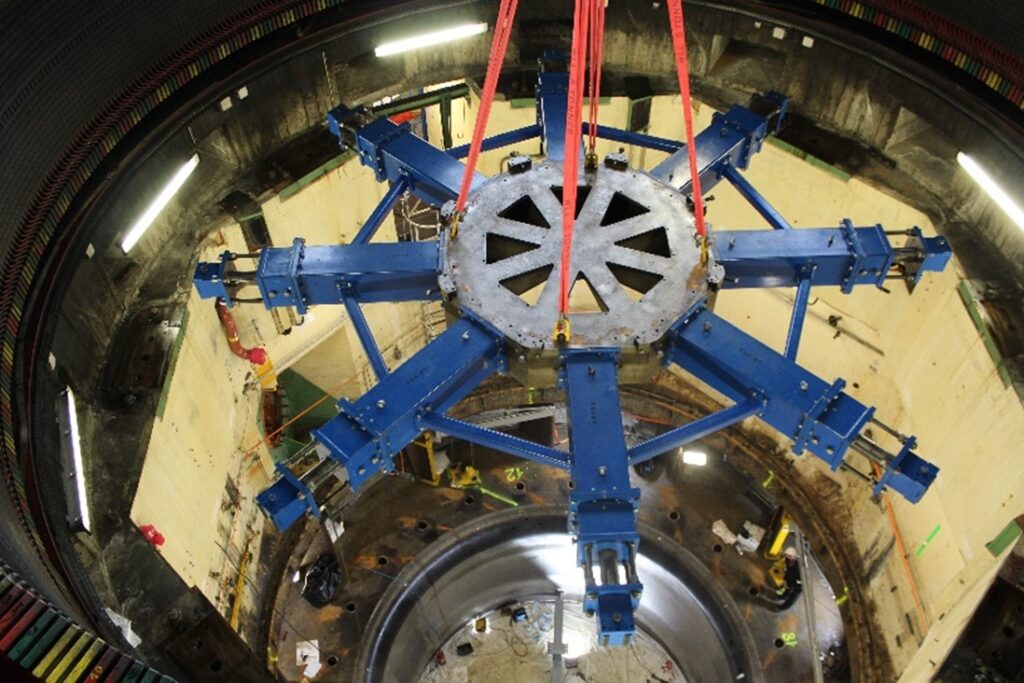

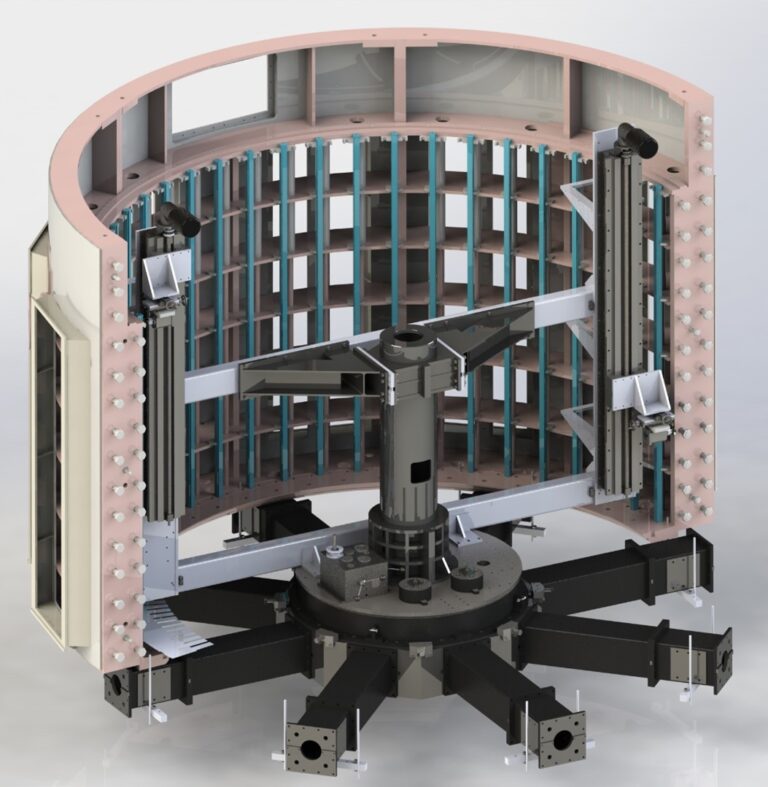

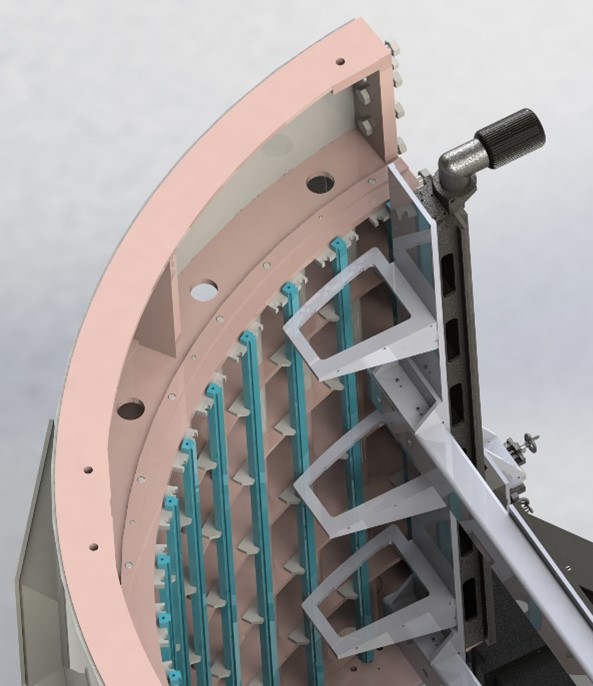

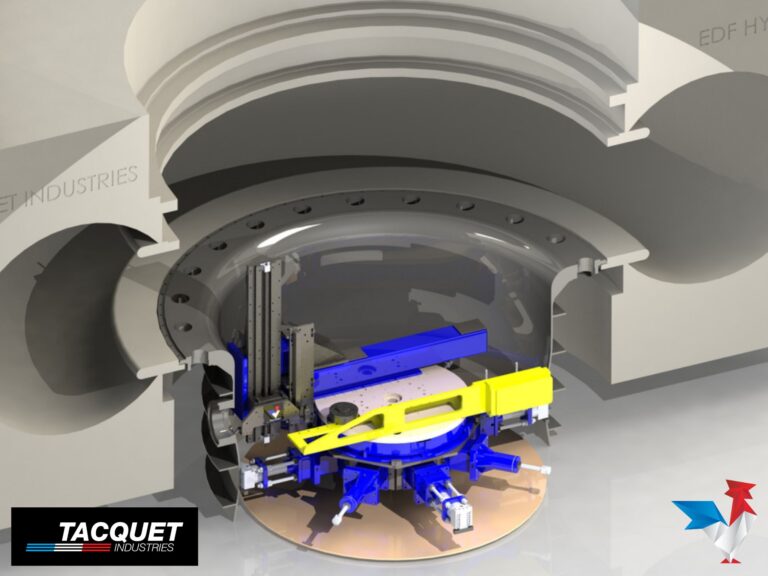

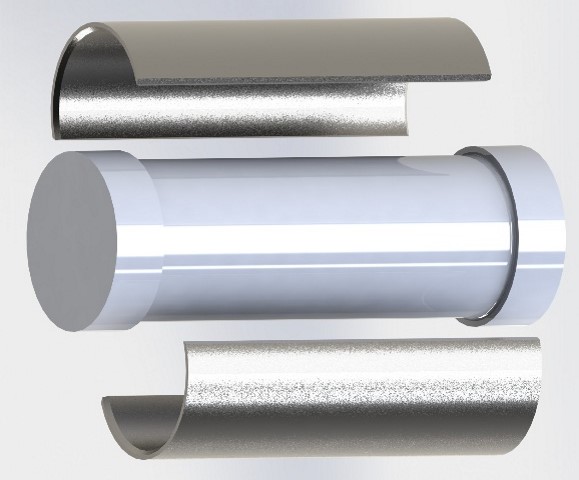

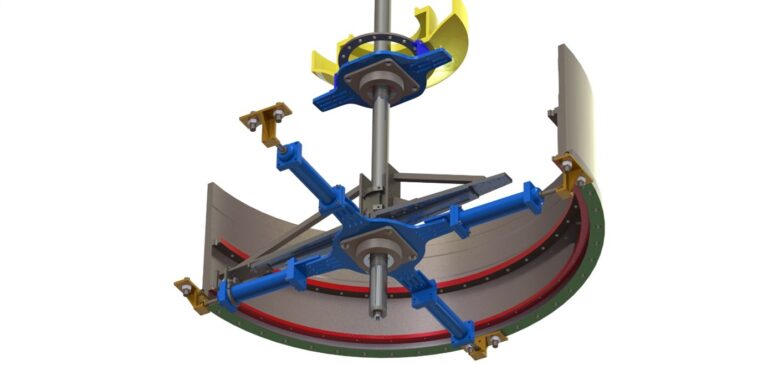

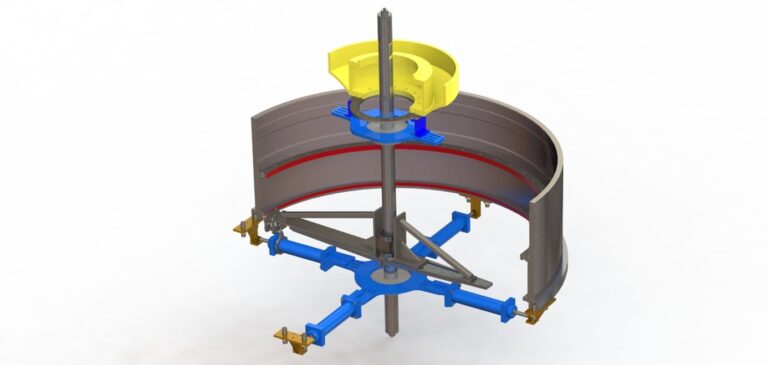

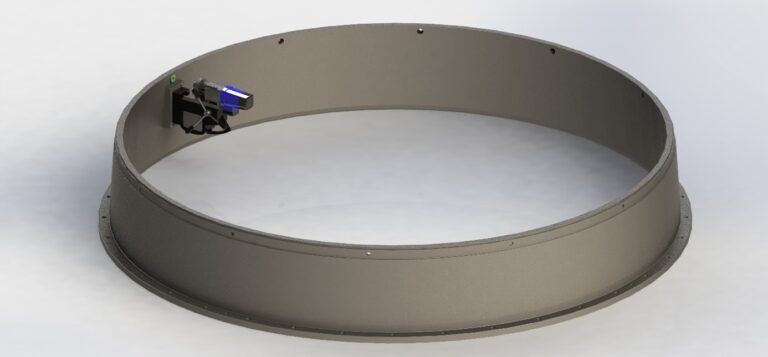

Alignment Check of the Shaft Line

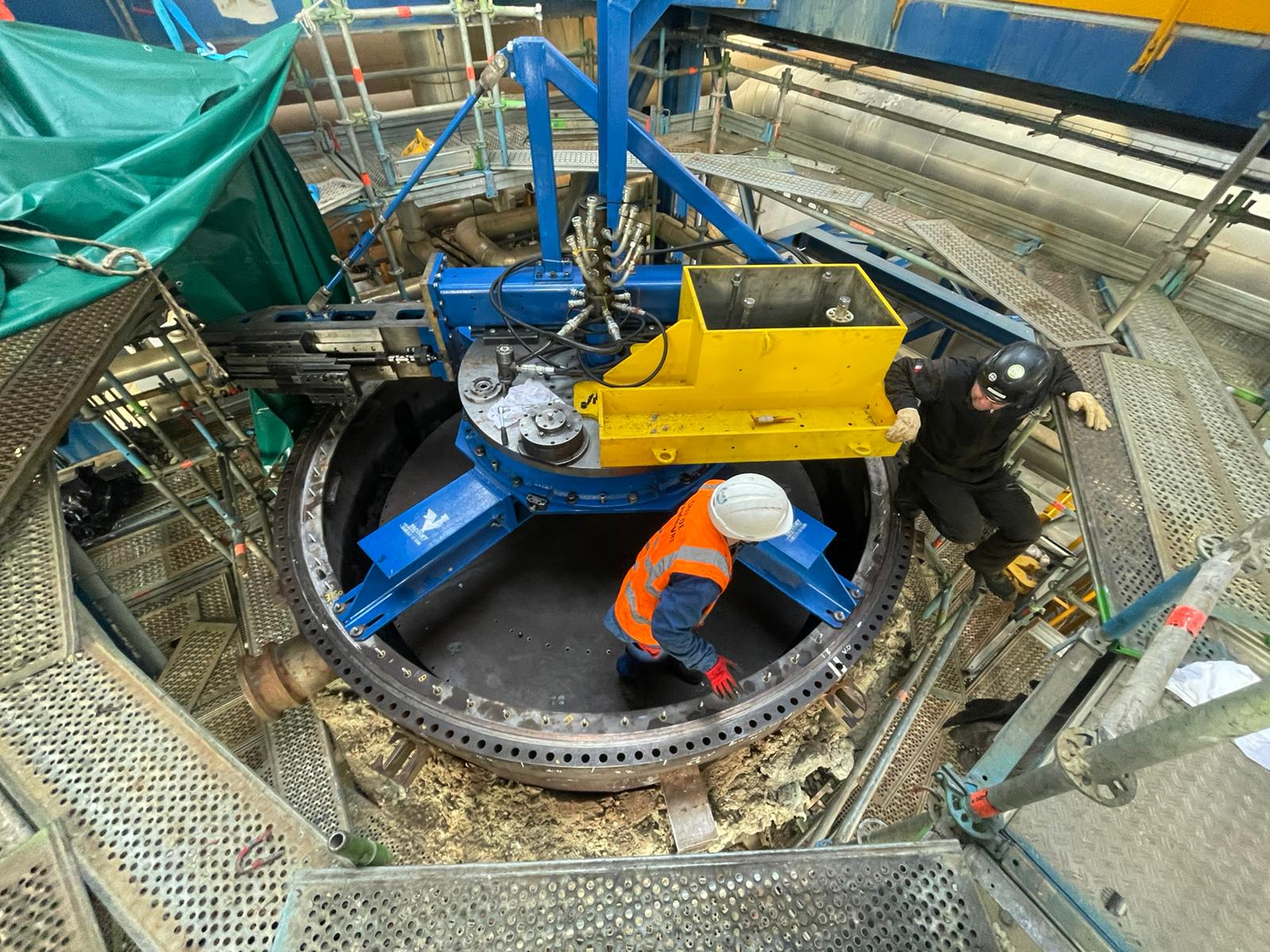

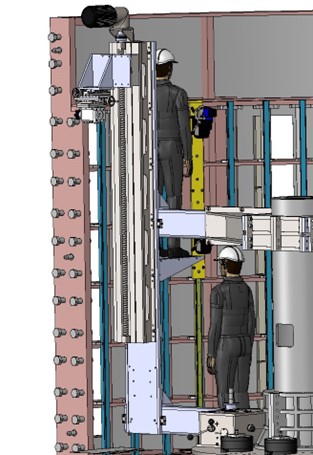

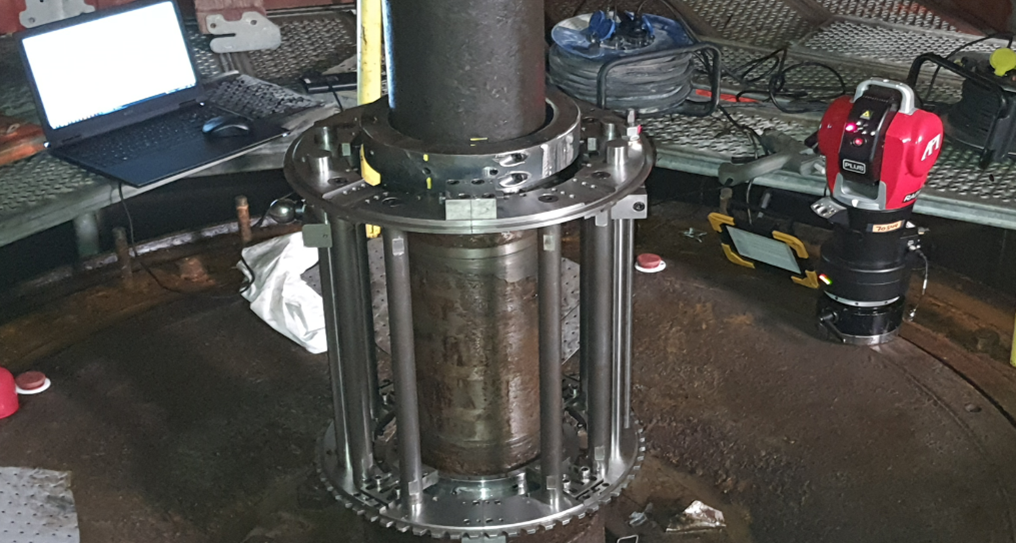

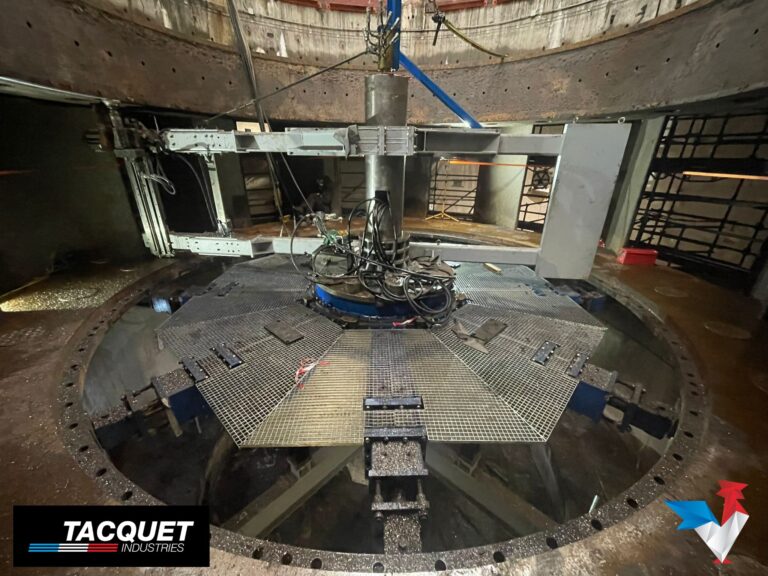

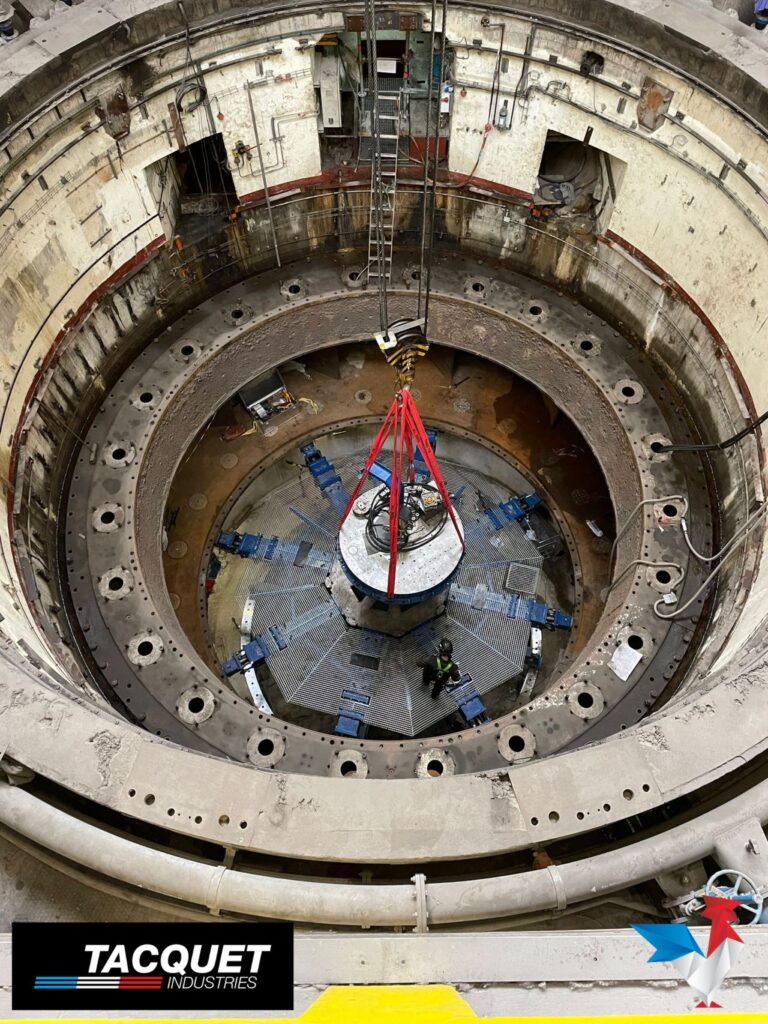

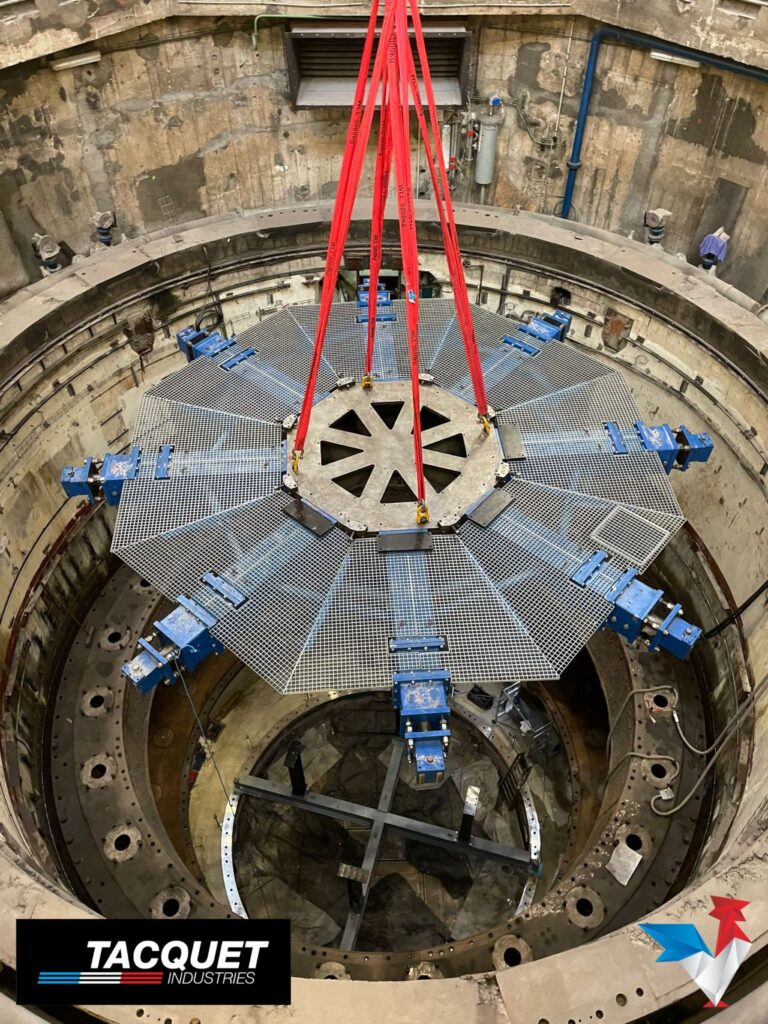

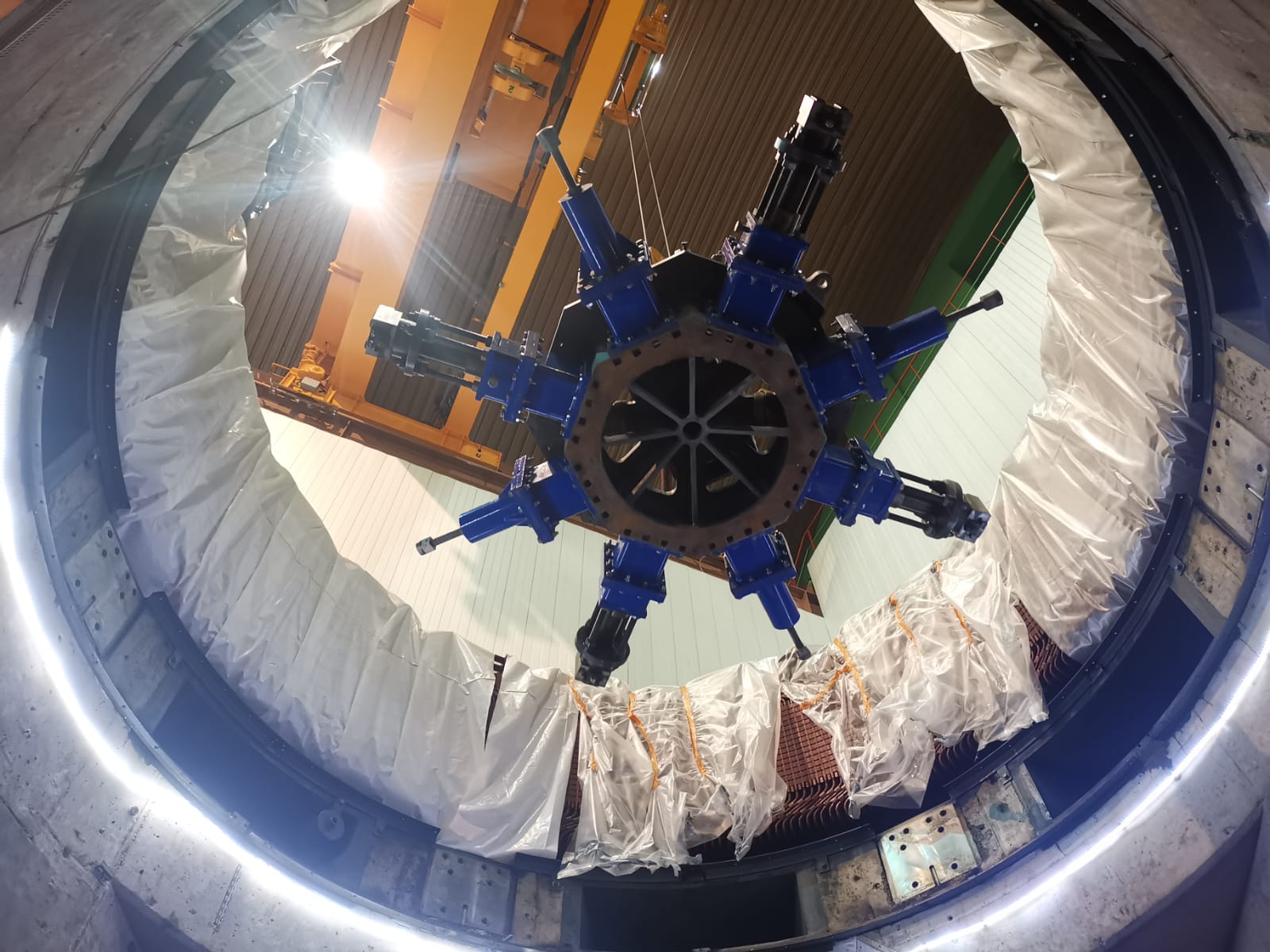

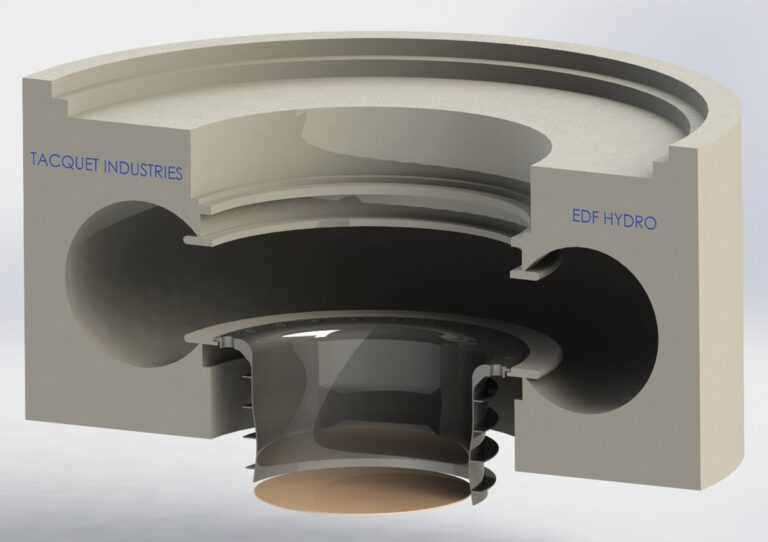

A metrological inspection was carried out on the shaft line of the sailing yacht S/Y Naema, following the replacement of the thrust bearing silent blocks. Conducted at the Monaco Marine site, the purpose of the intervention was to verify the mechanical alignment between the drivetrain components as part of a post-maintenance adjustment.

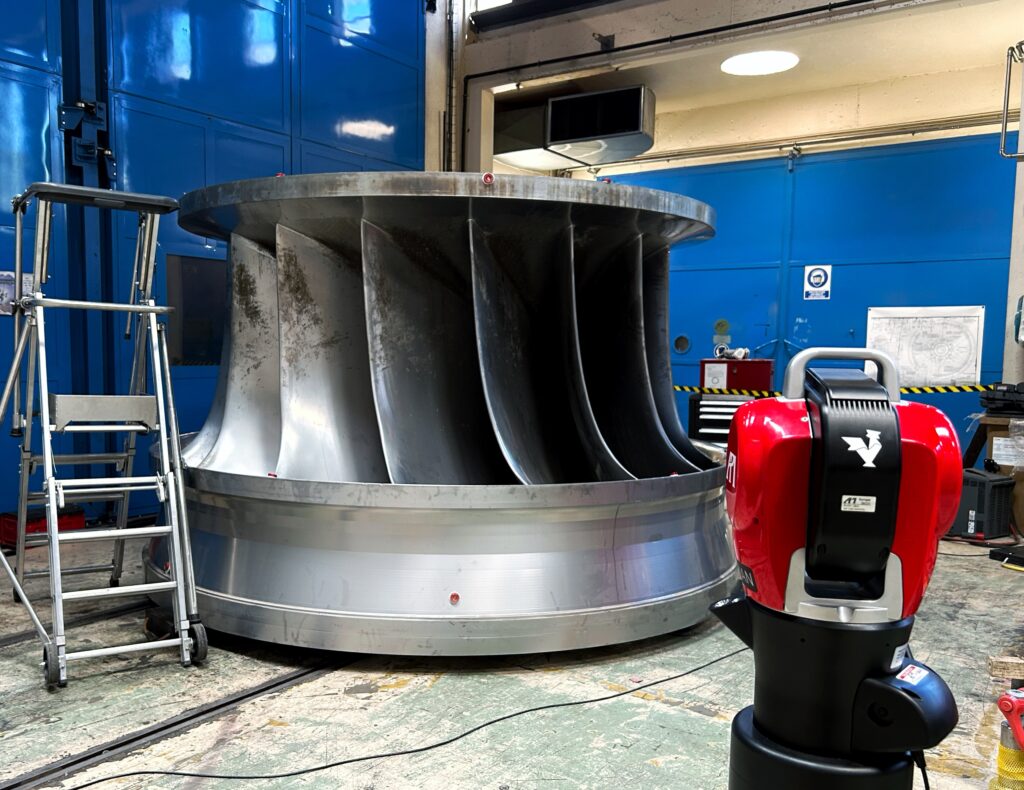

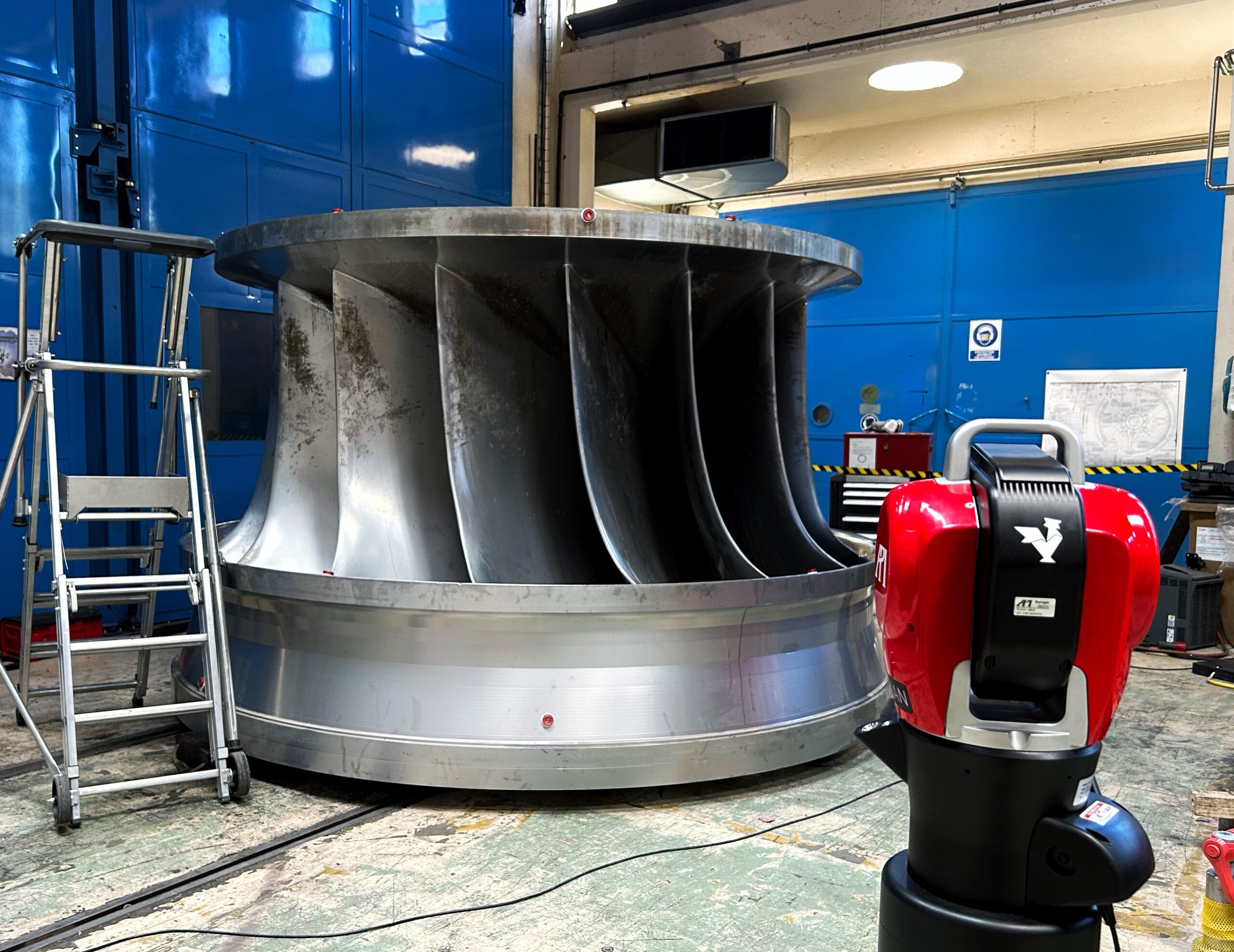

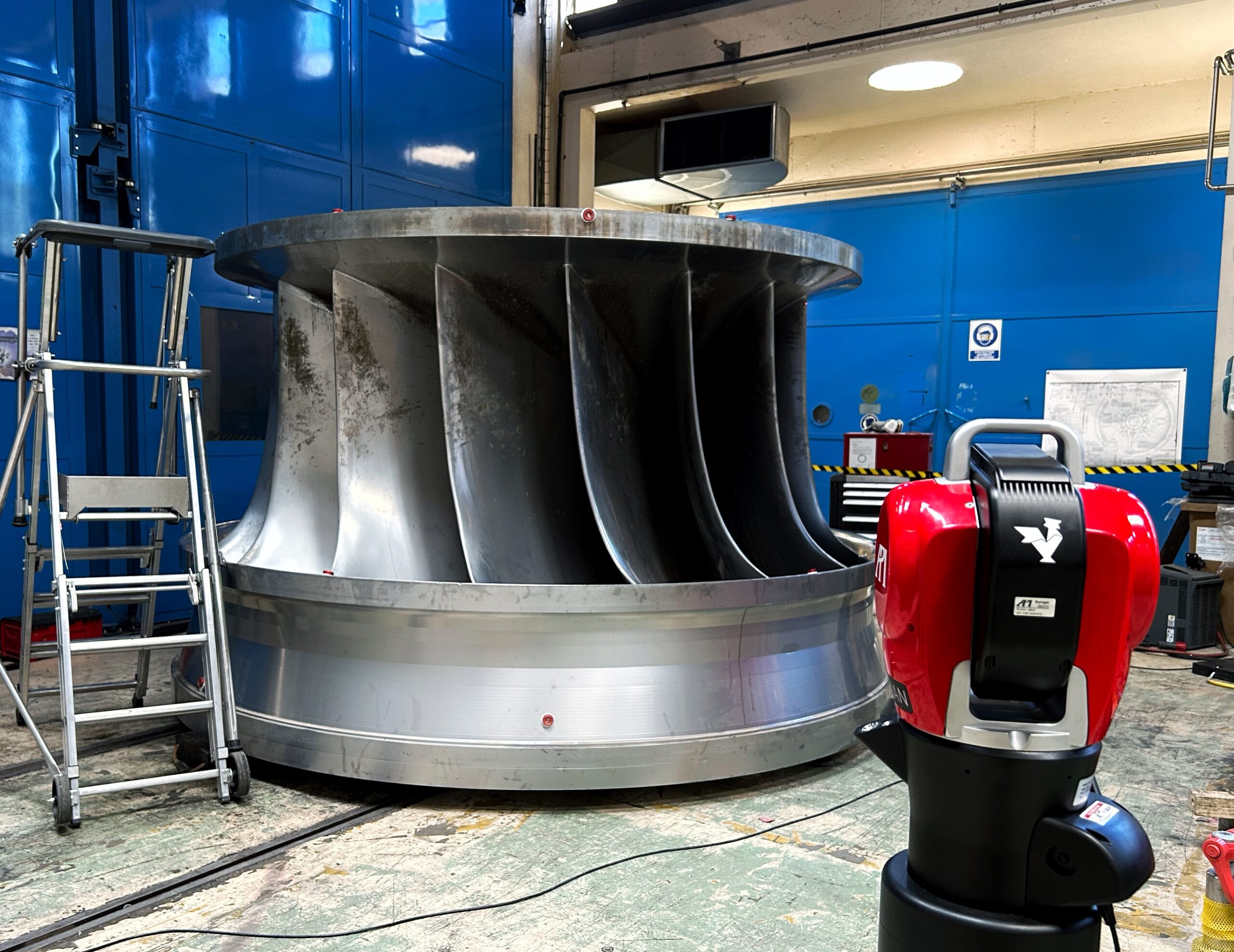

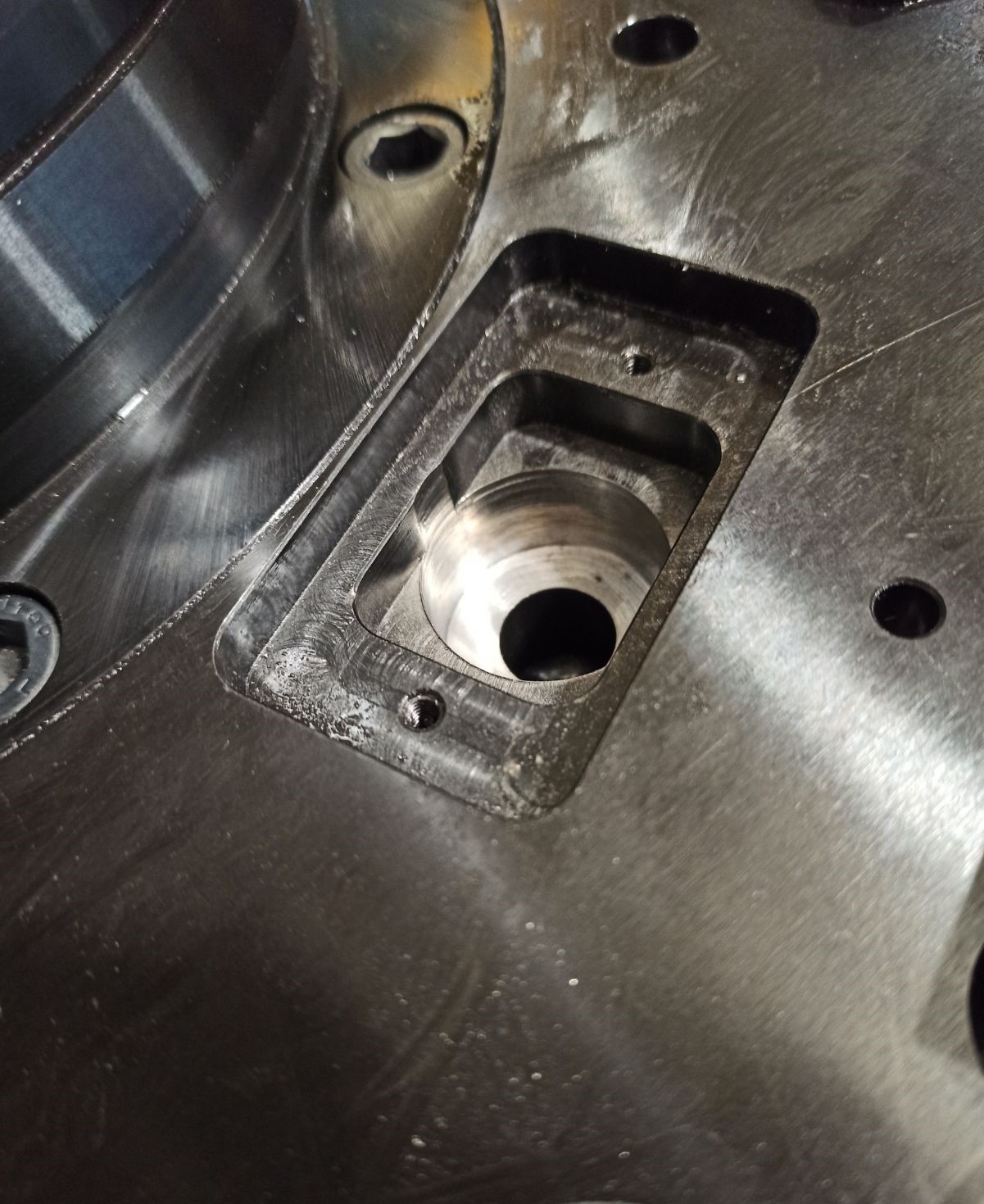

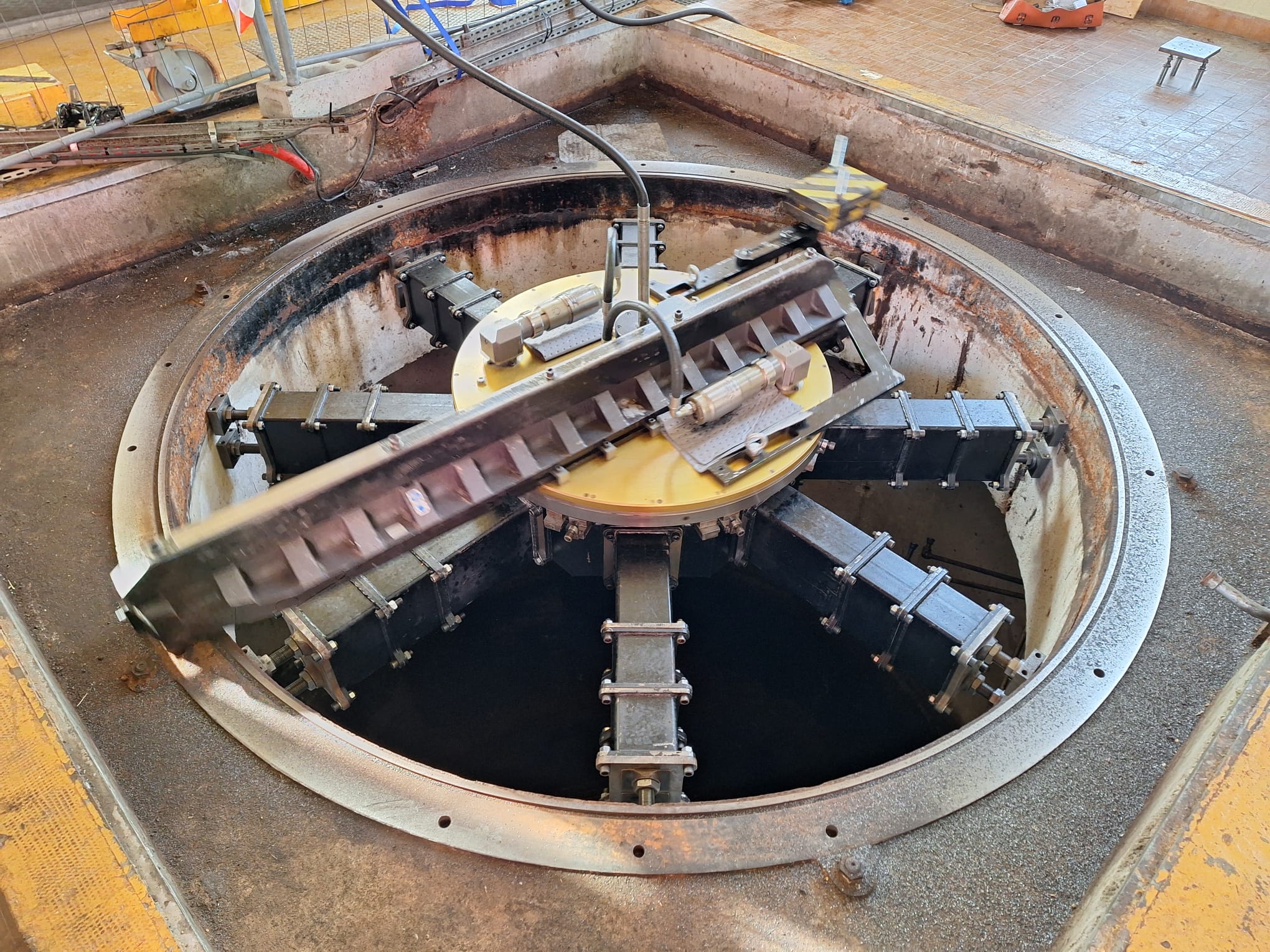

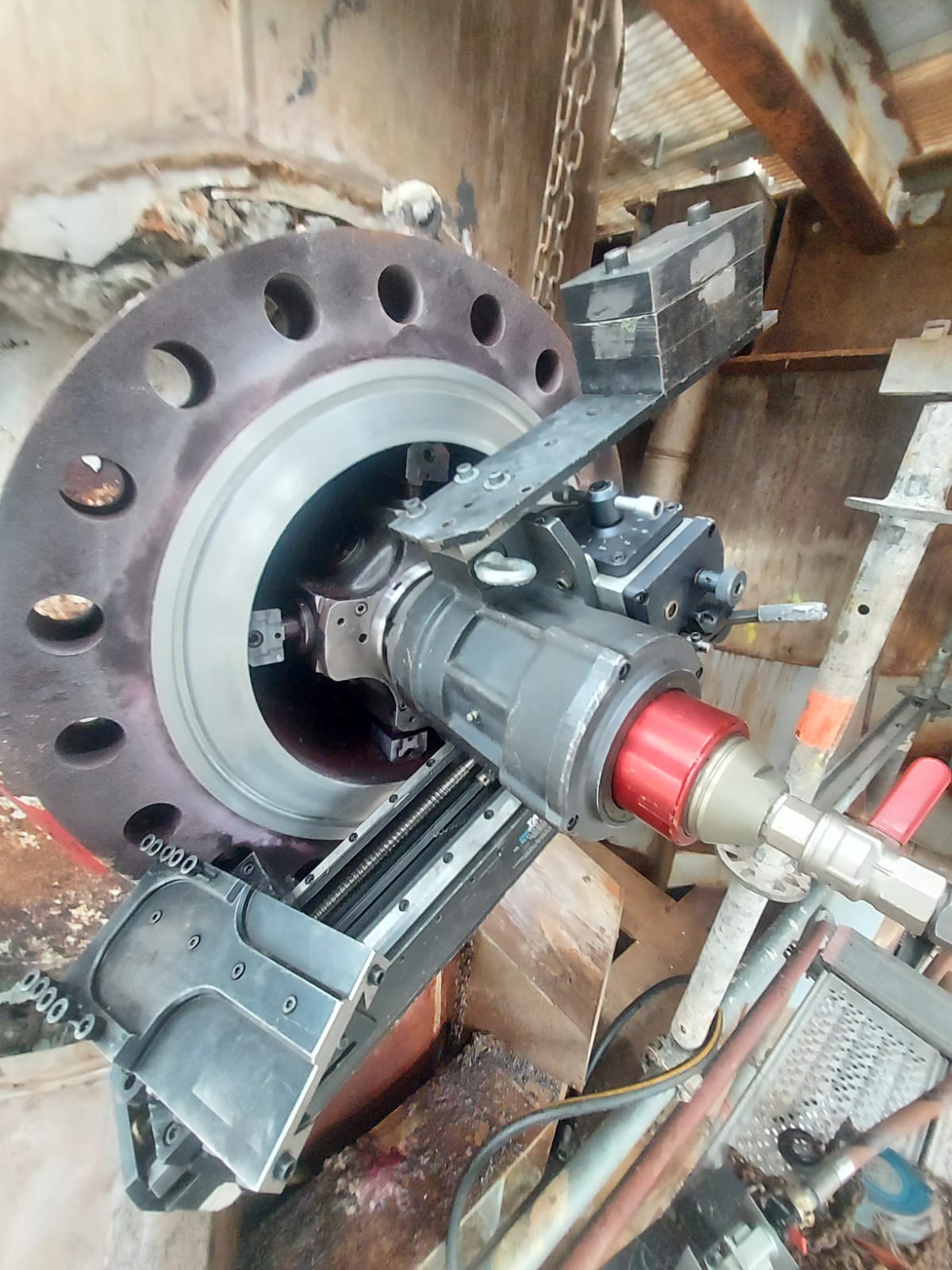

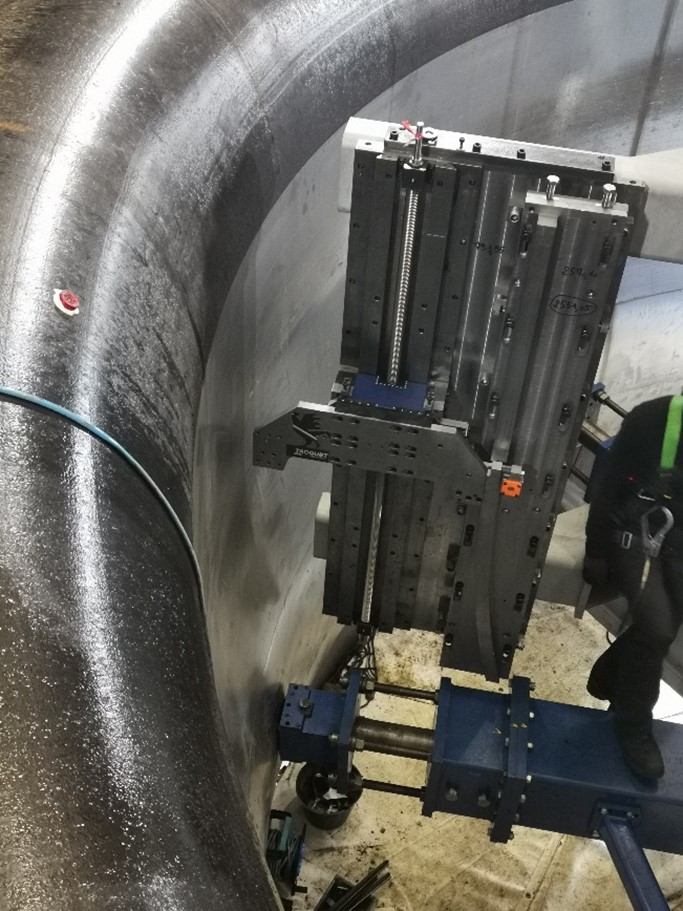

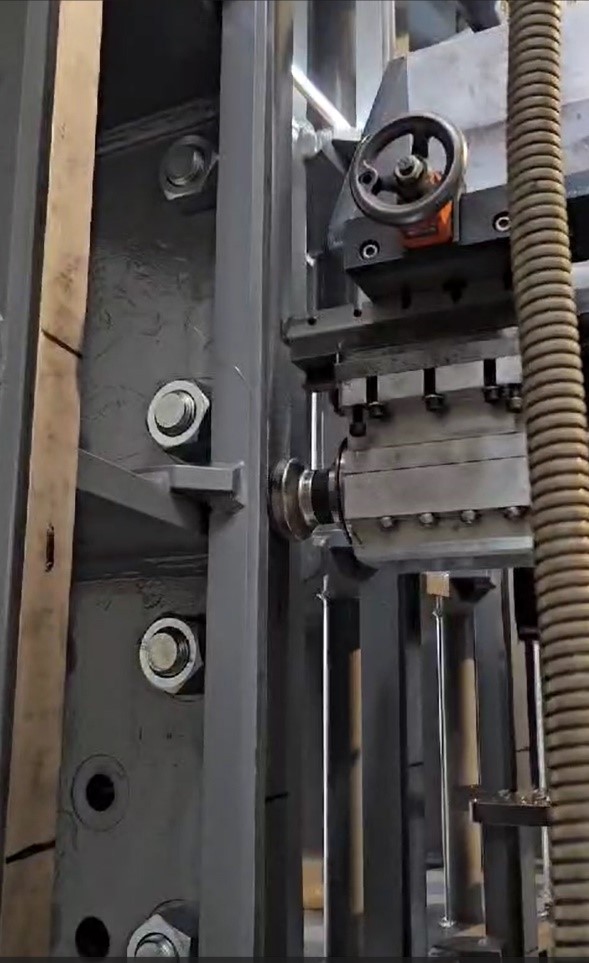

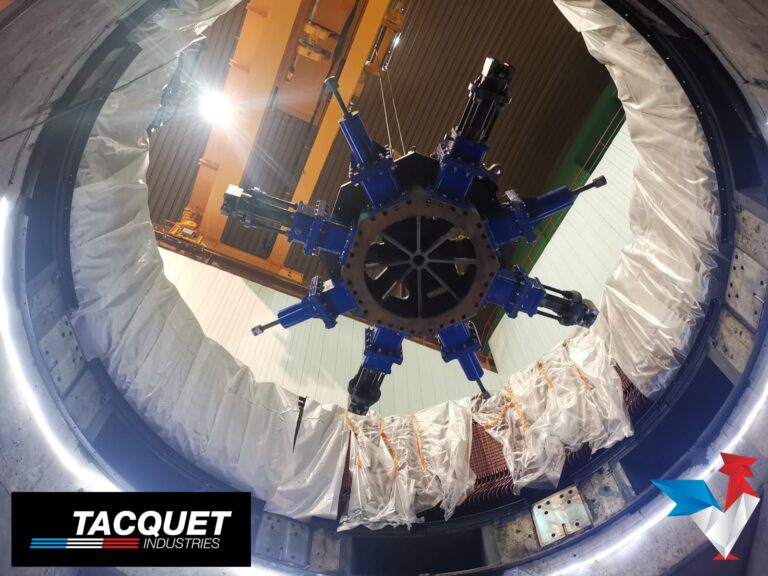

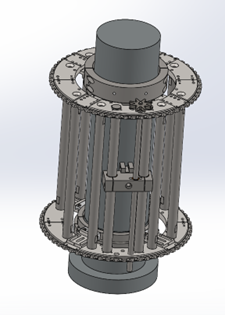

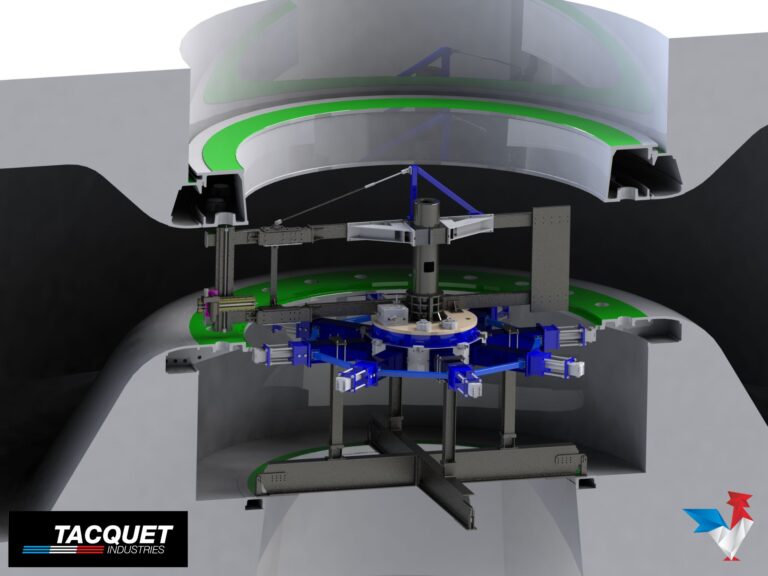

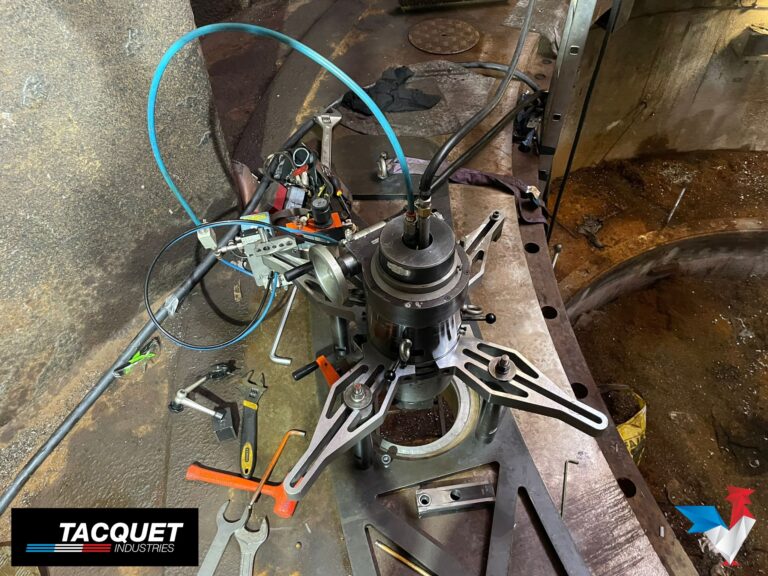

Measurements were taken using a laser tracker, with a reference frame established from the entrance and exit points of the stern tube. The data were then corrected to a standard reference temperature to ensure measurement reliability.

This type of inspection ensures that alignment tolerances remain compatible with the mechanical clearances designed into the system, and that the current configuration is consistent with proper operational performance.

Intervention of 10 June 2024

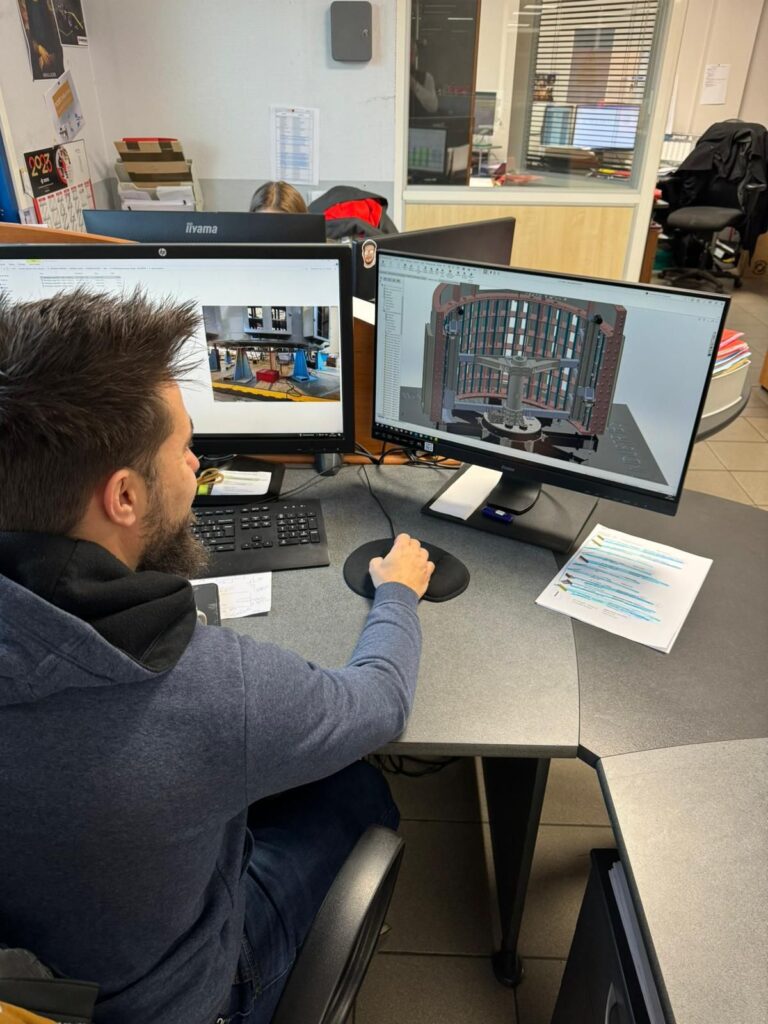

TRACKER LASER