Rehabilitation of a turbine COO

Coo-Trois-Ponts Hydroelectric Power Plant, France

REHABILITATION OF A TURBINE

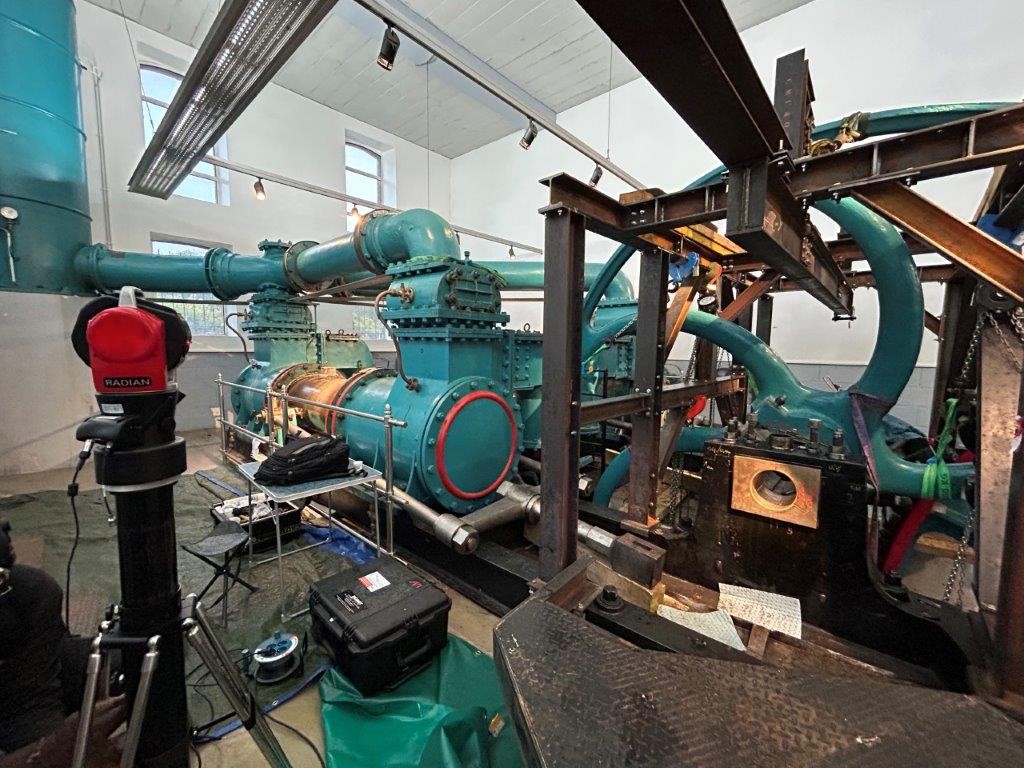

A final intervention to finish the year 2024, machining of group 2 of the magnificent Coo Trois-Ponts power plant.

- ACHIEVEMENT

Rehabilitation for a future overpower:

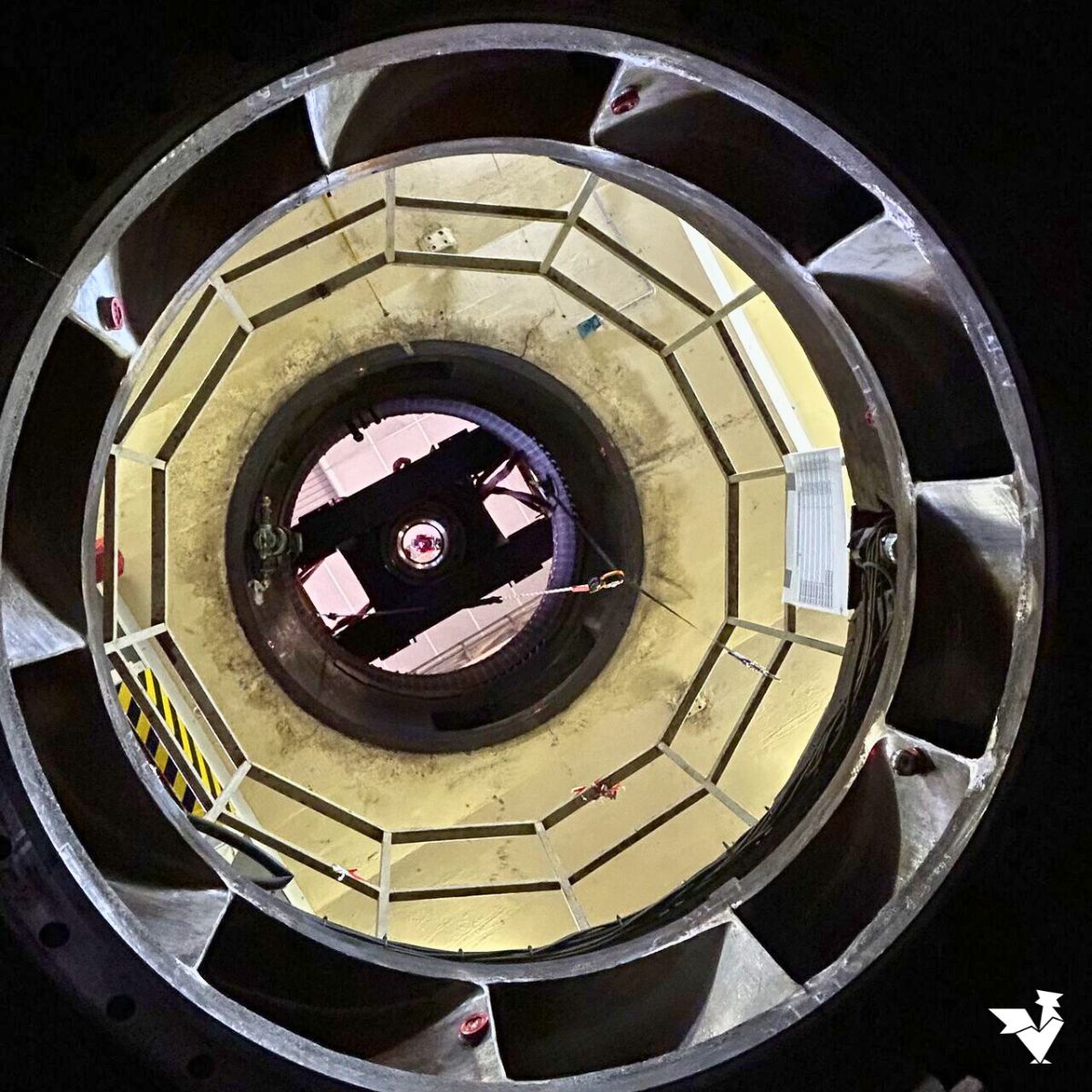

1st step machining of the labyrinth with different bores (about 2500mm diameter) and surface to be realized.

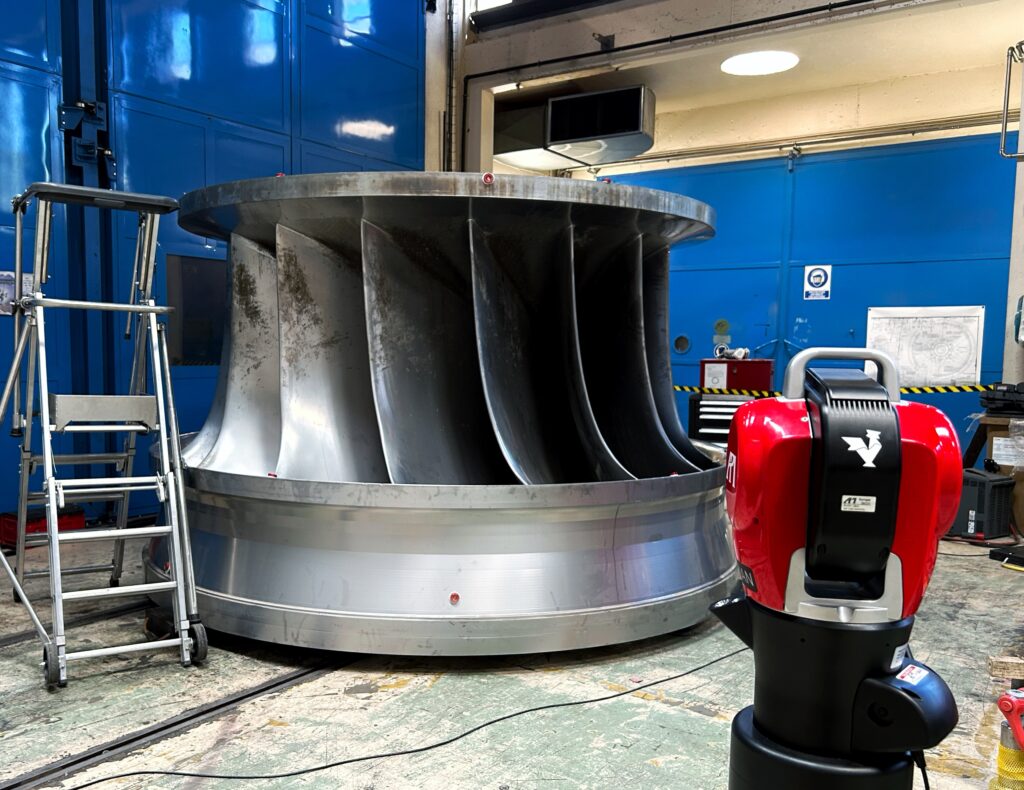

2nd stage machining of the holes at the level of the spiral tarpaulin. (5500mm diameter)