8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

Geometric Inspection and Machining of a Shaft

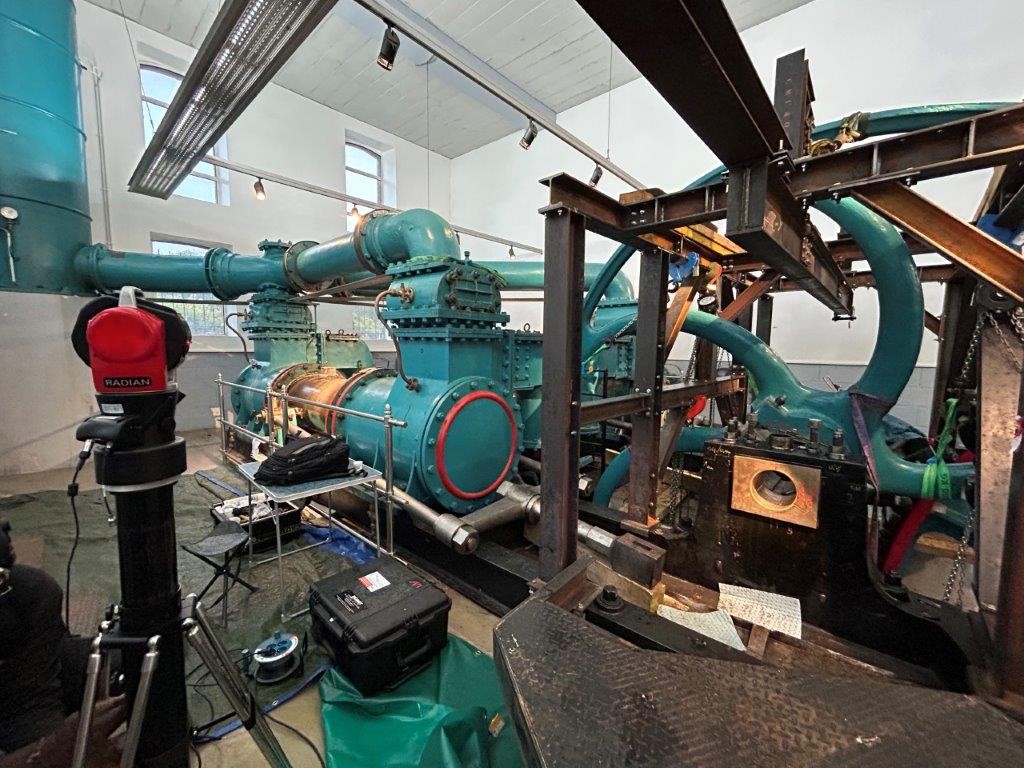

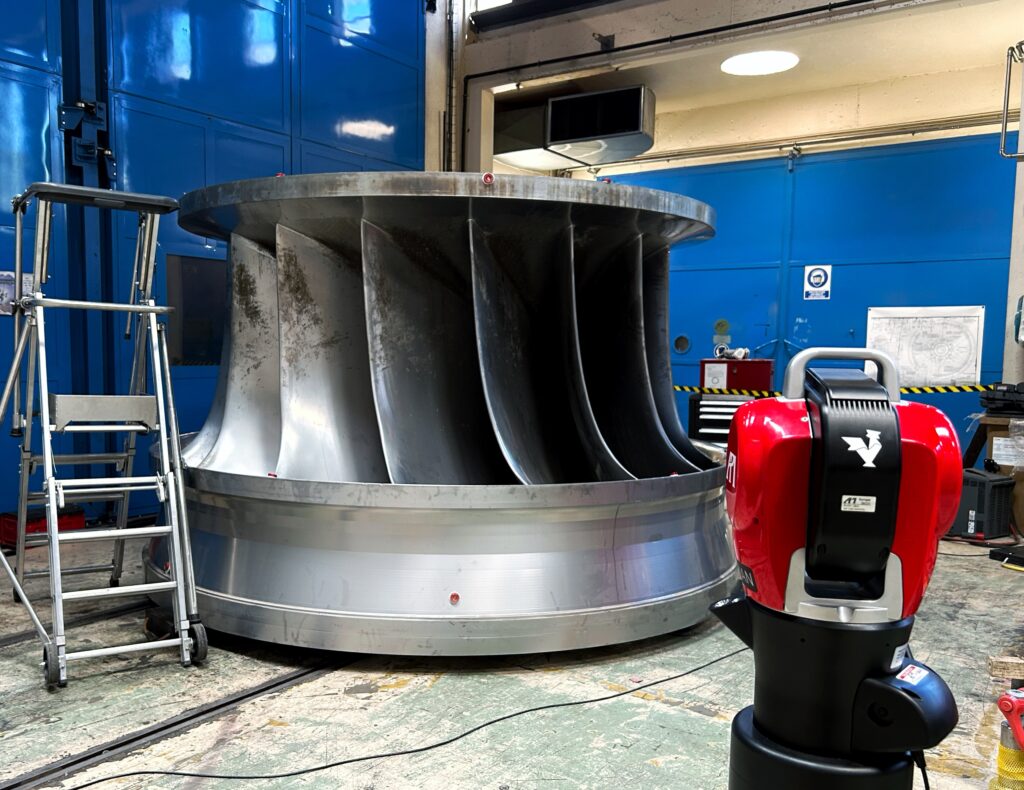

A series of metrology operations was carried out on a crusher shaft, as part of a full inspection and follow-up process before and after corrective machining. These operations were conducted on-site, with the aim of recording the shaft’s initial geometric condition, performing targeted machining, and validating the final dimensions.

Measurements were conducted using a laser tracker, based on a reference system adapted to the shaft’s cylindrical geometry. Thermal conditions were taken into account, with value corrections applied to a standard reference temperature. A specialized metrology software was used to guide the measurement process and optimize data processing.

The intervention included several key stages:

Initial inspection of the shaft cylinders, distinguishing between previously machined and raw areas,

Machining setup, including the installation of a support ring for machine guides,

Orbital machining of the targeted surface,

And finally, a geometric validation check post-machining.

This comprehensive approach ensured restoration in compliance with specifications, providing rigorous dimensional traceability throughout all stages of the process—before, during, and after the intervention.

Intervention of 31 August 2024

TRACKER LASER