8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

BORING

On-site Boring

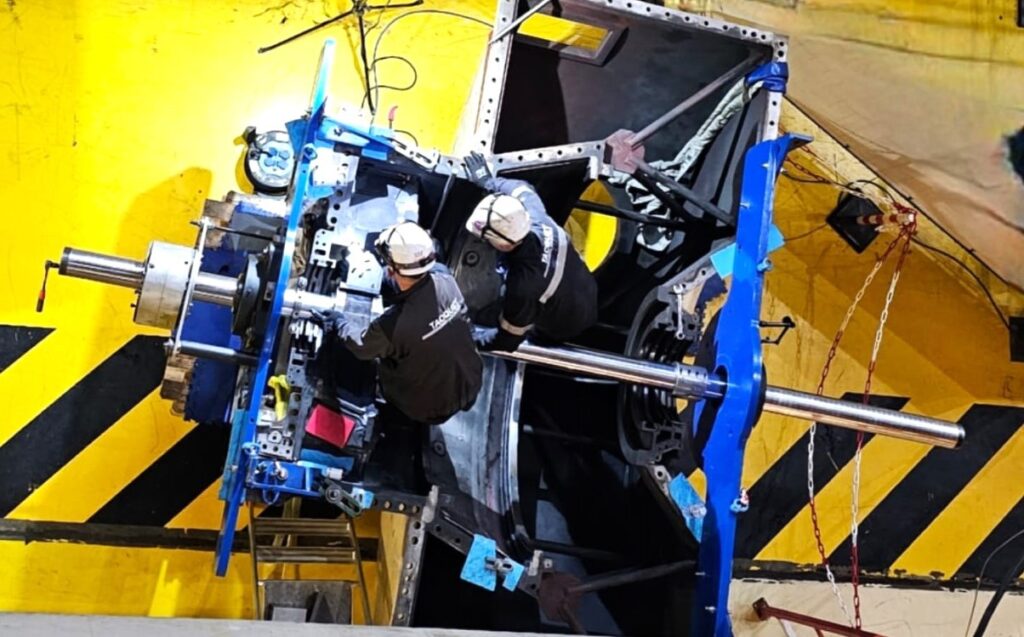

Precision and Continuity Without Dismantling

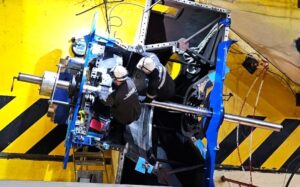

At TACQUET INDUSTRIES, we perform on-site boring operations with a high level of precision, directly on your fixed or mobile equipment. This technique allows us to correct, realign or restore worn, ovalized or deformed cylindrical bores — without having to dismantle your machinery.

When Is On-site Boring Recommended?

On-site boring is especially suited for situations where access is limited, tolerances are tight, or disassembly would lead to costly production downtime.

We operate on a wide range of mechanical configurations, including:

Line boring (multi-bearing alignment)

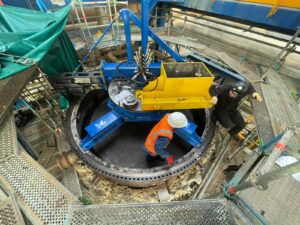

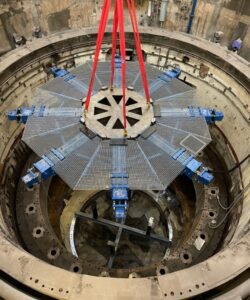

Turbine wells (hydropower plants)

Clevises or articulated mechanical assemblies

Piston sleeves

Thanks to our fleet of portable boring machines, we can handle diameters ranging from a few millimeters up to 7 meters, in France and worldwide.

Technical Resources Adapted to Every Project

Our teams operate with over 200 portable boring machines, adaptable to even the most complex configurations. Using modular, motorized tools with automatic or manual feed, we guarantee surface finishes and tolerances that meet your most demanding specifications.

Each operation is preceded by rigorous dimensional inspection and can be supplemented with welding, re-alignment, facing, or complementary machining, depending on requirements.

Your Benefits

- No major dismantling: on-site intervention only

- Time savings: reduced production downtime

- Guaranteed quality: compliance with strict tolerances

- Flexibility: 24/7 emergency response

Boring in Sensitive Environments

Our know-how allows us to operate in highly regulated sectors: nuclear, hydraulic, naval, energy, petrochemical, steel industry, and more. Our teams are trained and certified to work in high-risk zones (ATEX zones, radiation-controlled areas, etc.).

A Rigorous QHSE Commitment

ACHIEVEMENTS

For any request for quotation or to discuss your project of machining on site, do not hesitate to contact us. Our team is at your disposal to advise you and offer the most appropriate services to your expectations. We will be happy to support you in the success of your machining projects.