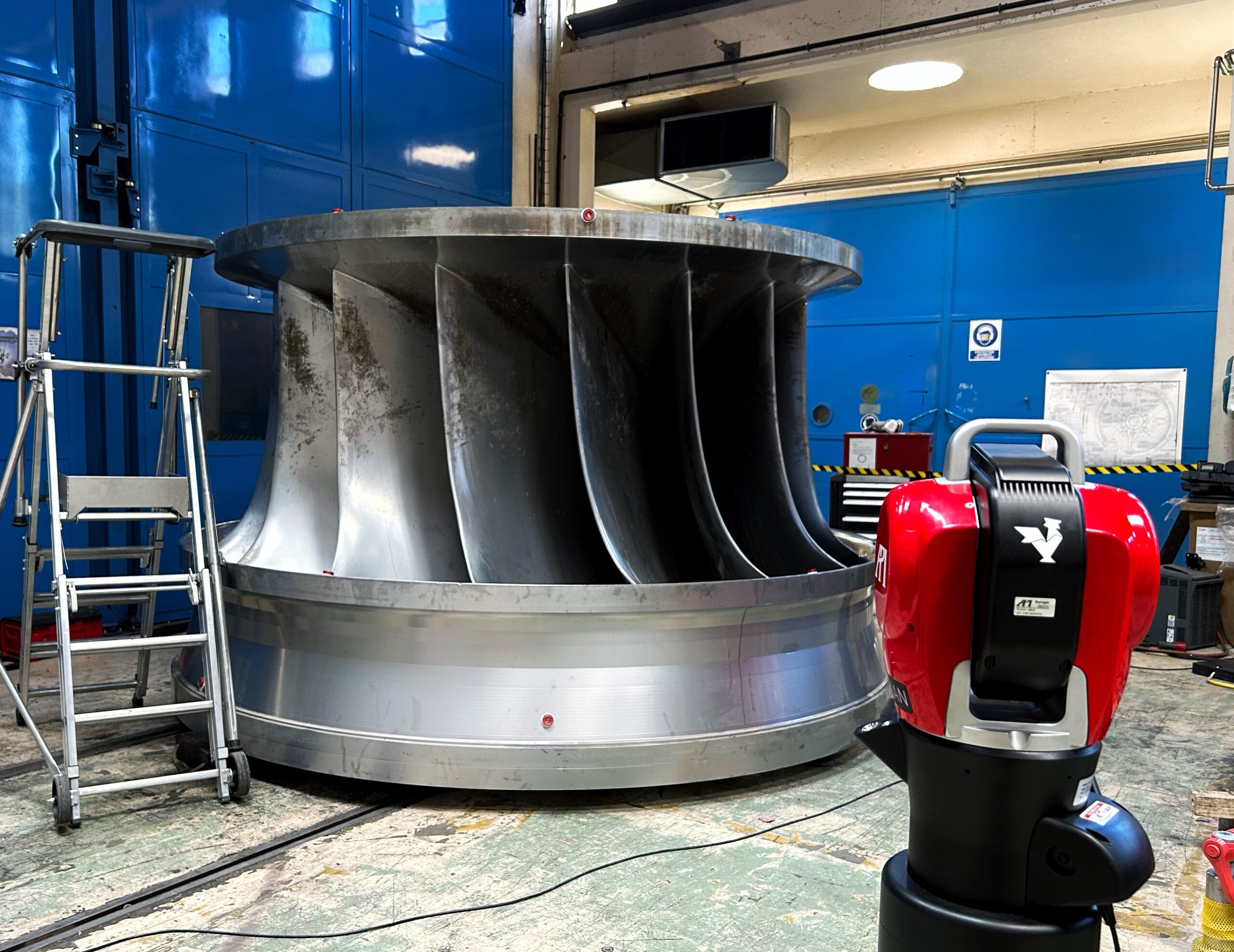

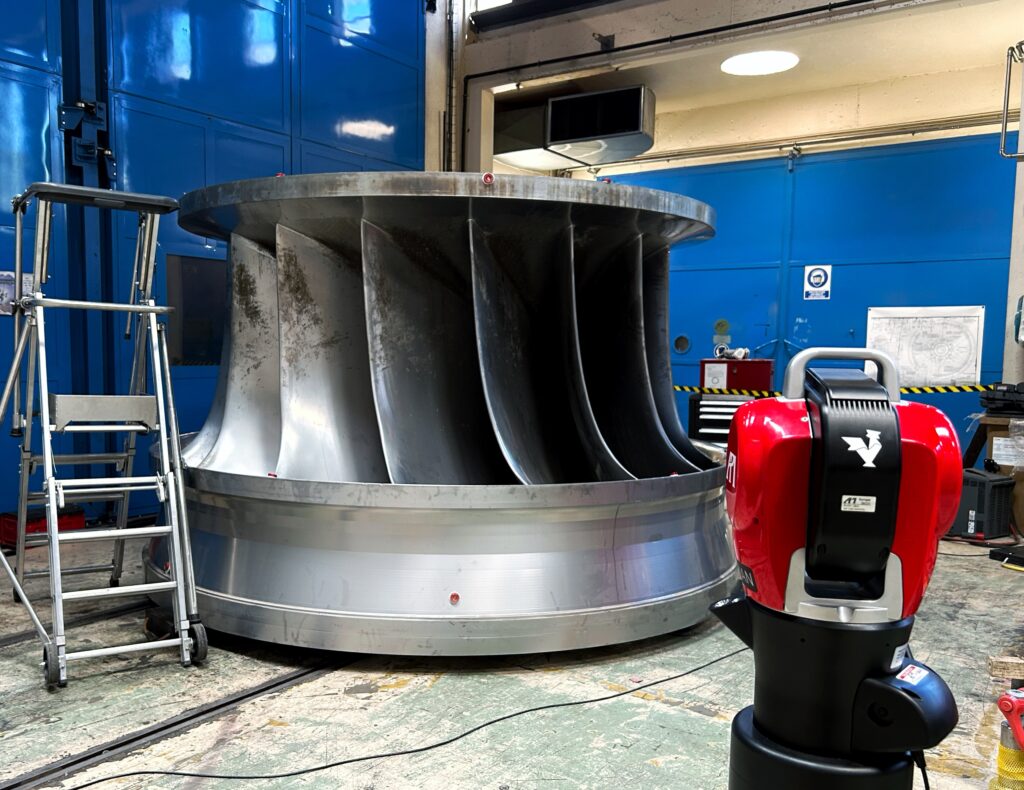

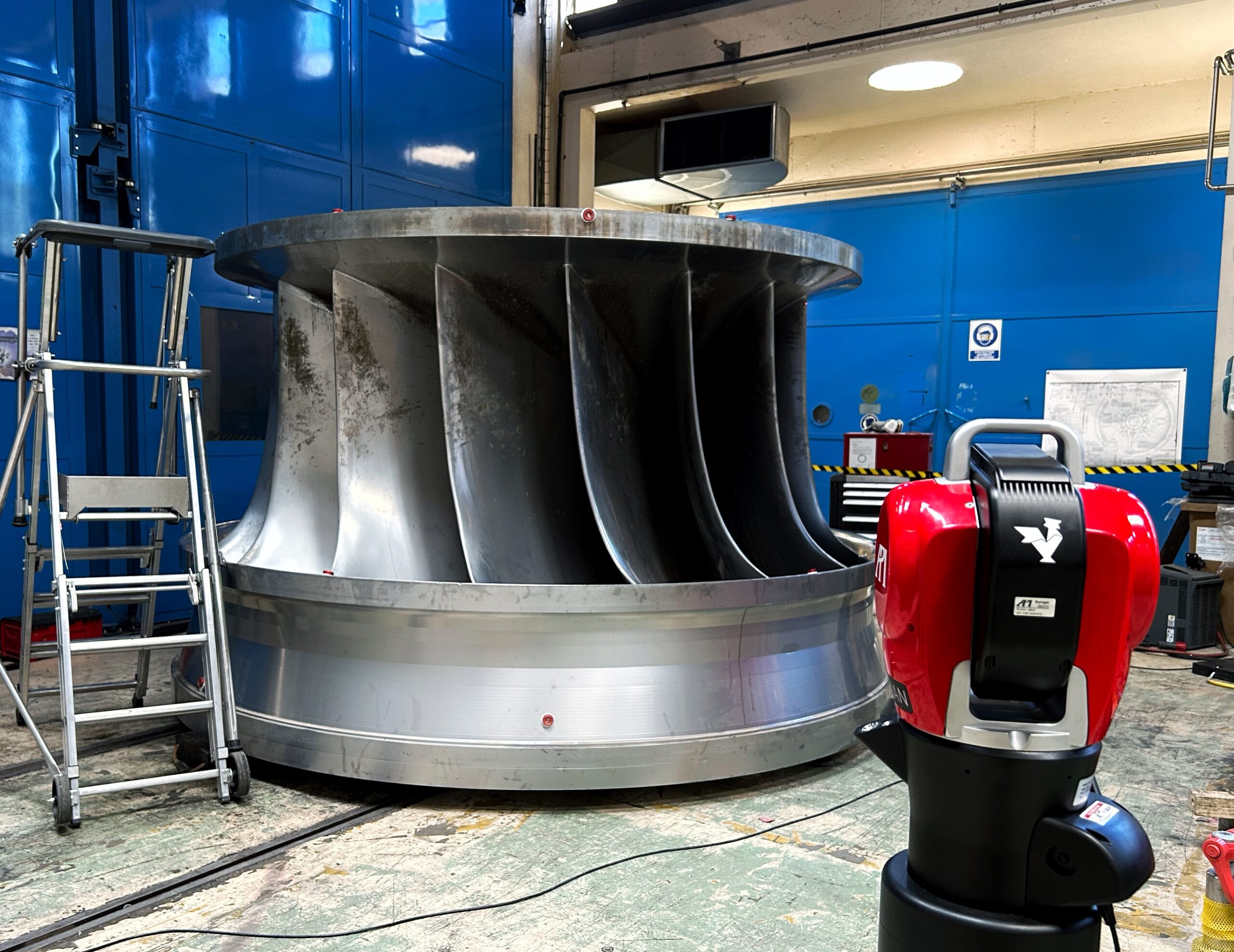

Tracker laser

Initial Metrological Inspection of a Runner Francis

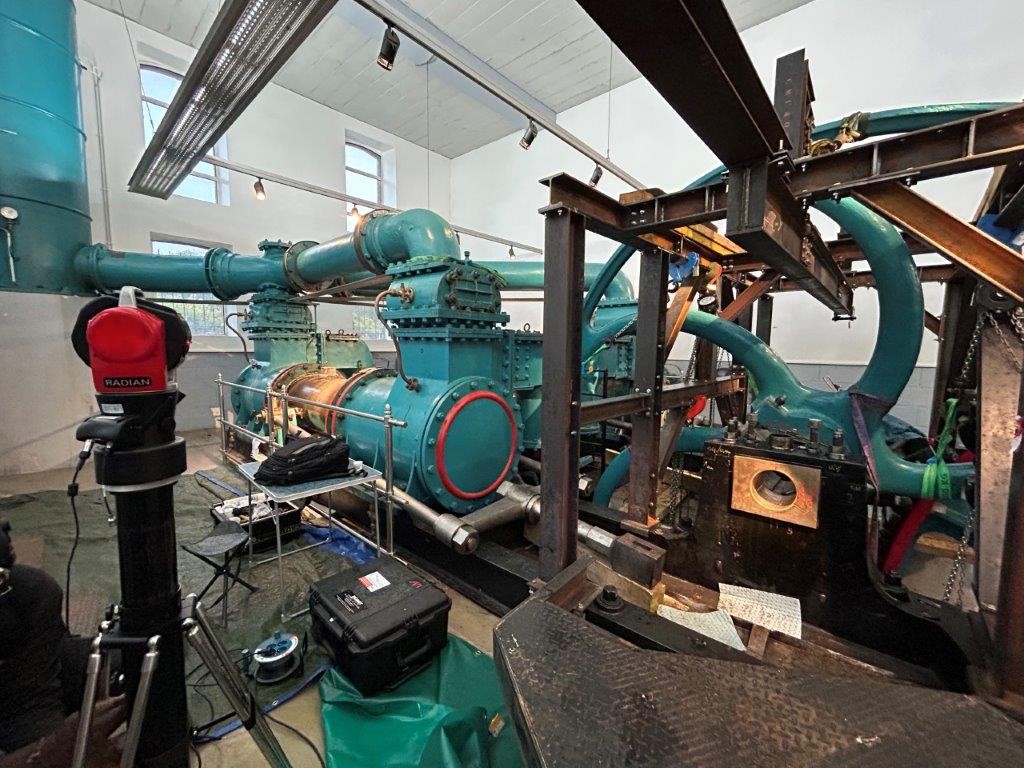

A geometric inspection was carried out on the runner of Group G2 at the Mallemort hydroelectric plant, as part of an initial dimensional survey prior to any mechanical intervention.

The aim of this mission was to verify the compliance of the runner’s shapes, dimensions, and functional geometries, based on a set of control points defined in the inspection plan provided by the client. All measurements were conducted on-site using a laser tracker, in a controlled environment and with consideration for local thermal conditions.

A custom reference frame was established around the part’s mounting axes, allowing for consistent analysis of flatness, concentricity, perpendicularity, and cylindricity deviations. Special attention was given to the coupling face, key diameters, and the angular distribution of machined reference marks.

All data required within the inspection scope were collected in line with client expectations. The final report includes a compliance table and a complete set of documentation to support future monitoring or rework operations.

This type of intervention reflects a rigorous quality control approach, essential for the performance and durability of critical hydromechanical components.

Intervention of 21 May 2024

TRACKER LASER