8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

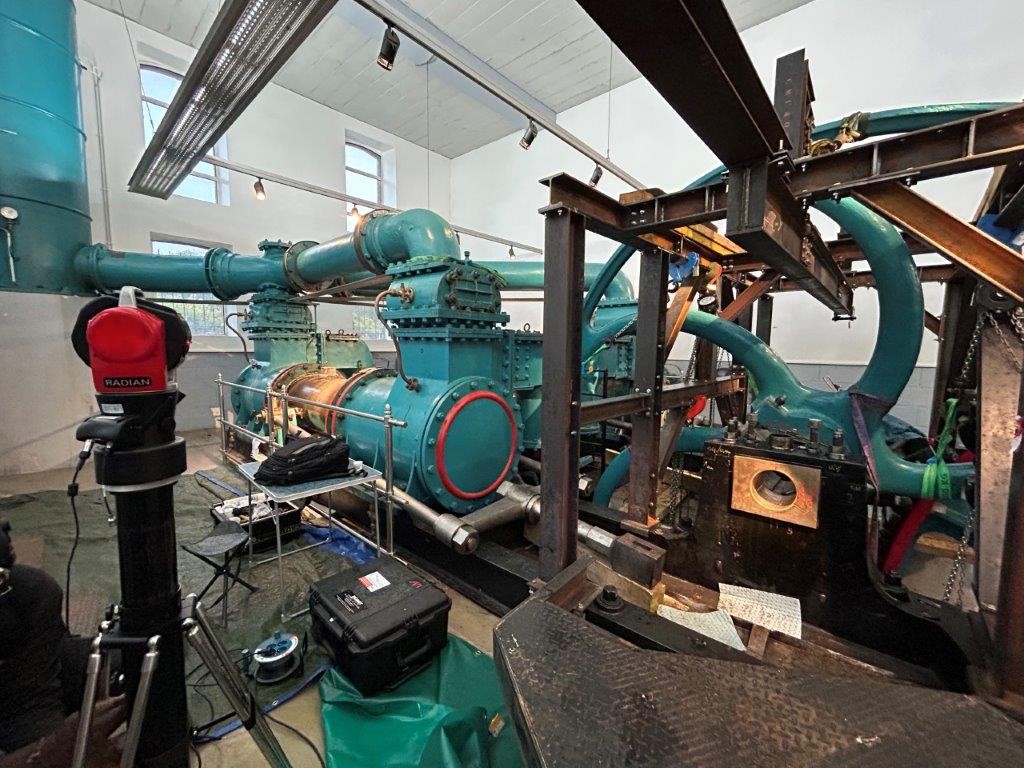

Metrology Inspection by Laser Tracker on a Pelton Unit

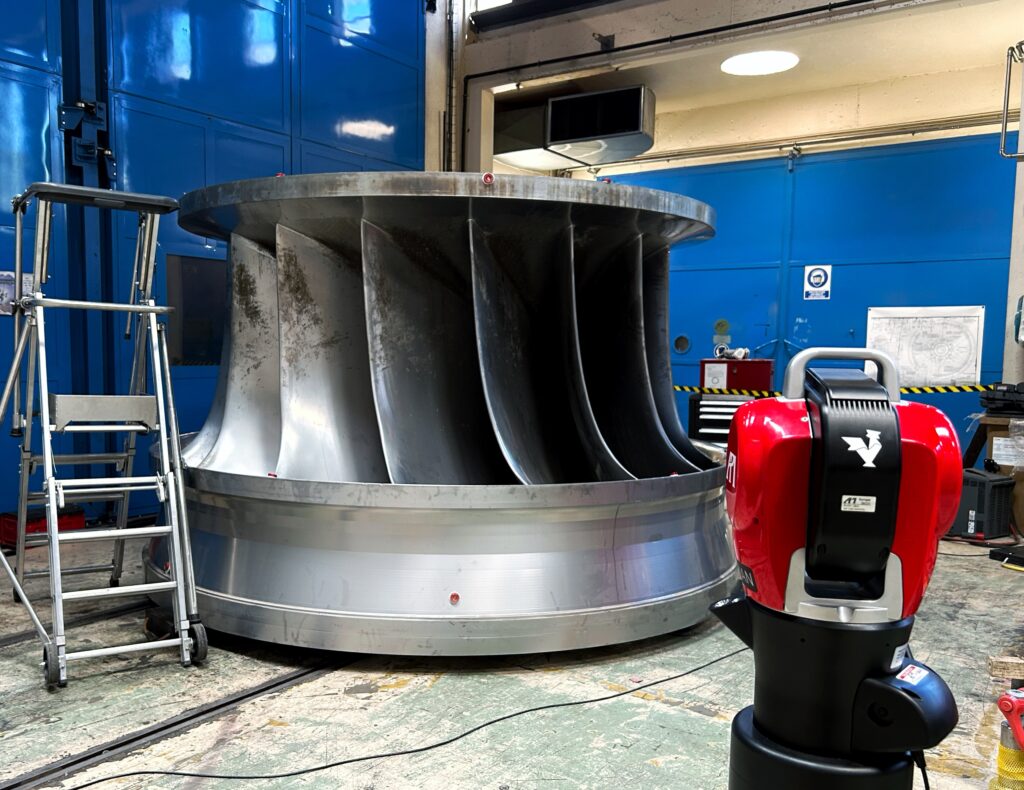

As part of an on-site industrial metrology intervention, a dimensional inspection was performed on a Pelton unit, focusing on both the fixed and movable covers, assessed directly in their functional configuration.

The objective of this operation was to verify the geometric conformity of the assembly, ensuring optimal fit between the movable and fixed components, as well as maintaining the stability and precision of the installation.

A high-precision laser tracker was used to carry out the measurements, providing fast and reliable acquisition of geometries, even in constrained environments. The inspection was conducted with the covers held in their actual operational positions, ensuring the relevance of the measurements, and then removed afterward.

The analysis enabled evaluation of clearances, alignments, and geometric consistency between the different components. At the end of the inspection, a detailed report was issued, including measurement data and recommendations for potential adjustments or long-term monitoring.

This type of intervention highlights the value of laser tracker inspections for large structures or complex assemblies and supports dimensional control as a key factor in equipment reliability.

Intervention of 17 January 2025

TRACKER LASER