8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

Geometric Measurement of a Hydraulic Elbow and Kaplan Runner

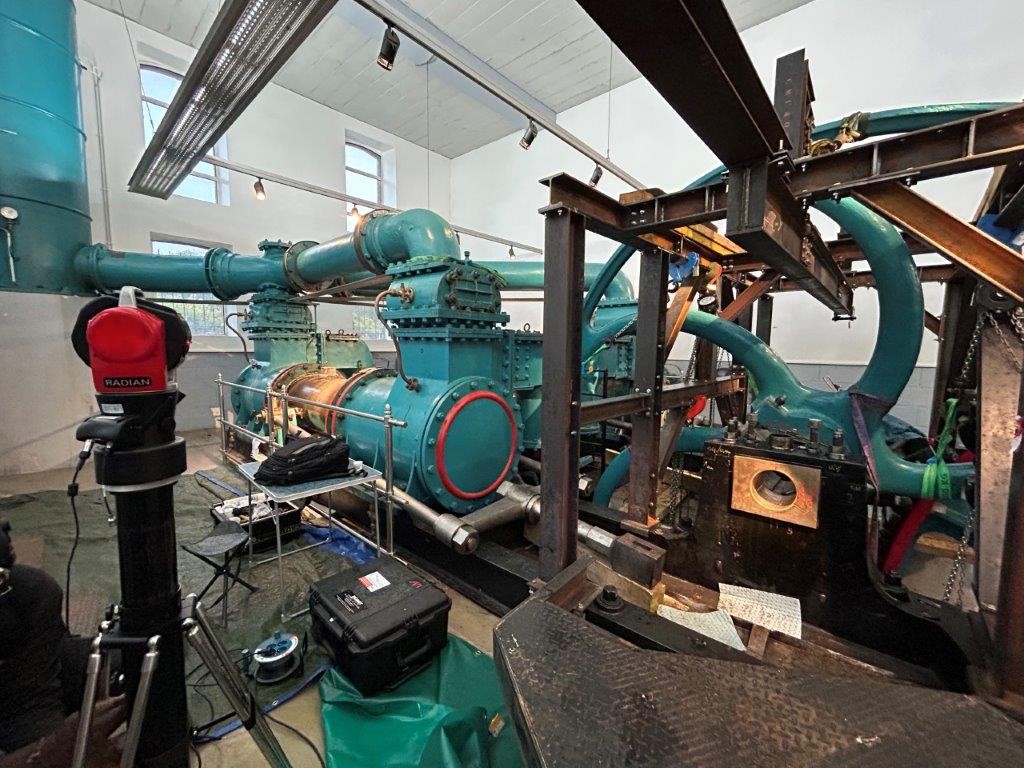

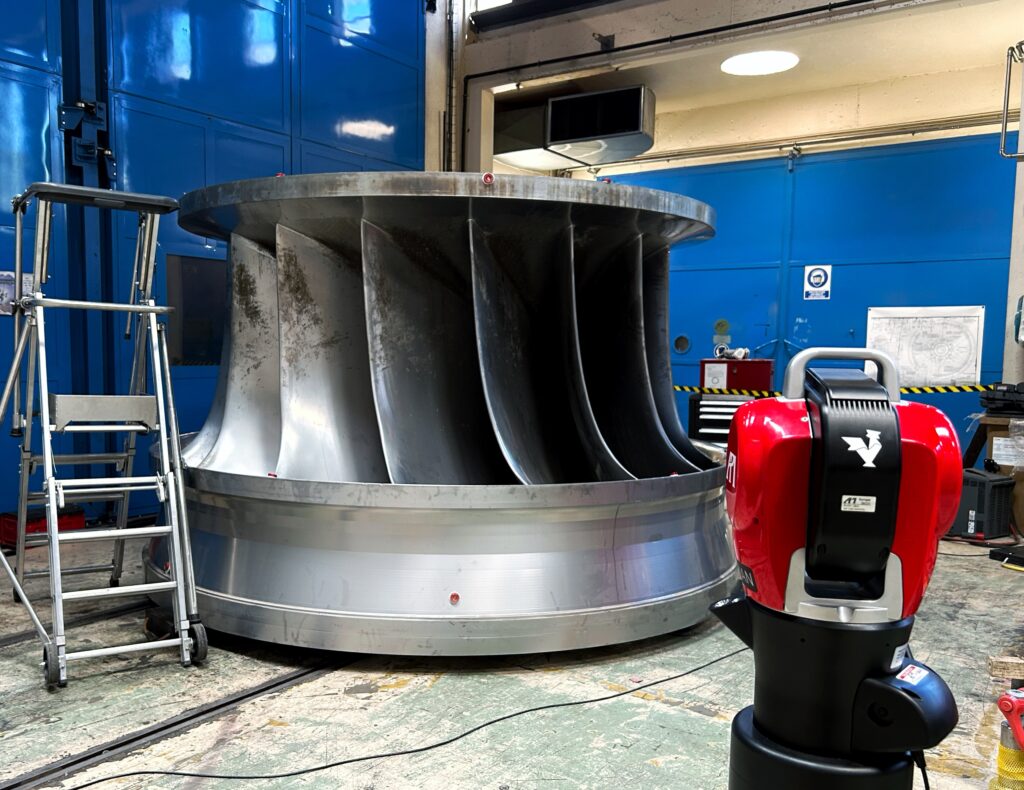

A metrology inspection was carried out on an assembly consisting of a hydraulic elbow and a Kaplan runner, in accordance with the specifications of an established inspection procedure. The operation was conducted both on-site and in the workshop, with measurements taken at various stages of the process, including phases before and after the removal of certain components.

The inspections focused on several key elements: runner diameter, axial position of the blades, perpendicularity of the elbow, and various internal dimensions. A complete survey of the bearing was also performed, with particular attention paid to its centering and perpendicularity.

Additional measurements were taken on an old runner shroud, whose surface condition imposed certain limitations on the analysis. A comparison with the 3D model made it possible to visually identify deviations from the theoretical geometry, particularly in areas with excess material or recesses.

All points outlined in the inspection plan were covered, enabling the establishment of a comprehensive dimensional assessment of the equipment for operational use or future technical interventions.

Intervention of 16 October 2024

TRACKER LASER