8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

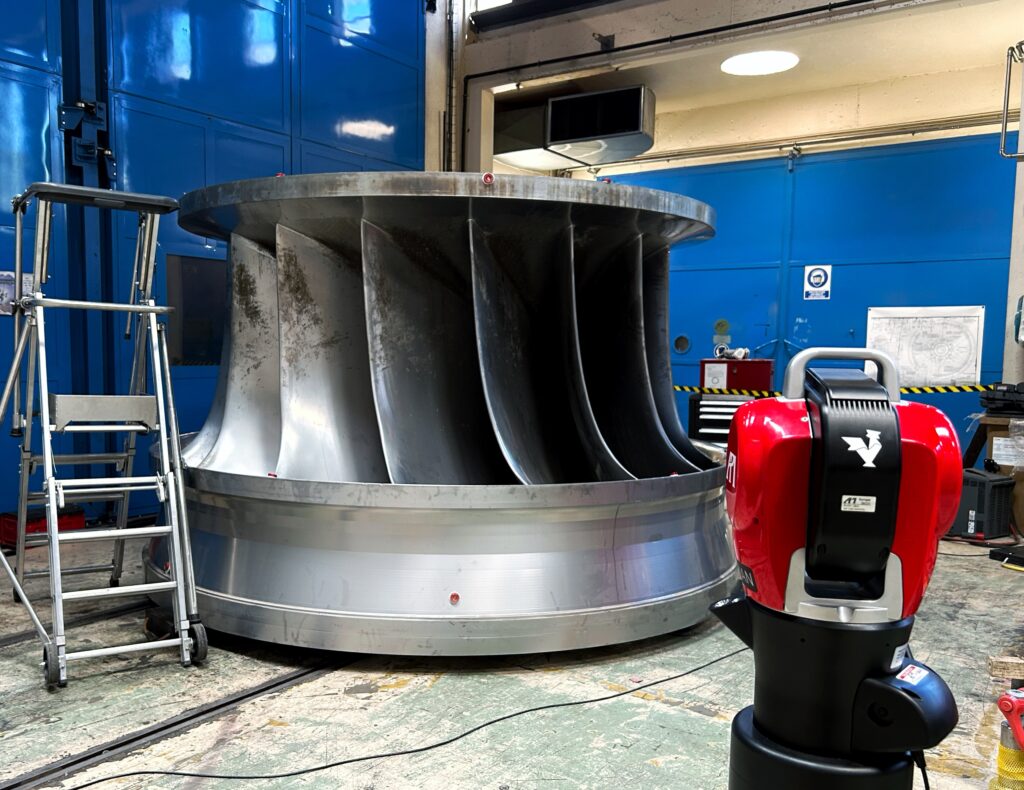

Geometric and Dimensional Inspection of a Francis Runner

As part of a specialized metrology operation, a comprehensive geometric and dimensional inspection was carried out on a Francis runner, a key component of a hydraulic turbine.

The purpose of this intervention was to verify the conformity of the runner’s surfaces and blades, ensuring adherence to manufacturing tolerances and overall uniformity. These criteria are critical to guarantee hydraulic performance, durability, and optimal balancing during operation.

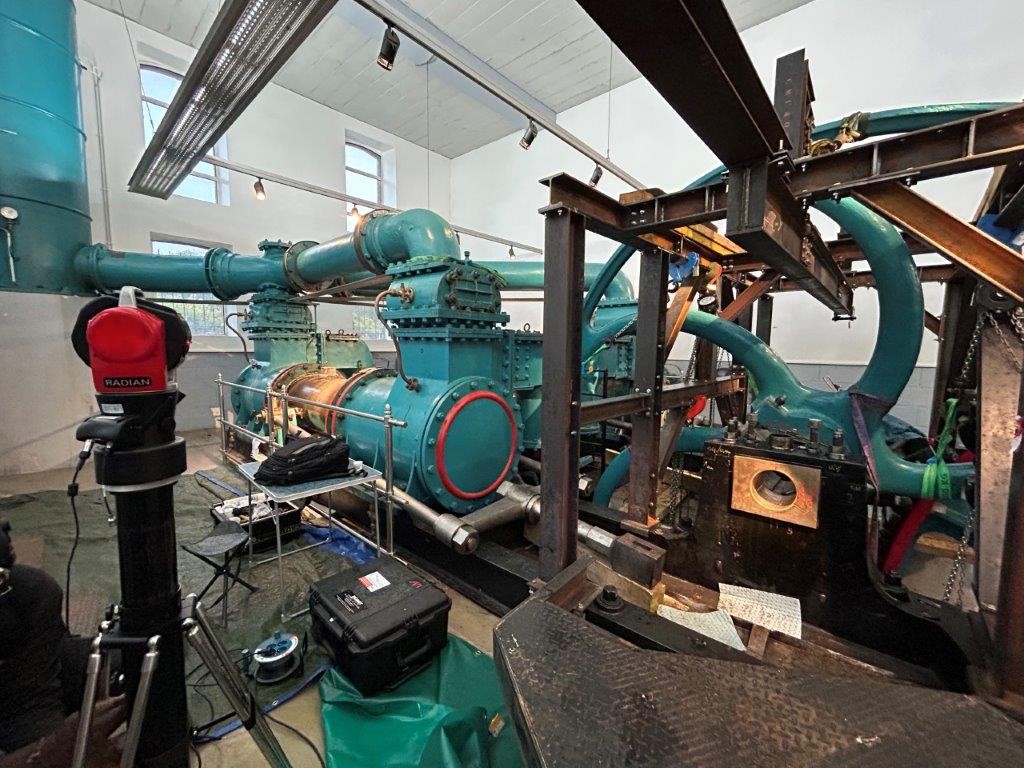

To meet these requirements, high-precision measuring tools were deployed on-site, including a laser tracker, enabling full coverage of the component’s complex geometry.

Measurements focused on several aspects: blade profile and thickness, geometry of the support surfaces, angular distribution, and analysis of overall shape deviations. All data was compiled into a dedicated report designed to assist technical teams in validating, monitoring, or adjusting the component as needed.

This type of inspection helps secure the assembly or recommissioning phases by providing a reliable and documented database of the runner’s actual condition.

Intervention of 18 December 2024

TRACKER LASER