Hot tap DN350 on DN500 header

DN350 Hot Tap on DN500 Potable Water Header

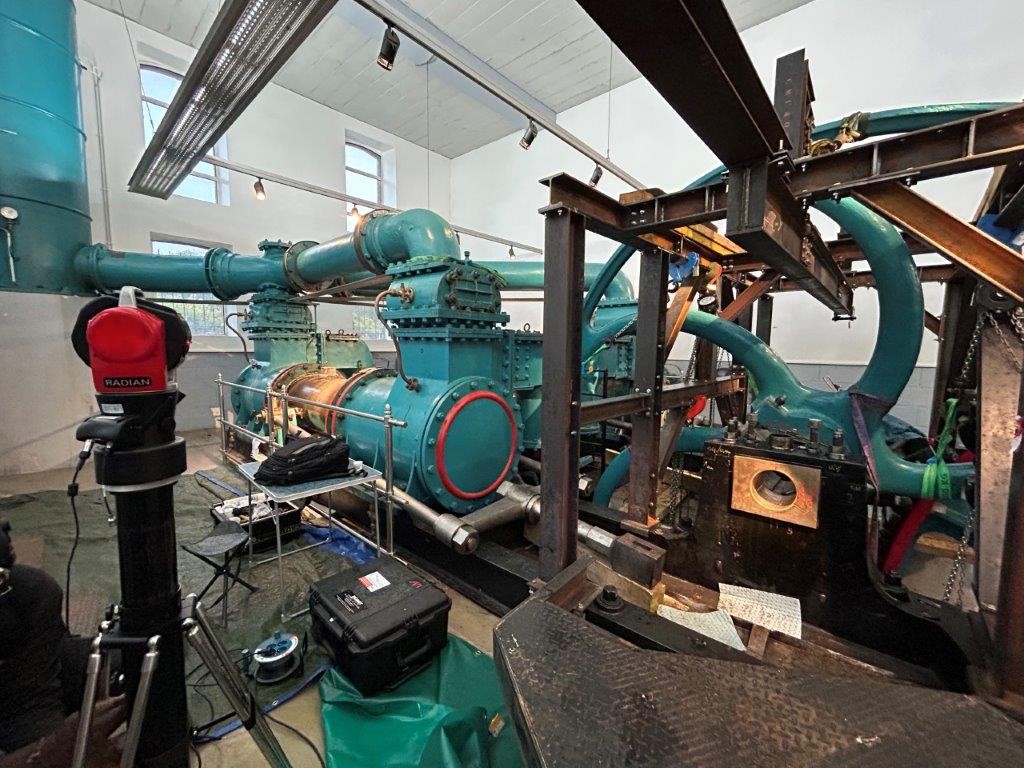

Our teams carried out a DN350 PN10 hot tap on a DN500 potable water header, with no service interruption.

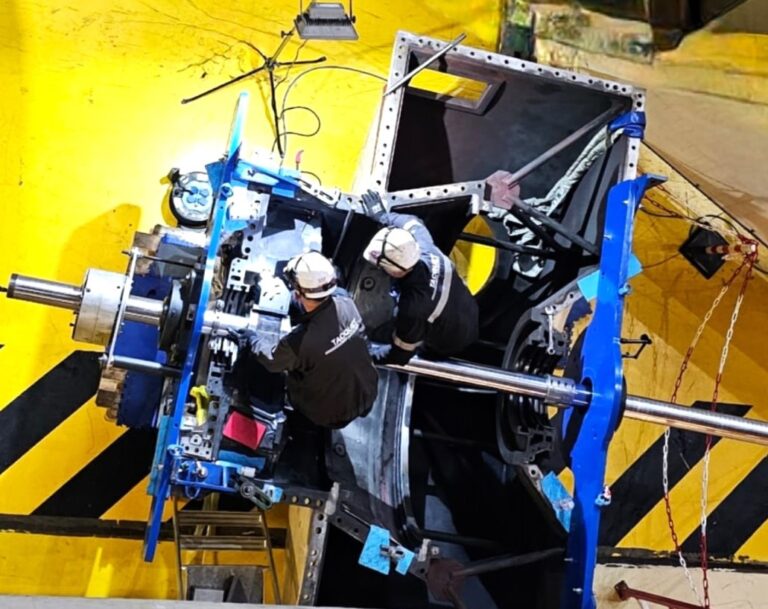

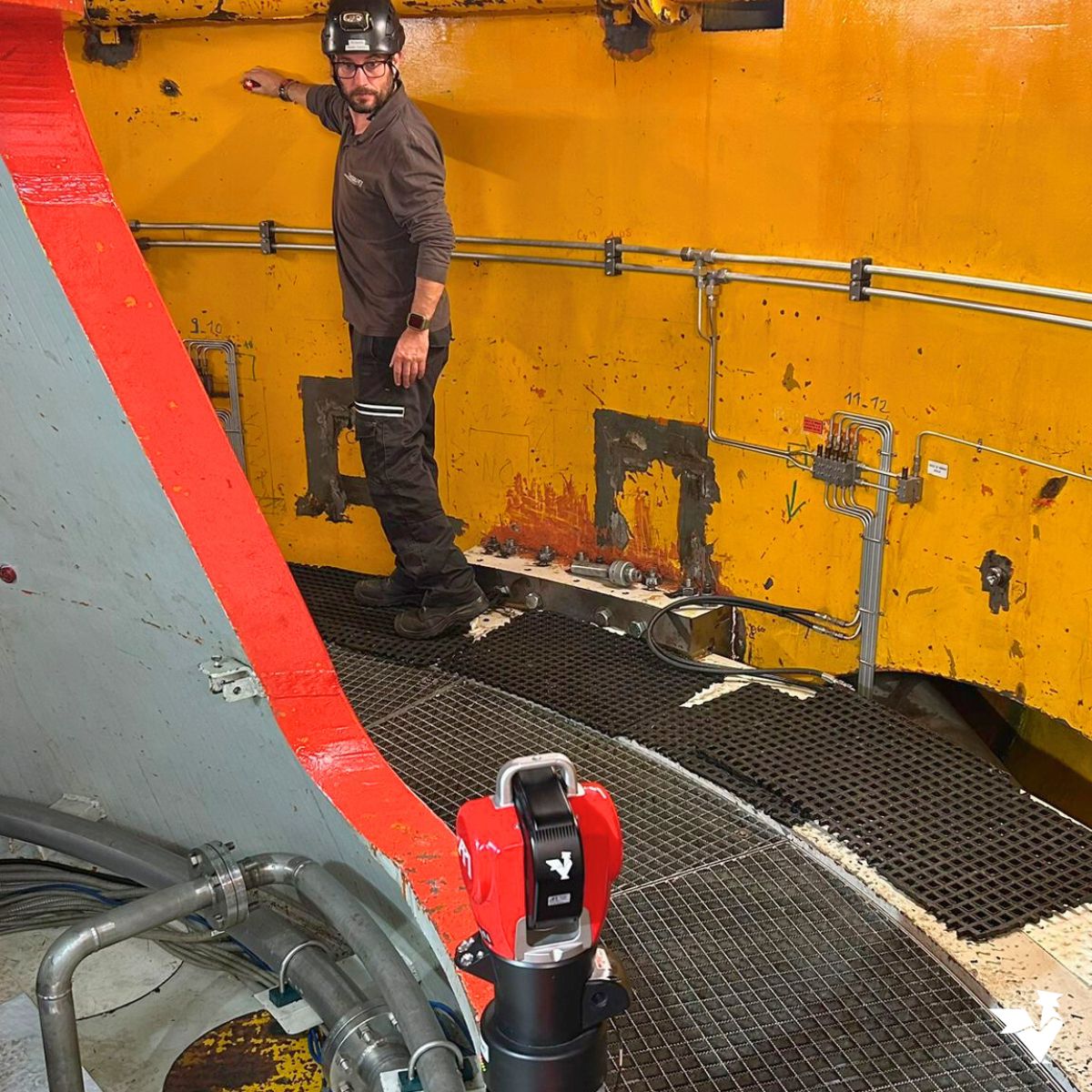

Following the installation by the client of a welded DN350 flange connection and a full-bore valve, we proceeded with the hot tapping operations under pressure.

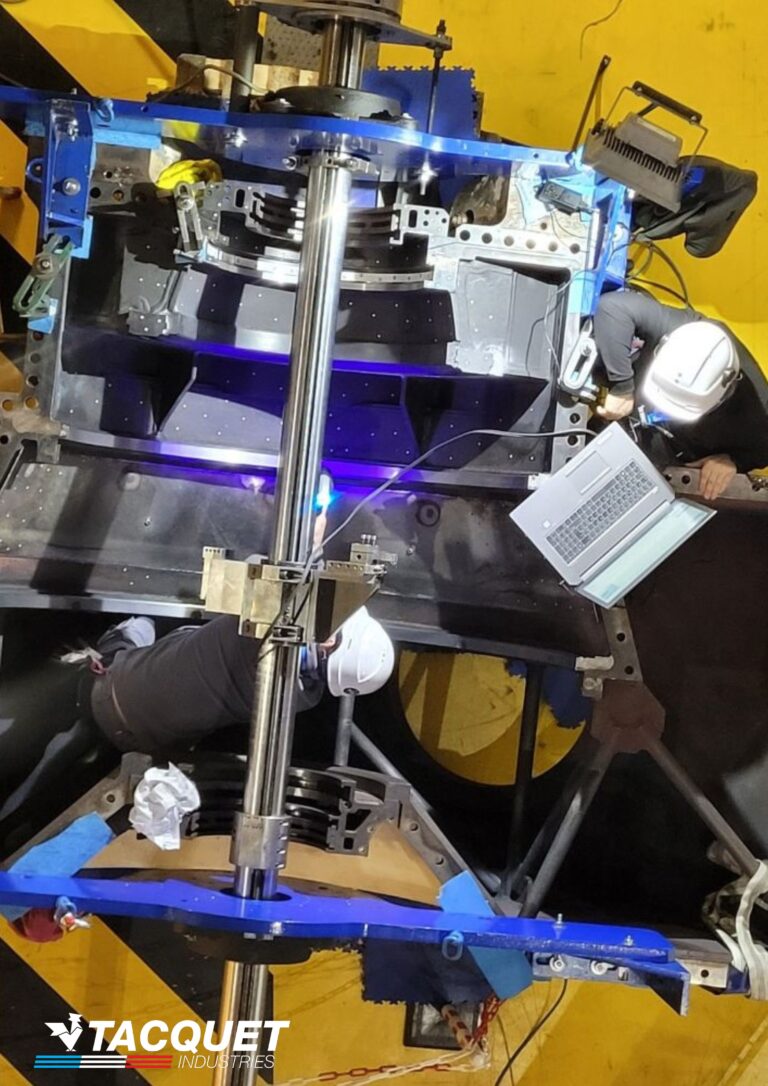

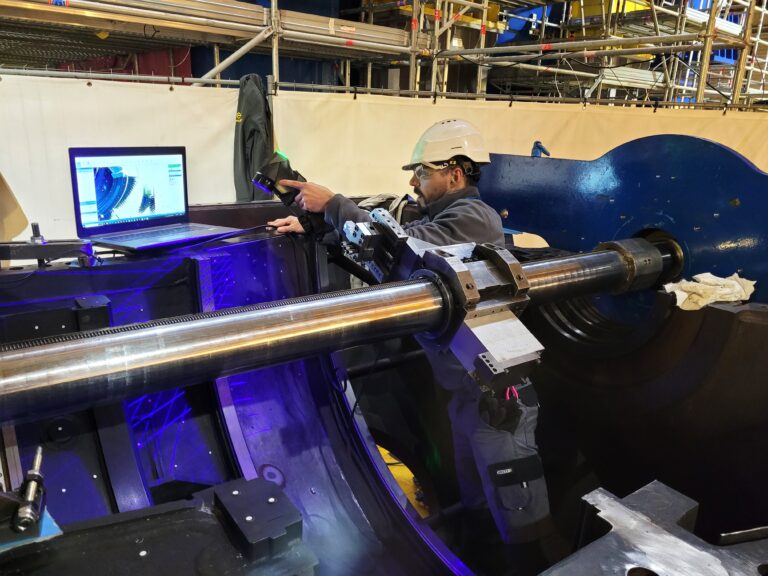

The tapping machine was mounted onto the valve and subjected to a nitrogen tightness test to ensure full safety before drilling. The cut, with a diameter of 324 mm, was performed with precision, and the coupon was returned to the client at the end of the intervention.

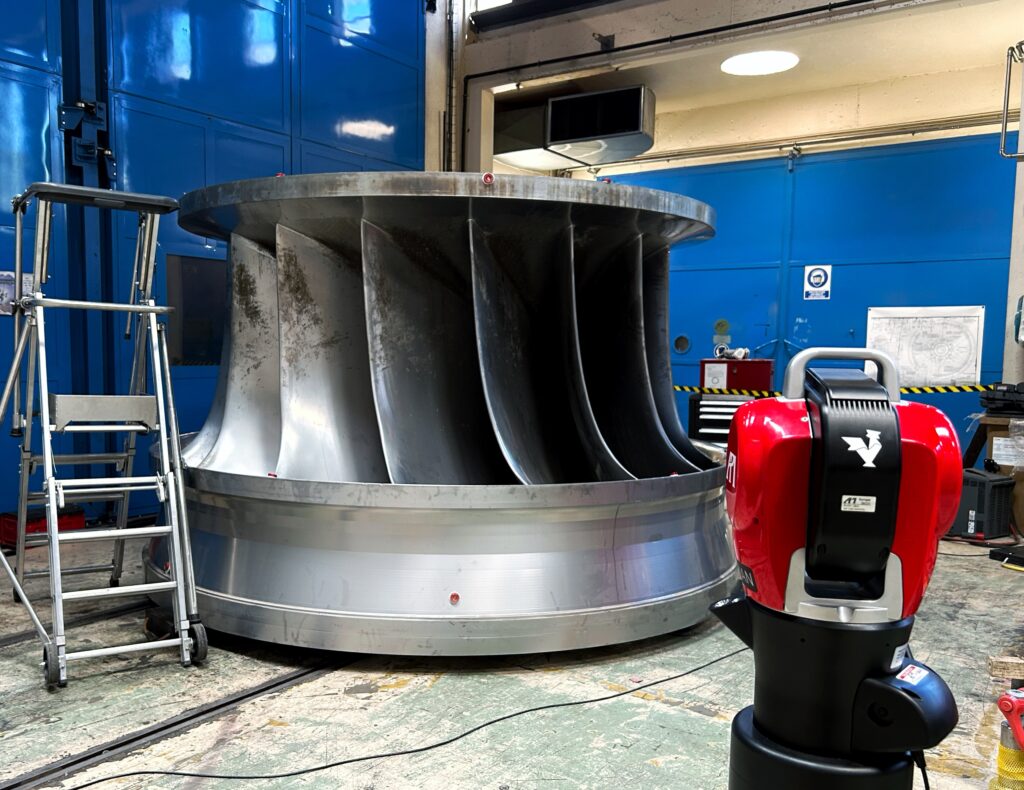

In the case of rolled or spiral-welded headers, an internal reinforcement is systematically installed to prevent any equipment blockage and ensure safe execution.

This operation highlights our expertise in large-diameter live tapping, combining technical precision, safety, and compliance with sanitary standards for potable water networks.

Intervention du 22 octobre 2024