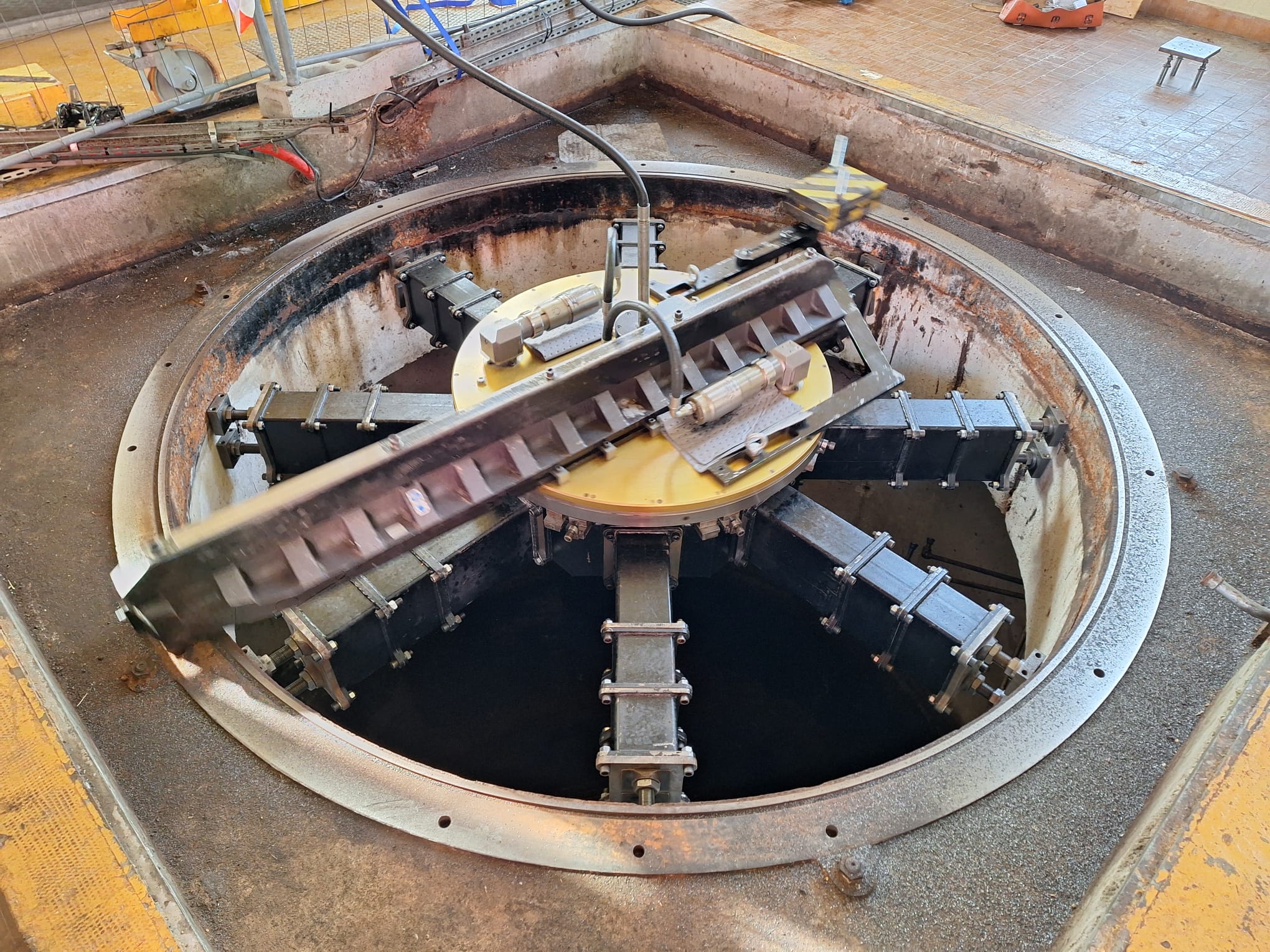

On-site re-machining on crusher assembly

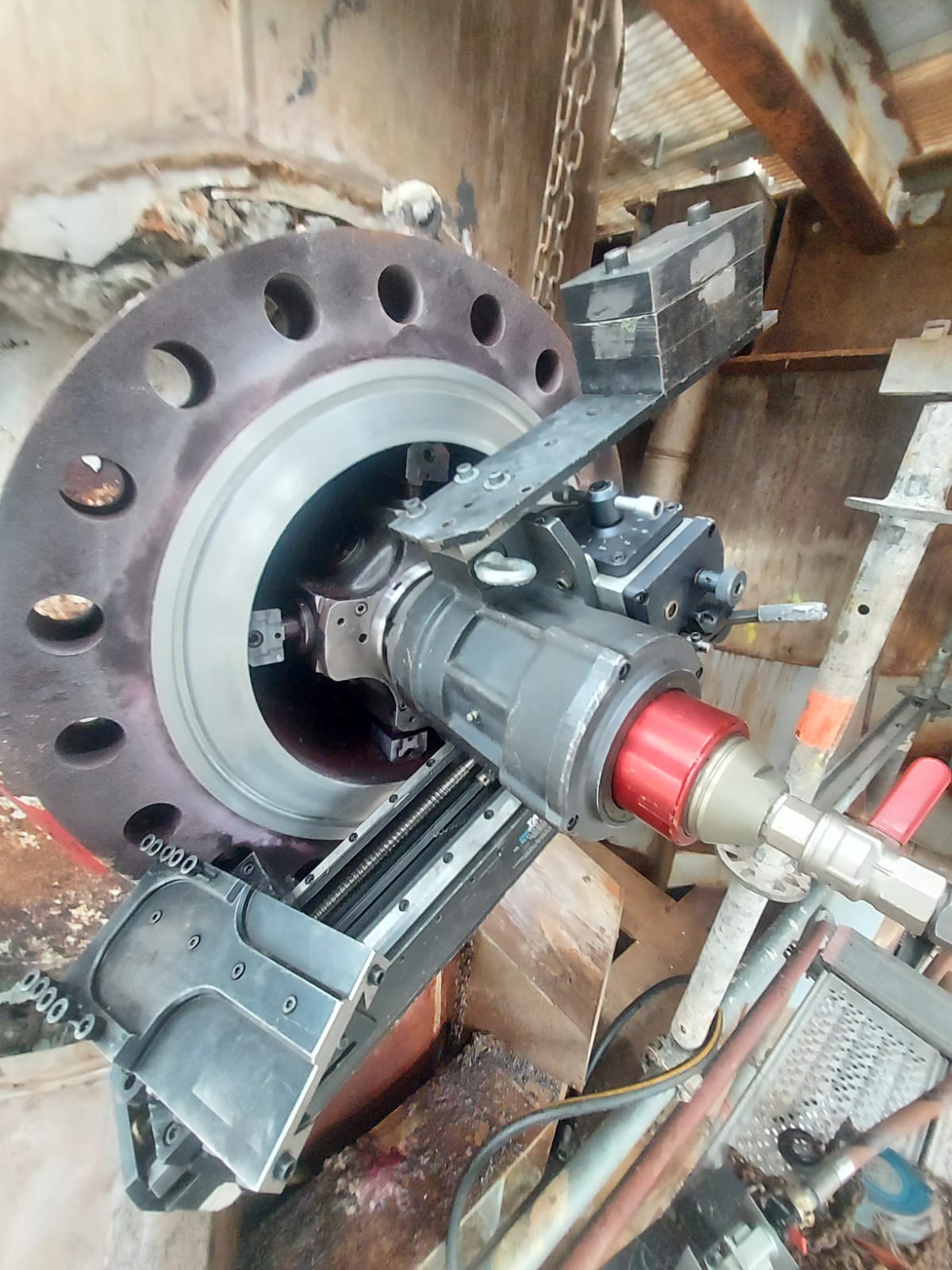

Re-machining on Crusher Shaft

A precision intervention was carried out on a Ø1200 mm crusher shaft, specifically targeting the re-machining of the journal over a length of 440 mm. The goal of this operation was to ensure the required geometrical characteristics and surface finish for optimal in-service performance.

The task involved careful grinding of the journal to achieve a surface roughness (Ra) between 0.3 and 0.4 μm, in full compliance with the technical specifications for such large-scale components. This high level of finish is essential to ensure a reliable interface with mounted elements and to minimize premature wear or friction.

This operation is part of a broader quality assurance and reliability approach for critical surfaces, ensuring that machined components meet the mechanical requirements of the equipment.

March 2024

ORBITAL GRINDING