8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

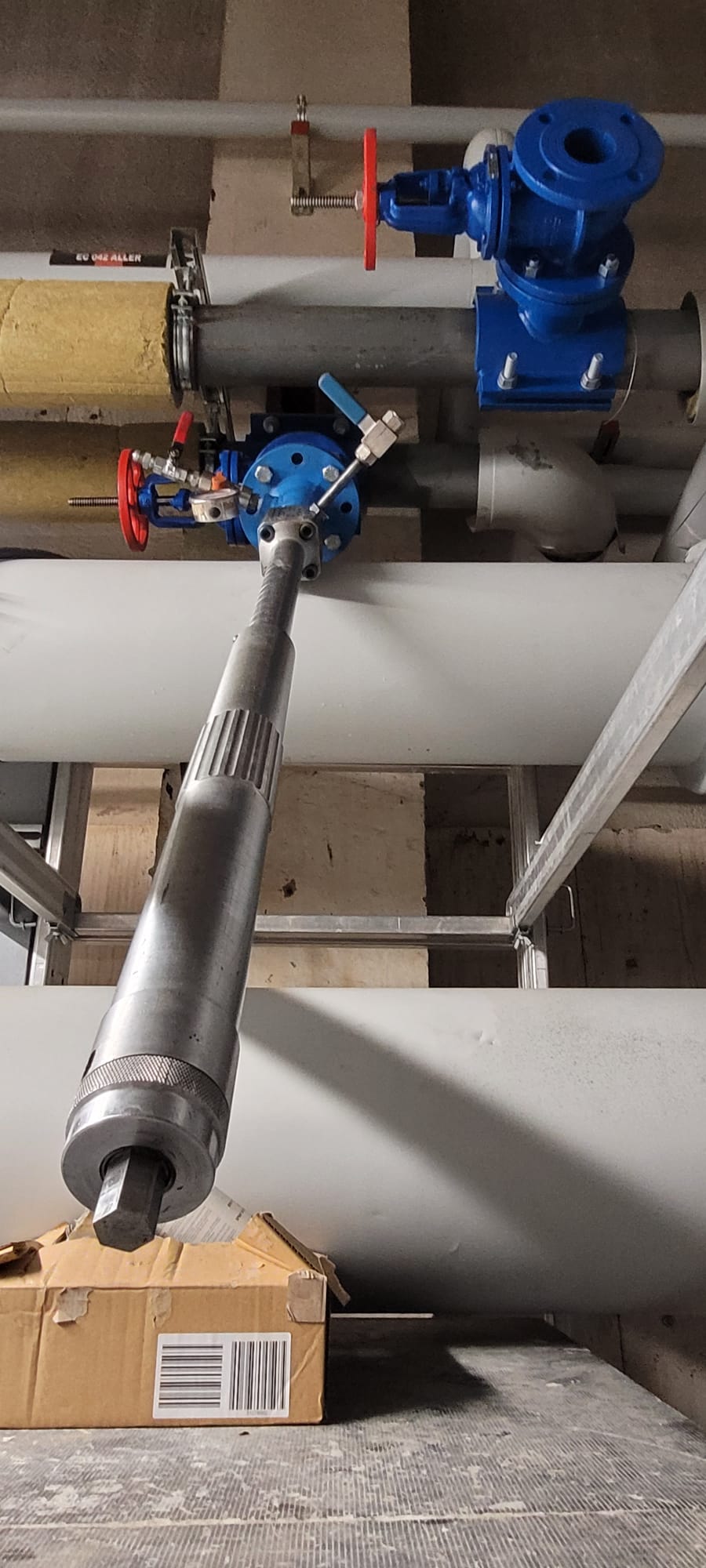

Two DN65 Hot Taps on DN100 Hot Water Header

As part of an intervention on a pressurized hot water network, our teams successfully carried out two DN65 hot taps on a DN100 header, without interrupting service.

Following insulation removal by the client and precise location marking, we installed two mechanical saddles on the cleaned and prepared header.

Each tapping point was fitted with a DN65 PN16 full-bore valve. Our technicians then mounted the drilling machine, followed by a nitrogen tightness test to ensure the system’s integrity.

The under-pressure drilling (Ø 60 mm) was performed with precision, and the coupons were returned to the client.

This operation was completed with the highest level of rigor and in compliance with safety standards, ensuring uninterrupted operation of the network and providing a reliable solution for future tie-ins.

13 febuary 2025