8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

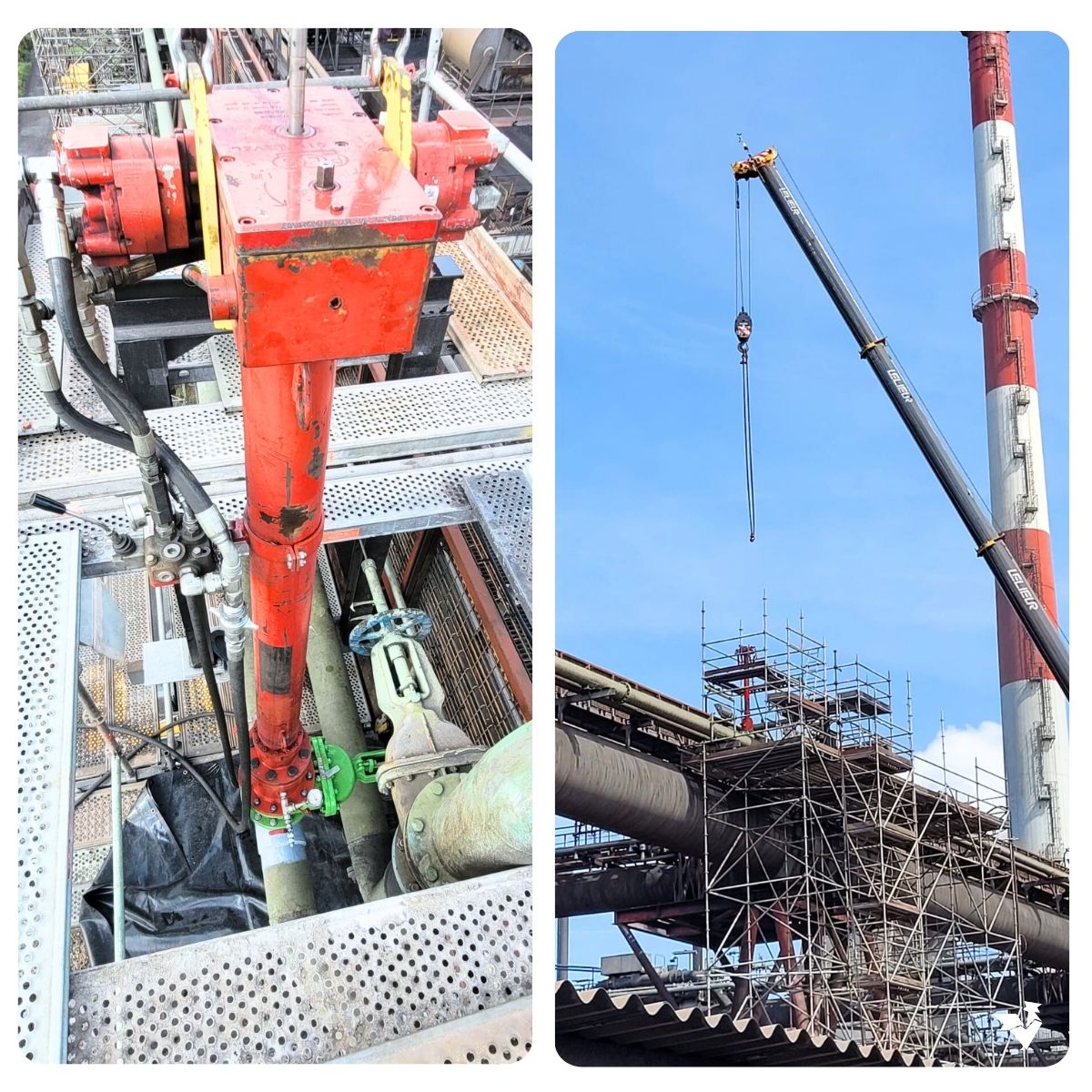

Execution of 10 Hot Taps on an Ammonia Water Network

As part of a large-scale technical operation, our teams carried out 10 hot taps on an ammonia water network, on headers ranging from DN200 to DN500.

The entire operation was conducted in a demanding environment—under pressure and at controlled temperature—with a high level of precision and safety.

We provided all fittings, including calculation notes, NDT inspections, gaskets, and bolting, in full compliance with the client’s technical specifications.

Hot taps were distributed as follows:

• 2 DN200 taps on a DN200 header

• 2 DN300 taps on a DN300 header

• 2 DN300 taps on a DN400 header

• 4 DN350 taps on a DN500 header

Each tap was preceded by a nitrogen tightness test to ensure system integrity. Our hot tapping machines were then mounted on full-bore valves to perform pressure drilling in a fully controlled manner.

This operation involved access constraints, heavy handling, and a sensitive environment (ammonia water at 68–75°C under 4 to 6.5 bar), and highlights our ability to efficiently operate on complex industrial installations, while meeting the highest technical and safety standards.

26 august 2024