8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

Geometric Inspection and Adjustment of Mounting Plates

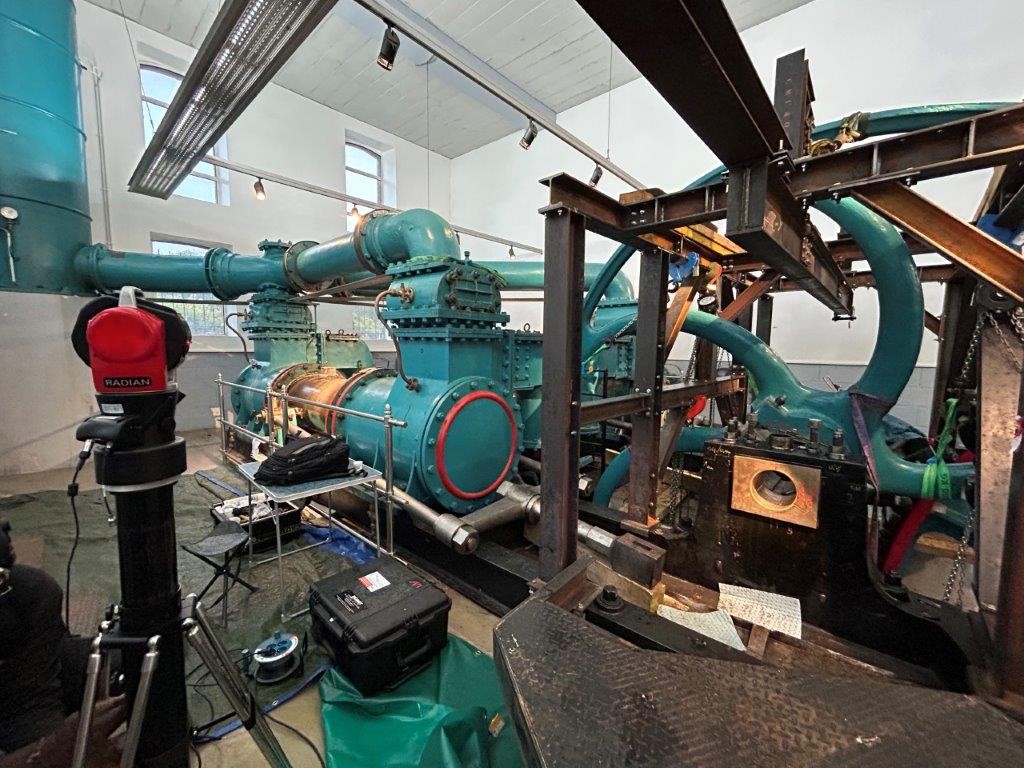

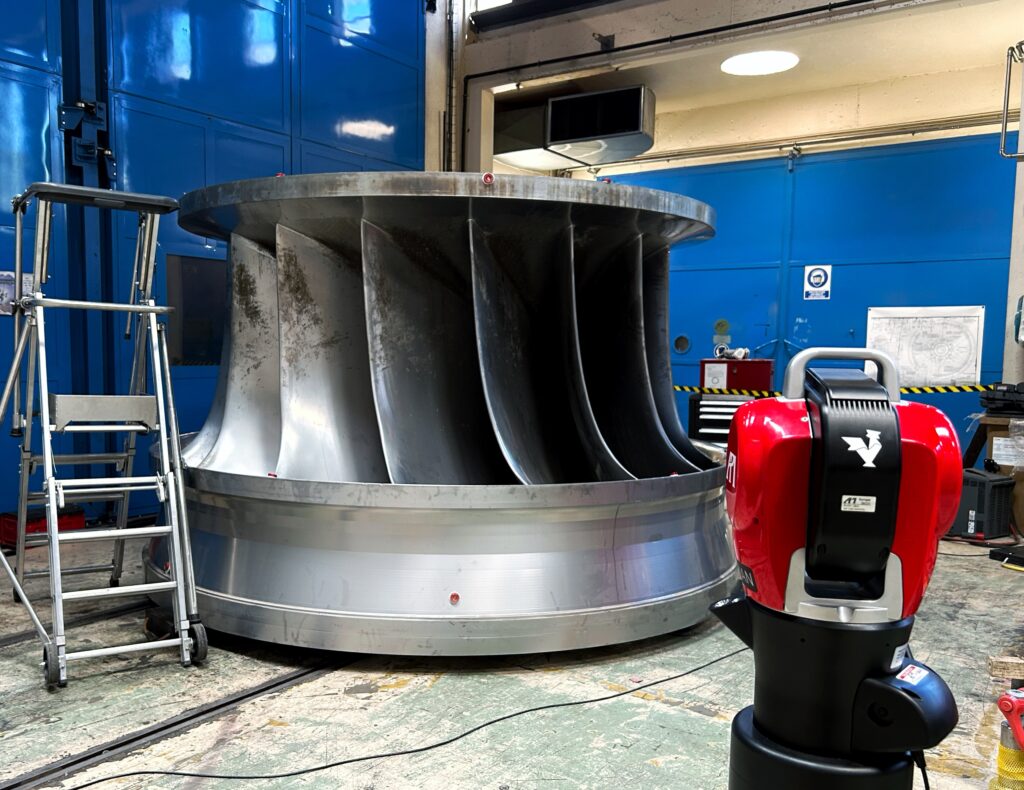

As part of an on-site intervention, a complete metrological inspection was carried out on two flanges of a gearbox (alternator side and turbine side) within the industrial environment of the Veolia Valbom unit in Bègles.

The objective of this operation was to check the flatness deviations of the flanges in their original position, record their altitudes, and perform the necessary adjustments through machining. The intervention took place in several phases: initial measurements, mechanical adjustment phase (using a milling arm), and final inspections after machining.

The measurements were carried out using a high-precision laser tracker, with corrections applied to account for the site’s thermal conditions. The surfaces were inspected according to a defined reference frame, ensuring consistency across all measurements.

Following the analysis and adjustment phases, the required values were provided to the machining teams, who made the necessary adjustments in accordance with the specified requirements. The geometry of the components was re-verified after the intervention, confirming compliance with expectations.

This type of service is part of a reliability approach for mechanical interfaces, ensuring precise assemblies optimized for operational performance.

Intervention of 22 August 2024

TRACKER LASER