8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

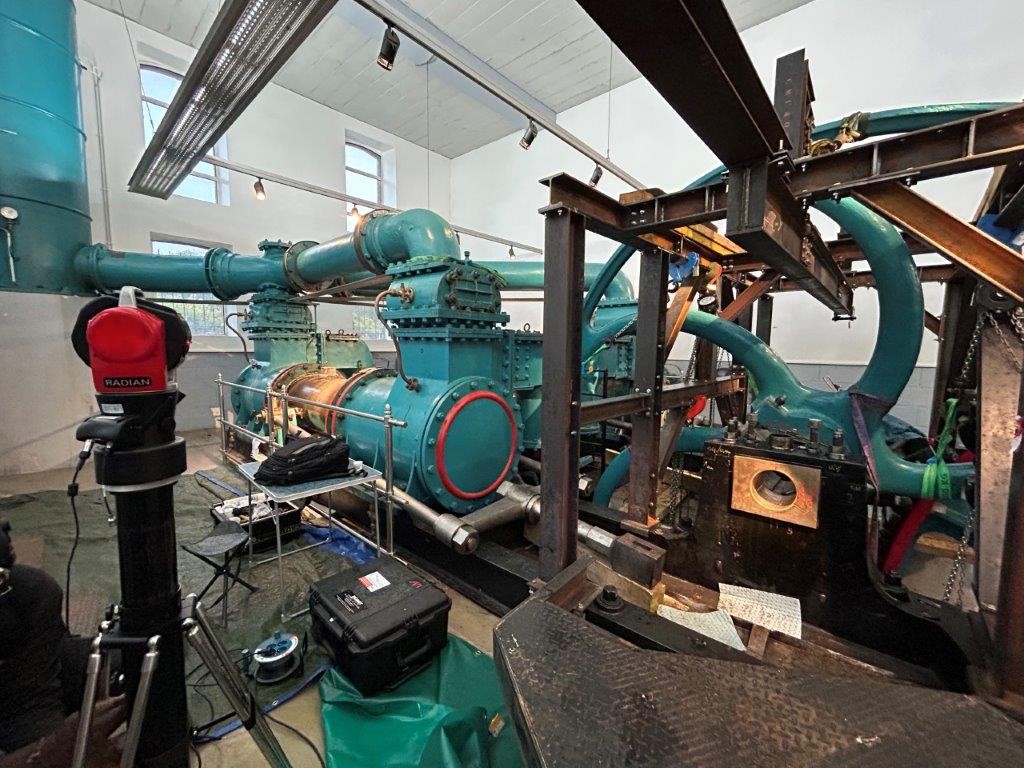

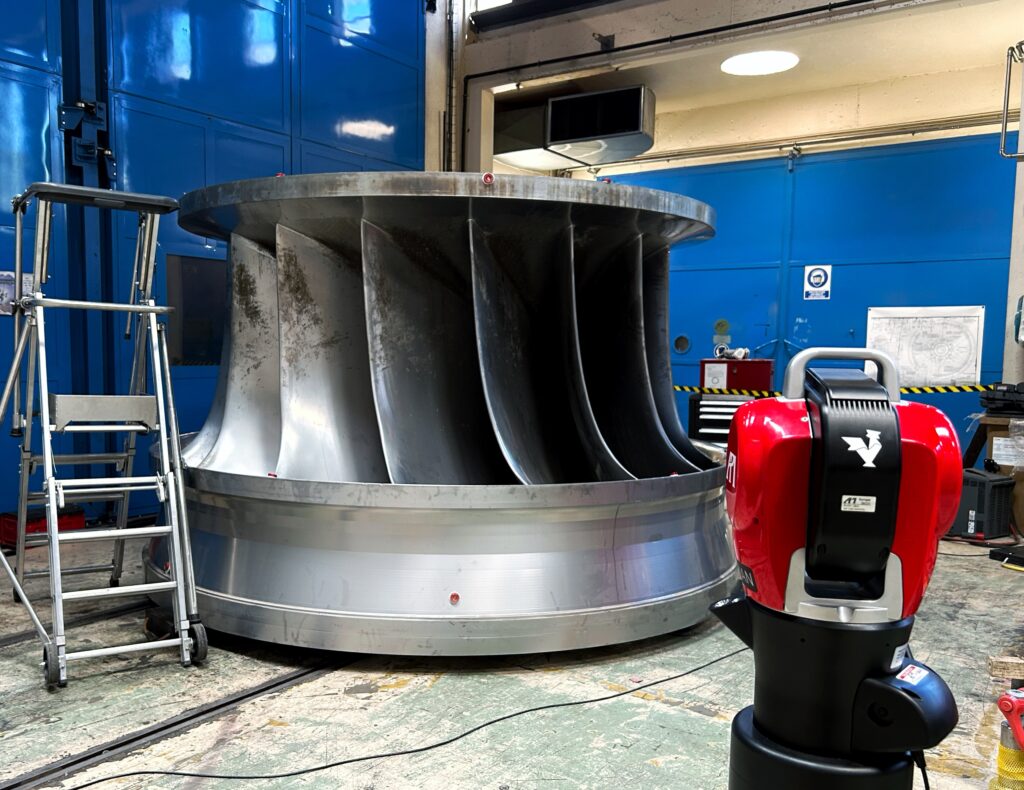

Adjustment and Geometric Inspection of Rotor

A metrology inspection was carried out on the rotor as part of an on-site geometric alignment procedure. The main objective was to check the key dimensions of the assembly and verify the alignment of the poles.

The measurements were performed using a laser tracker, with a reference frame constructed around the axis of rotation, using the shaft journal as the origin. This reference system enabled precise analysis of the rotor’s geometric characteristics, including profiles, alignments, and the relationships between various sections.

Each pole was inspected at three different heights to assess the consistency of their positioning and to validate the uniformity of the radii. This work ensured precise adjustment of the assembly in line with the installation’s requirements.

The inspections confirmed the geometric compliance of the equipment. As a result, the rotor was successfully aligned and finalized under optimal conditions at the end of the intervention.

Intervention of August 2, 2024

TRACKER LASER