8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

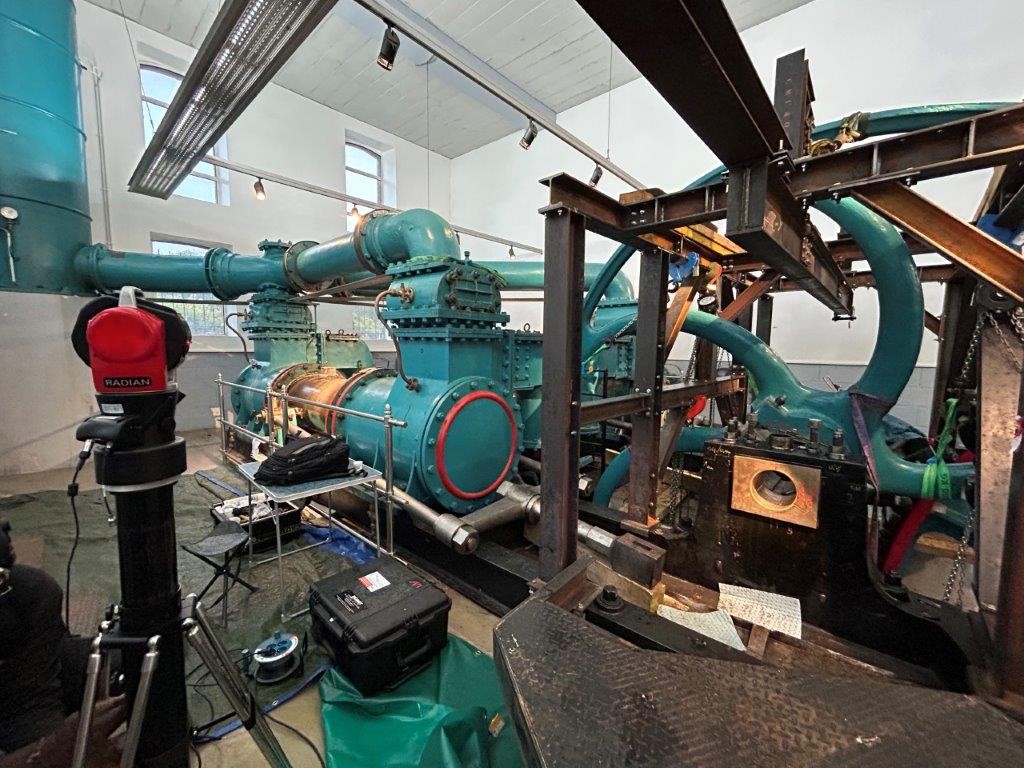

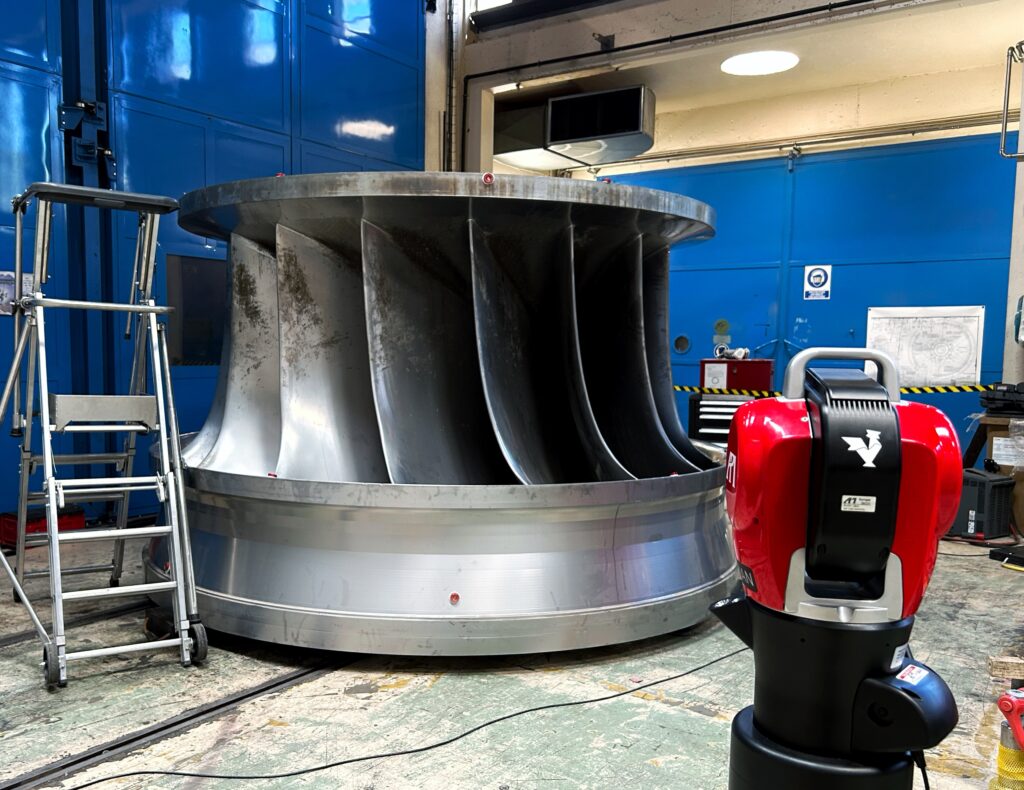

Metrological Inspection of a Crankshaft Line and Crankshaft

A metrology operation was carried out on the crankshaft line and the piston compressor crankshaft, as part of a high-precision geometric inspection. The intervention was performed directly on-site, with the objective of verifying the dimensional conformity of the mechanical components prior to commissioning or reassembly.

Measurements were taken using a laser tracker, enabling detailed analysis of surface conditions, support geometry, and overall shaft alignment. The campaign covered all bearings along the line, with multiple measurement series to validate result stability.

The crankshaft was also thoroughly inspected, including journals and crankpins, to ensure proper integration within the overall assembly and compliance with design tolerances.

All scheduled measurements were successfully completed, validating the functional geometry of the inspected components and confirming their compliance with project specifications.

Intervention of 20 November 2024

TRACKER LASER