8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

Labyrinth Inspection and Adjustment

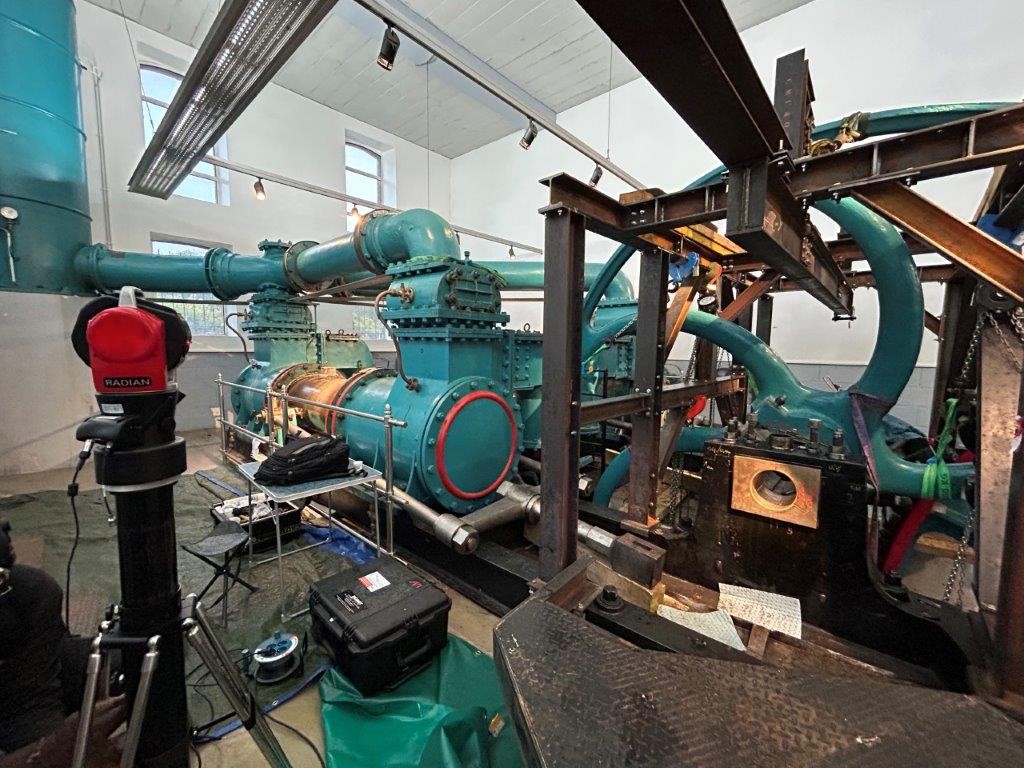

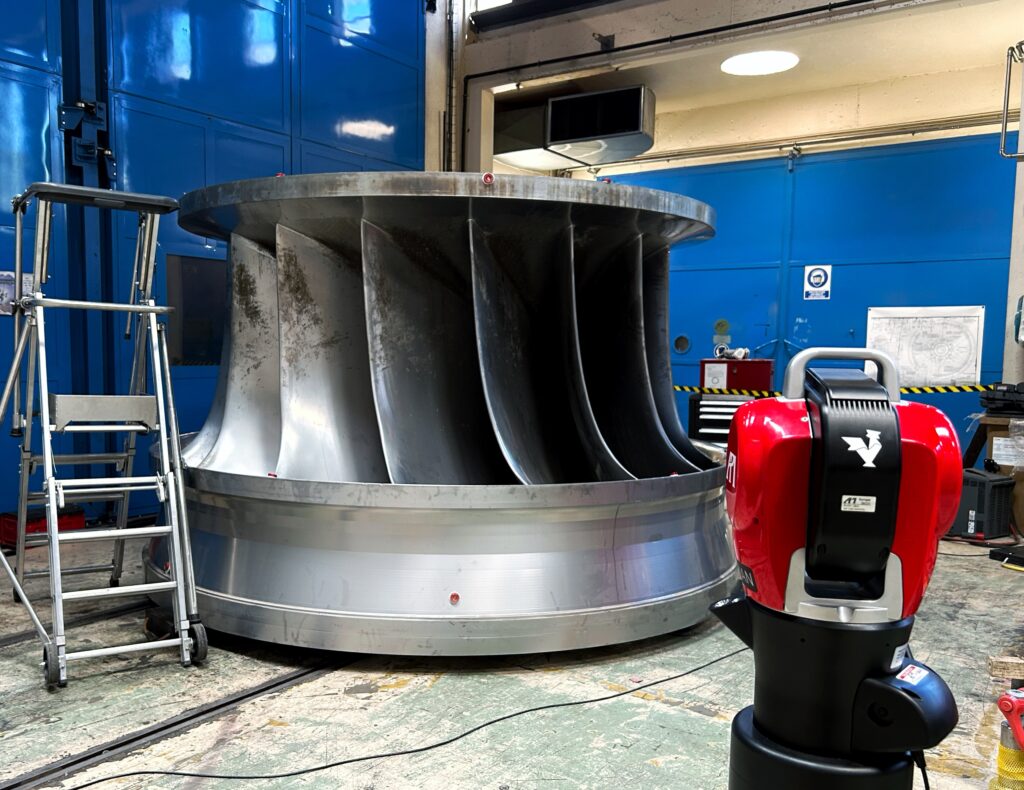

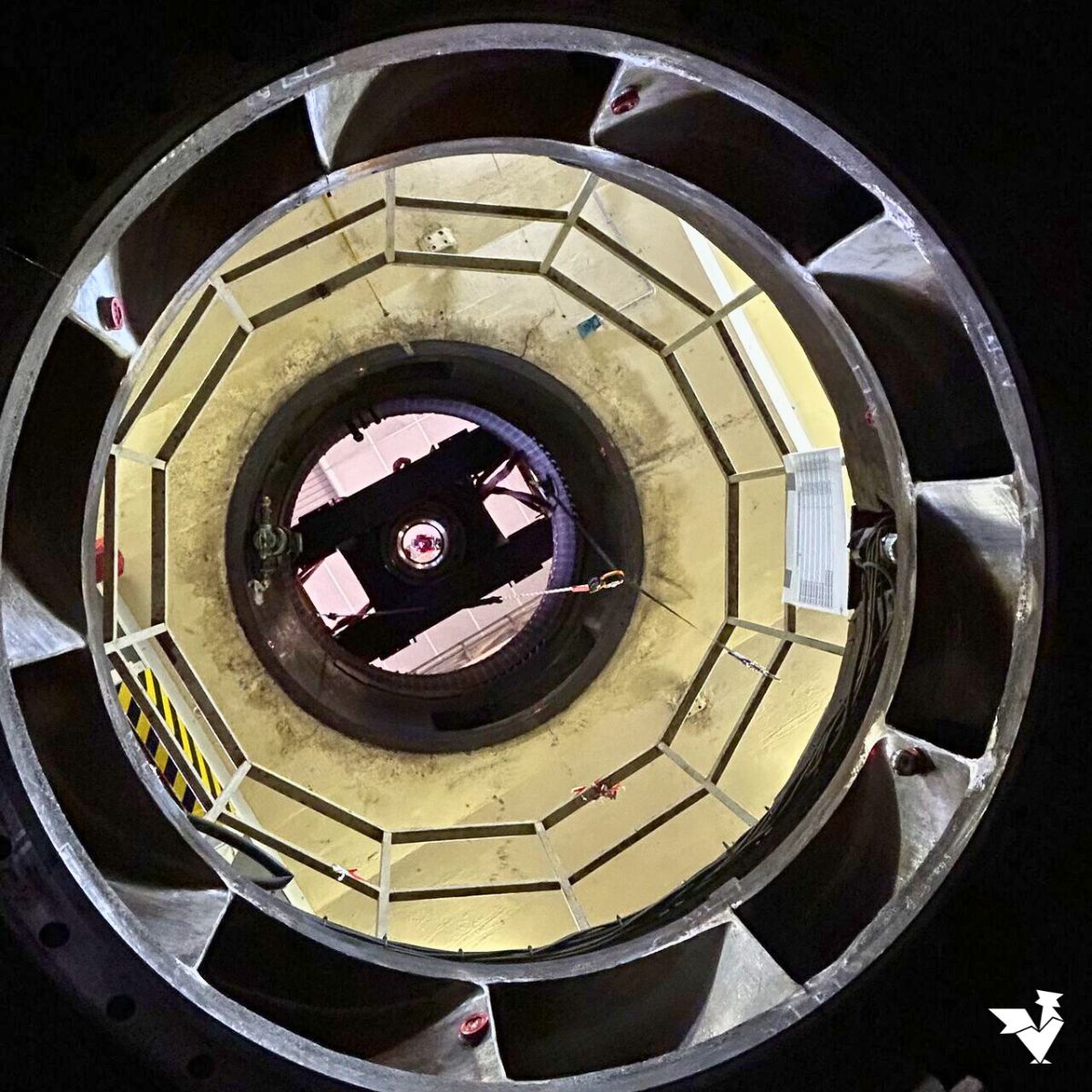

As part of a technical on-site intervention, a complete metrology inspection was carried out on the fixed parts of unit G1, followed by an adjustment and finishing phase. The operation took place over several days and involved various stages of measurement, machining, and final validation.

The process began with an initial dimensional survey to assess the condition of the component prior to intervention. A machine adjustment phase was then implemented to ensure precise surface preparation before cladding. This was followed by finishing machining operations and a final inspection after surface treatment, all performed in a controlled industrial environment.

Each stage was accompanied by rigorous tracking of geometric references, using a reference system adapted to the functional orientation of the part. A laser tracker measurement system was used to ensure the required precision at every step of the process.

In parallel, a final dimensional inspection was carried out on the entire G1 unit, including checks on critical geometries, assessment of angular positions of drilled holes, and overall validation after machining. All scheduled measurements were completed in accordance with the control plan requirements.

This operation is part of a broader effort to restore technical compliance and secure the mechanical components of the plant, ensuring their optimal integration within the overall system.

Intervention of 20 December 2024

TRACKER LASER